EFFICIENT, RELIABLE AND VERSATILE DIRECT EXPANSION COOLING SYSTEM

Lambda DX/DXU is the next generation direct expansion air conditioners family based on microchannel evaporator technology and designed for high availability applications. This air conditioning system provides precise and reliable control of indoor temperature, humidity, and airflow for proper operation of cooled facilities. In addition to the wide range of options, this gives our customers the flexibility to design solutions, matching increasingly complex requirements as closely as possible.

With microchannel evaporators, the Lambda DX/DXU range offers the highest efficiency level available today, as well as a number of benefits, including reduced weight, smaller footprint, lower refrigerant charge and demand-responsive performance.

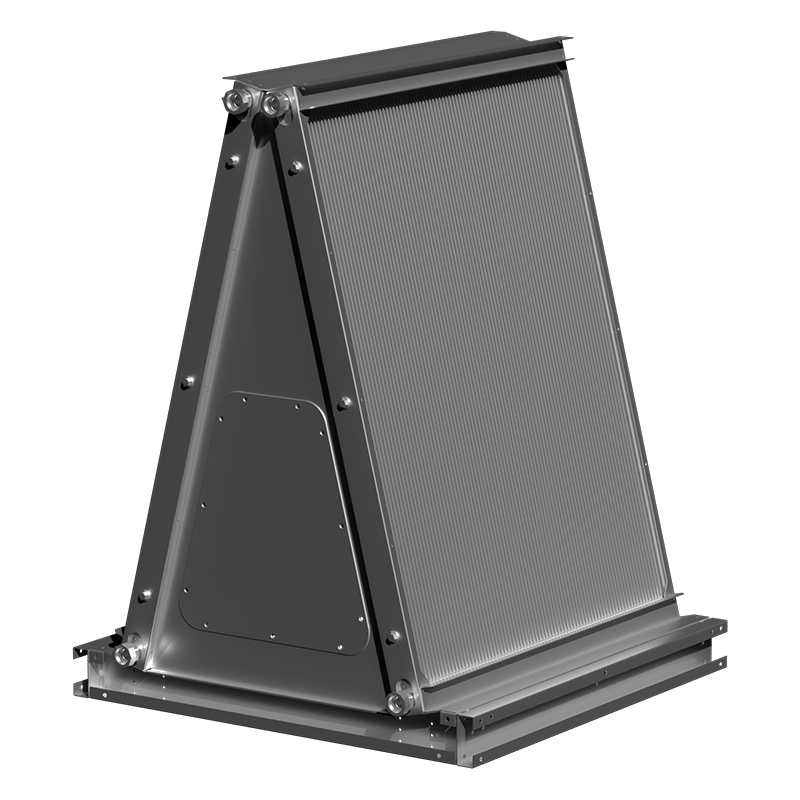

DUAL MICROCHANNEL EVAPORATORS

Lambda DX/DXU air conditioning units based on newly developed microchannel evaporators with an advanced design that combines high-performance flat tubes, state-of-the-art airside fins and ultra low-pressure manifolds with integrated refrigerant distributors.

The unique geometry of the manifolds and refrigerant distributors make it possible to feed the microchannel tubes equally for evaporation and ensures consistent and predictable heat transfer. Vertically-oriented microchannel tubes allow free condensate water shedding.

In combination with doubled area A-shaped design, microchannel evaporators permit many benefits to be achieved, including low airside pressure drops, higher cooling capacity, remarkably less weight and reduced refrigerant charge.

HIGHER ENERGY EFFICIENCY

LOWER WEIGHT

REDUCED REFRIGERANT CHARGE

SCROLL COMPRESSORS

OPTIMIZED FOR REFRIGERANT R410A

The scroll compressors employed in our air conditioners’ design are the result of large-scale research and development efforts underway since 1979. These efforts have led to the production of the most advanced scroll compressor design currently available for air-conditioning applications.

Dual compressor Lambda DX/DXU units are perfectly suitable for both constant and variable heat load applications. On-board electronics provides compressor protection, diagnostics and communication capabilities.

The customers of Lambda DX/DXU systems with R410a-optimized scroll compressors can benefit from the quiet operation, unmatched reliability and low operating cost.

DUAL REFRIGERATION CIRCUIT

Lambda DX/DXU precision air conditioning units feature two independent refrigerant circuits each connected to its own microchannel evaporator, thus allowing the maintenance tasks to be carried out with the cooling system at power.

Through the use of microchannel evaporator, the refrigerant charge of the Lambda DX/DXU air conditioners is significantly reduced in comparison to legacy finned tube evaporator designs. Each refrigerant circuit equipped with electronic expansion valve (EEV) which has the function of regulating and optimizing the refrigerant quantity to the evaporator according to current requirements. Lambda DX/DXU features a refrigerant leak detection system, which is becoming a high priority for many customers, especially considering the potential for loss if a major leak renders a cooling system inoperable.

All the components of Lambda’s refrigerant circuit are located within the separate compartment, thus allowing easy access for maintenance and servicing.

SOPHISTICATED CONTROLS

FLEXIBILITY IN APPLICATIONS

The control system of Lambda DX/DXU air conditioners is the latest generation controller with the logic specially developed for direct expansion precision cooling units. The software offers advanced control functionality for stand-alone and network operations, monitoring and diagnostics capabilities – locally or remotely.

Users can adopt various control strategies based on either continuous temperature control, or on-demand airflow control, or constant pressure control by maintaining a pressure differential between the cold and hot aisles.

ADVANCED EC FANS

Lambda DX/DXU features new radial fans with unique blade geometry and offers increased airflow based on reduced size and wider efficiency range. In combination with EC-motors with integrated control functionality, a communication interface, and overtemperature protection, these fans provide unbeatable energy efficiency, maximum flexibility, and the lowest possible sound emission. EC motor technology produces significant savings at both full load and part load operation. Lambda’s EC-motors are maintenance-free and have a longer lifetime in comparison to brushed motors. The fans are also fully compliant with the requirements of Energy-related Products (ErP) 2015 Directive.

The range includes Lambda DX models with an easily accessible integrated fan compartment and additional noise insulation, making these units one of the quietest precision air conditioners on the market. Lambda DXU models feature an underfloor fan compartment with free radial air distribution, which further improves fan efficiency.

PRODUCT SPECIFICATIONS

|

Capacity [kW] |

35 … 95 |

|---|---|

|

Cooling source |

DIRECT EXPANSION |

|

Compressors |

SCROLL |

|

Refrigerant |

R410A |

|

Energy efficiency (EER) |

UP TO 4.06 |

|

Fan motors |

EC |

|

Heat exchangers |

MCHE |

|

Evaporation control |

EEV |

|

Refrigeration circuits |

2 |

|

Humidity control |

AVAILABLE |

|

Warranty |

3 YEARS |