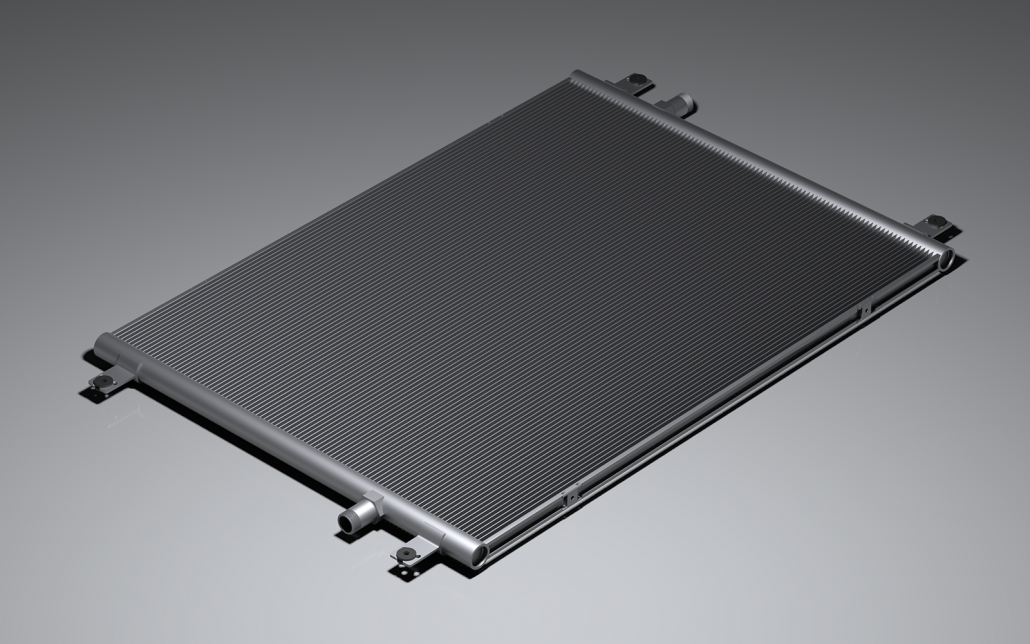

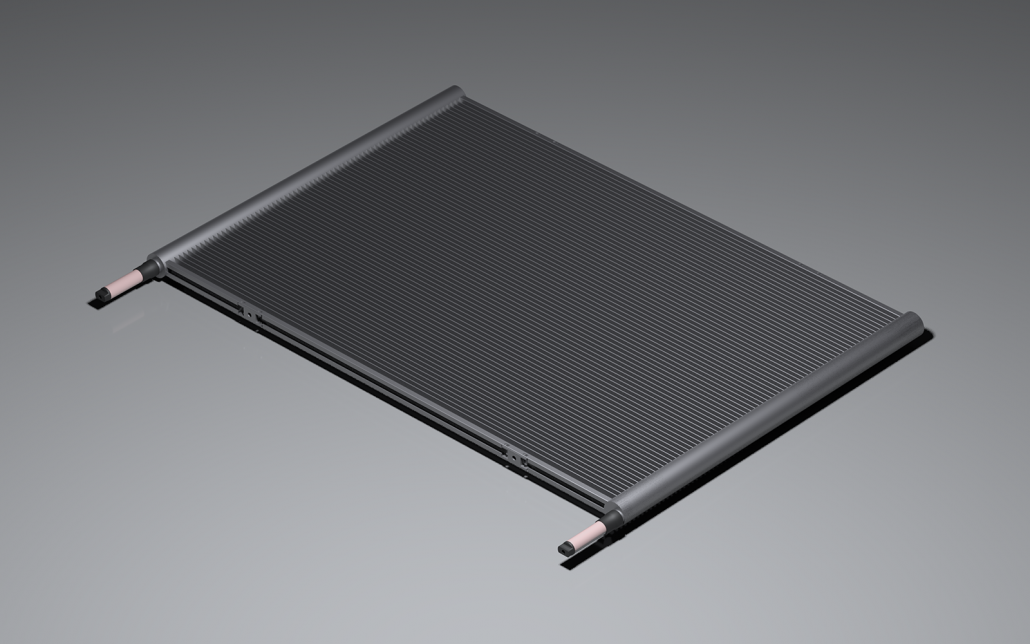

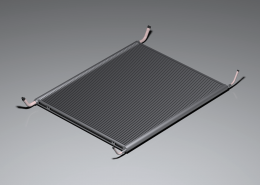

HIGH-PERFORMANCE MICROCHANNEL COILS FOR HVAC APPLICATIONS

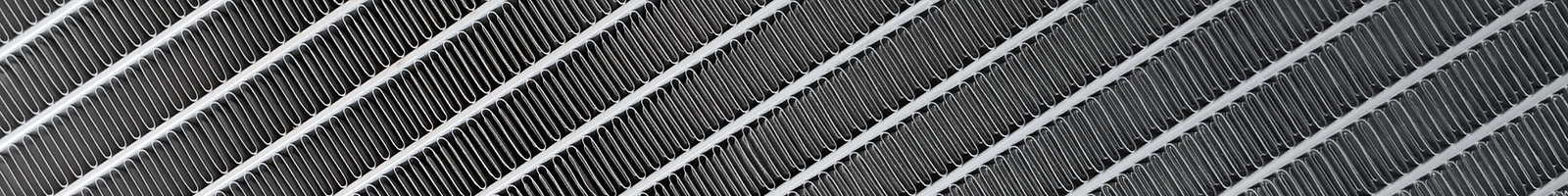

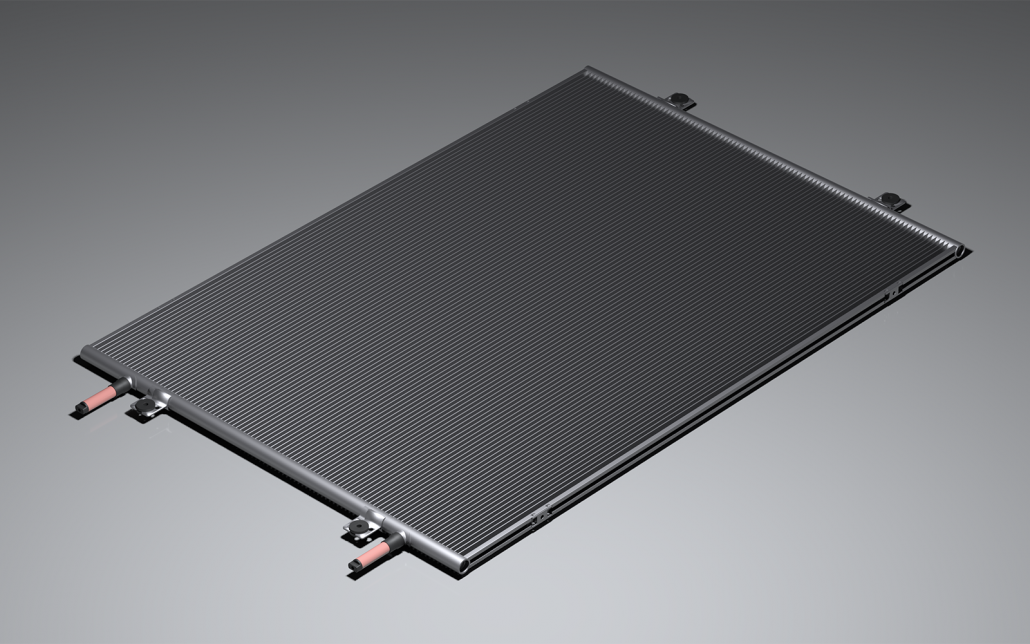

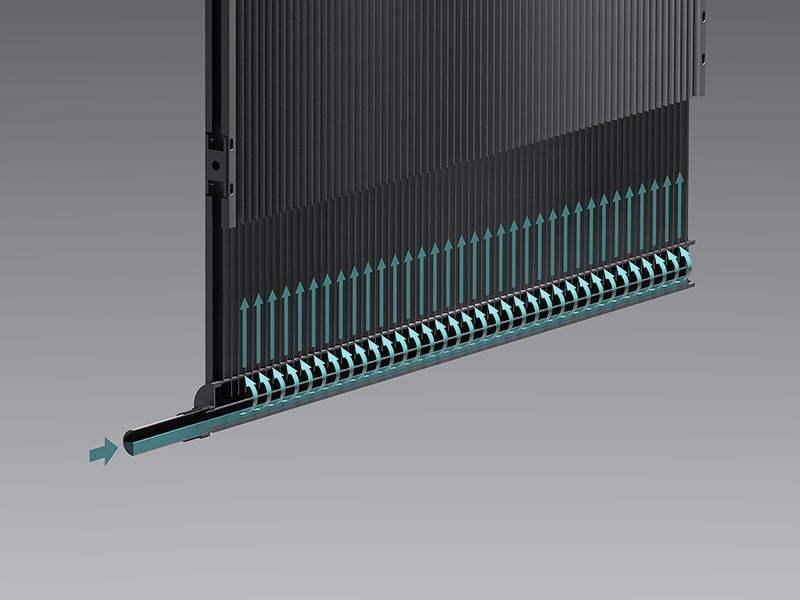

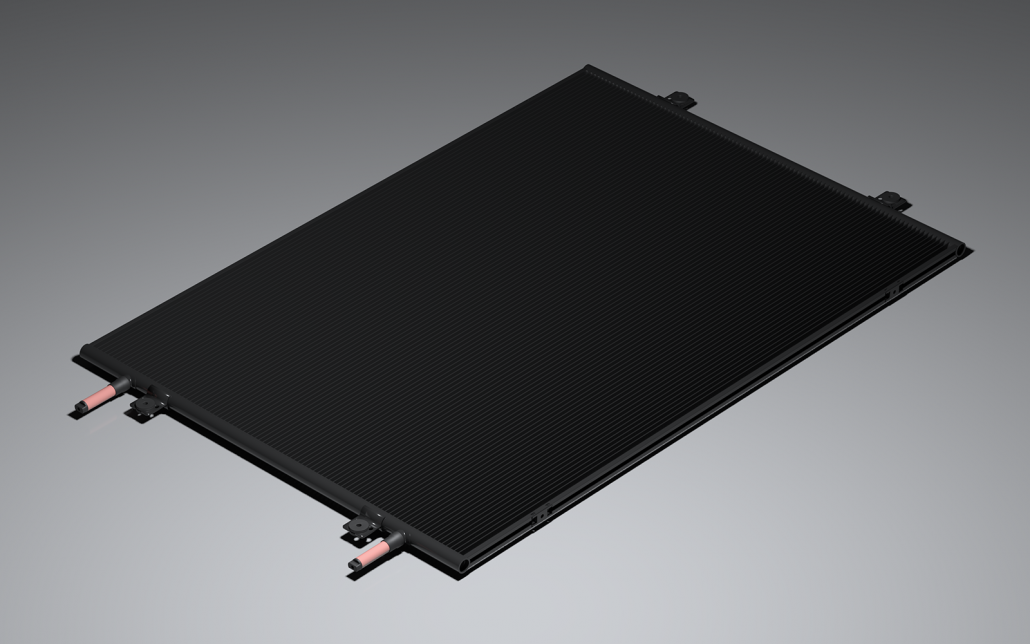

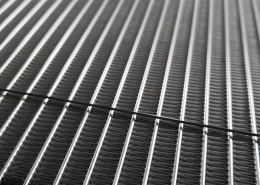

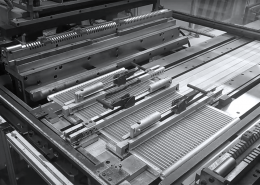

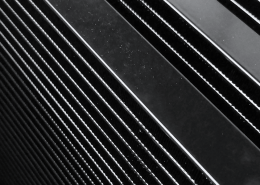

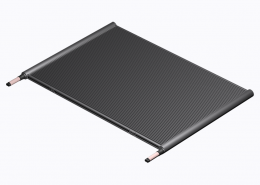

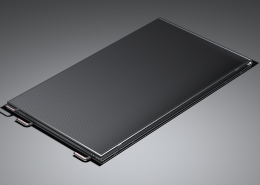

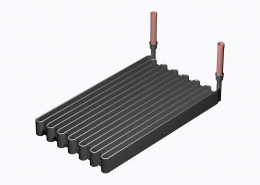

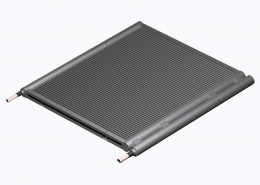

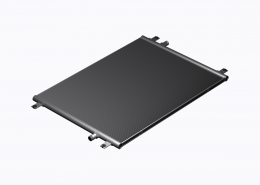

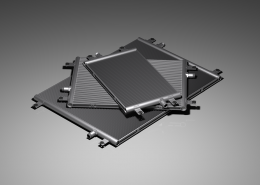

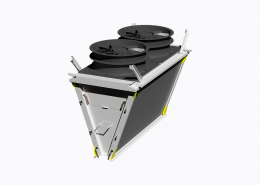

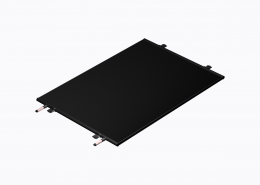

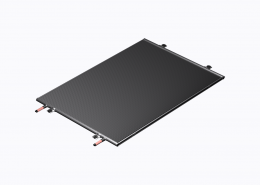

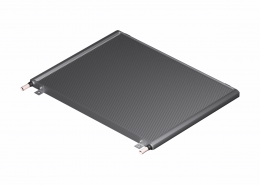

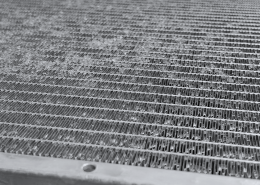

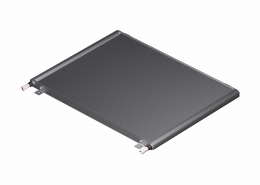

We manufacture innovative, next-generation aluminium microchannel heat exchangers that provide high heat transfer performance, excellent flexibility, lower internal volume, and smaller size and weight: features and capabilities not found in traditional finned tube heat exchangers.

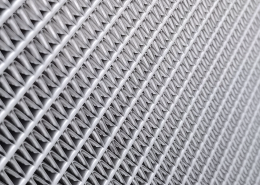

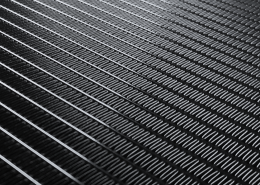

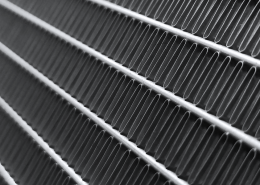

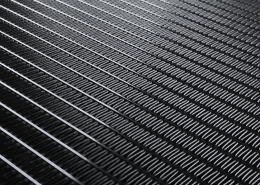

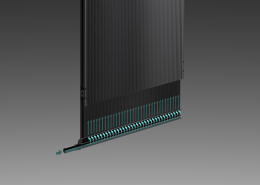

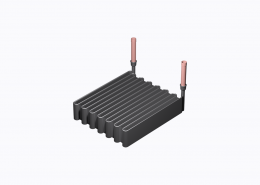

Microchannel technology offers improved performance by increasing air-side heat transfer between fins and ambient air, heat conduction between fins and flat tubes, and refrigerant-side heat transfer between tubes and refrigerant resulting in 20 to 40 percent higher overall performance compared to finned tube designs.

Importantly, our microchannel heat exchangers perfectly match any application, be it condenser coil, evaporator, water coil, or coil for use in heat pumps – owing to innovative design based on extensive research and development.