Formicary corrosion

Approximately 10% of heat exchanger failures are connected with leaks caused by formicary corrosion. Organic compounds remain on copper tubes during manufacturing and fabrication of the HVAC equipment, are able to advance to formicary corrosion only with the simultaneous presence of moisture, oxygen, and acids. When all elements are present on the copper tube, the corroding agent will begin to penetrate the tube surface via small cracks that exist in the oxide film covering the tube. This process forms a micro anode and causes the copper to begin dissolving, starting the formation of the pits.

Formicary corrosion is unobservable to the unaided eye, which makes it difficult to detect its presence before the damage is already severe and causes a leak. The problem is most prominent in regions with high humidification levels. A high level of humidity causes the presence of more water to react with the other components in the air and enhances corrosion to the alarming rates.

Preventing Formicary Corrosion

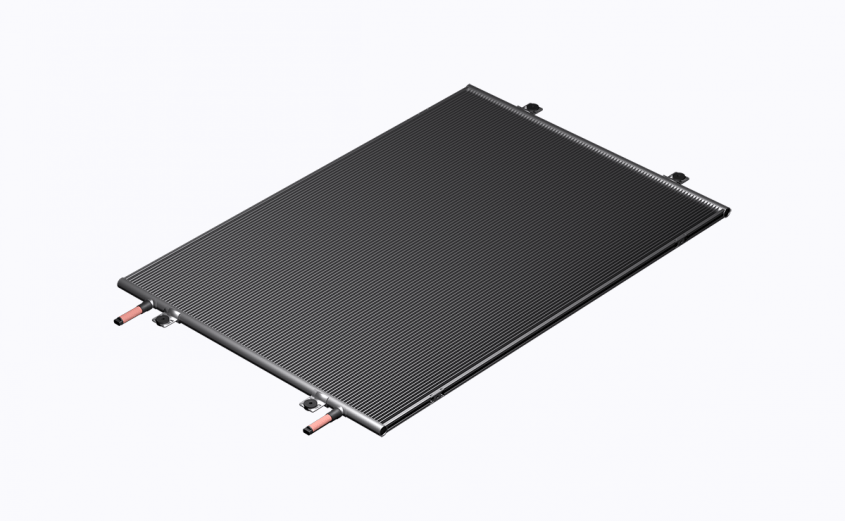

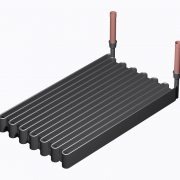

In order to prevent formicary corrosion, one of the four factors – moisture, oxygen, acid, and copper – must be excluded. It is impossible to remove oxygen, moisture, and acid from the environment, so that just leaves copper. Cooling products that are equipped with all-aluminium microchannel coils take copper out of the equation, thus eliminating formicary corrosion.