The dual-cool system provides thermal management from two independent cooling sources, with direct expansion and chilled water technologies, and offers a wide range of cooling solutions with a focus on either energy efficiency or system availability/redundancy.

The Delta’s microprocessor manages the system by activating direct expansion (DX) and chilled water (CW) cooling circuits in accordance with user settings: in heat load share mode or primary/backup cooling source mode with automatic changeover.

In heat load share mode, both direct expansion and chilled water cooling sources are operating in parallel under the control of the unit’ microprocessor, which allocates the workload by selecting the most efficient regime. In primary/backup mode, the customer decides which medium shall act as the primary source of cooling and which shall act as a backup, and the unit controller switches to the second source in the case of failure or engages it to cope with high heat loads.

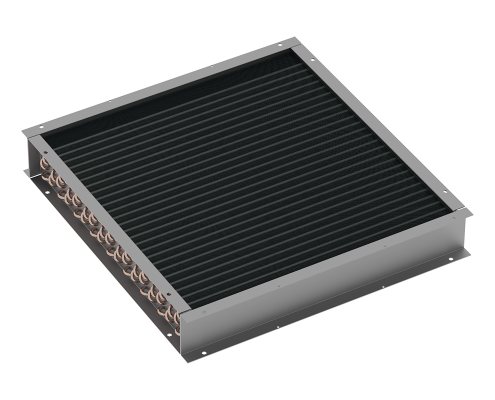

To control the capacity of the chilled water system, we equip Delta units with a motorized 2-way regulating valve.