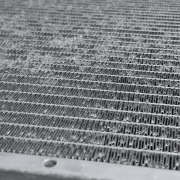

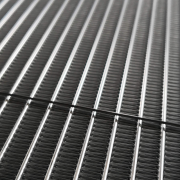

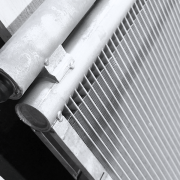

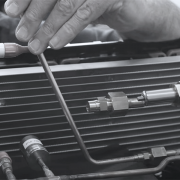

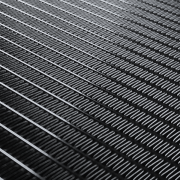

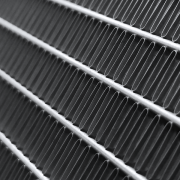

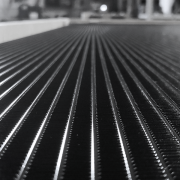

Helium leak test explained

As energy efficiency and environmental regulations tighten across the HVAC industry, leak testing has become more important than ever. With the growing shift to climate-friendly refrigerants and the adoption of compact, high-efficiency components, ensuring leak-tight systems is not only critical but also increasingly challenging.