What is e-coating and how does it work?

Introduction to E-Coating

Electrocoating—also known as e-coating, electro-deposition, or electrophoretic deposition—is a high-performance finishing process in which metal parts are immersed in a paint bath and coated through the application of electrical current.

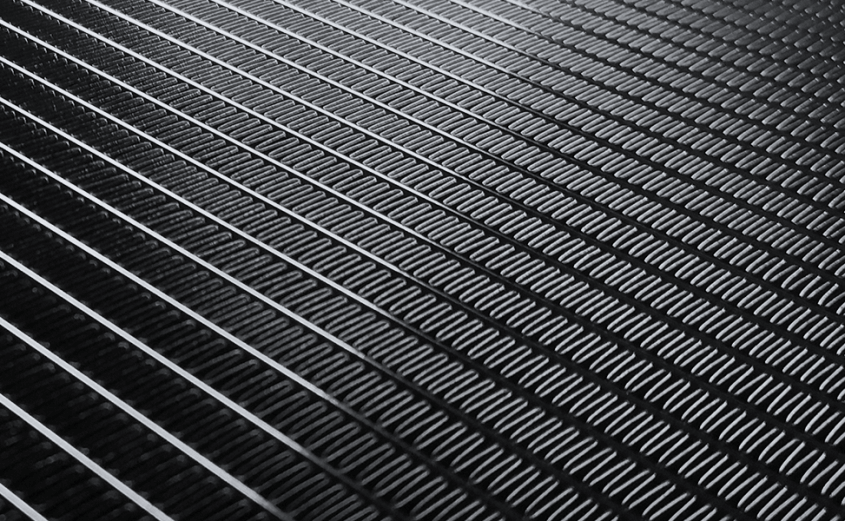

In the context of microchannel heat exchangers, e-coating is primarily used to apply a uniform, corrosion-resistant epoxy layer to aluminum components.

1. Pretreatment: Surface Preparation

Before e-coating, the aluminum surface must be thoroughly cleaned of oils, greases, and other contaminants. A robust pretreatment process is critical to achieving a durable and consistent finish.

- Zinc phosphate is the preferred pretreatment method, offering excellent corrosion resistance and promoting strong paint adhesion.

- Proper surface preparation helps maintain the purity of the paint bath and supports long-term coating performance.

2. Electrocoat Bath: Controlled Paint Deposition

During this stage, heat exchangers are fully immersed in a water-based epoxy paint bath, where an applied electrical current causes paint particles to deposit evenly onto the aluminum surface through electrophoresis. Kaltra employs a cathodic electrocoating system, in which the heat exchanger serves as the negatively charged electrode, attracting positively charged paint particles.

As deposition begins, paint solids first accumulate on the most exposed areas. As the coating builds up, it creates an insulating layer, reducing current flow to those areas and naturally shifting deposition to less accessible surfaces. This self-limiting mechanism ensures uniform film thickness and comprehensive coverage—even within intricate structures like louvered fins and narrow tube gaps.

A critical aspect of this process is throwing power—the ability of the paint to reach deep recesses within the coil geometry. Achieving complete, void-free coverage requires careful regulation of several variables:

- Voltage and current control is essential to balance penetration depth and avoid issues such as fin bridging, where excess paint blocks air pathways.

- Bath chemistry and paint formulation must be precisely maintained to ensure optimal particle mobility and stable deposition behavior.

- Immersion time is adjusted based on the coil’s geometry and required film thickness to ensure consistency across different product lines.

By fine-tuning these parameters, Kaltra ensures that the entire surface of the microchannel coil—including hard-to-reach internal areas—is coated evenly, resulting in a corrosion-resistant, aesthetically clean, and mechanically durable finish.

3. Post-Rinsing: Finish Optimization

After deposition, the parts go through a series of post-rinse stages, typically two to three:

- These rinses remove loose or excess paint.

- A final rinse with deionized water enhances the finish’s smoothness and uniformity.

4. Oven Curing: Hardening the Coating

Following rinsing, the coated heat exchangers enter a bake oven where the epoxy layer is crosslinked and cured:

- Curing temperatures range from 80°C to 240°C, depending on the specific paint formulation.

- Proper curing ensures maximum coating durability, mechanical strength, and resistance to environmental stress.

5. UV Protection: Topcoat Considerations

While epoxy e-coatings provide exceptional protection against corrosion, salt, and humidity, they have low UV resistance. For outdoor or sun-exposed applications, a UV-resistant topcoat is recommended to protect the epoxy primer and ensure long-term performance.

Process Limitations and Considerations

Although cost-effective per unit, e-coating systems are capital-intensive to build and maintain. Lines are typically optimized for a single paint formulation:

- Color changes require extensive downtime and reconditioning of the entire system.

- This makes e-coating ideal for large-scale, uniform production runs, where long-term performance is a priority.

Why Choose E-Coating for Microchannel Coils?

E-coating offers several critical advantages for aluminum microchannel heat exchangers:

- Exceptional corrosion resistance

- Epoxy cathodic coatings at 20μm withstand:

- >6000 hours in ASTM B117 salt spray test

- >4000 hours in SWAAT (ASTM G85 Annex A3)

- Epoxy cathodic coatings at 20μm withstand:

- Environmentally friendly

- Complies with RoHS, EPA, and OSHA standards

- Low VOC and minimal hazardous emissions

- Uniform, even finish

- Excellent aesthetics and consistent protection across complex coil geometries

Where Is E-Coating Recommended?

E-coating is strongly advised for microchannel heat exchangers deployed in corrosive environments, particularly where humidity, salt exposure, or industrial pollutants pose a risk to untreated aluminum components.

According to the latest ISO 12944-2:2018 standard, corrosivity categories are as follows:

- C4 – High Corrosivity

- Typical Locations: Industrial areas with high humidity, coastal regions with moderate salinity, urban rooftops, processing facilities.

- Aluminum Mass Loss: 2–5 g/m²/year.

- Recommendation: E-coating provides reliable surface protection and extended service life in these conditions.

- C5 – Very High Corrosivity (Onshore)

- Typical Locations: Highly polluted industrial areas, wastewater treatment plants, power generation sites with high humidity and chemical exposure.

- Aluminum Mass Loss: 5–10 g/m²/year.

- Recommendation: Cathodic epoxy e-coating is strongly recommended to ensure longevity and corrosion resistance in demanding onshore environments.

- CX – Extreme Corrosivity (Offshore)

- Typical Locations: Offshore oil platforms, coastal installations with continuous sea spray, subtropical/marine climates with extreme humidity and salt.

- Aluminum Mass Loss: >10 g/m²/year.

- Recommendation: In such extreme conditions, e-coating is essential for corrosion protection and system reliability, especially when paired with a UV-resistant topcoat.

Reference to Previous Standard (ISO 12944:1998)

For projects or specifications still referencing the older ISO 12944:1998 standard, the updated classification aligns as follows:

|

OLD CLASSIFICATION |

UPDATED CLASSIFICATION (2018) |

|

C5-I (Industrial) |

Merged into C5 |

|

C5-M (Marine) |

Merged into C5 |

|

– |

CX introduced for offshore & extreme |

Kaltra recommends e-coating for all heat exchangers intended for environments rated C4, C5, or CX. Our cathodic epoxy electrocoating process ensures reliable long-term protection against corrosion, even in the most aggressive atmospheres.

Precision-Controlled E-Coating for Long-Term Corrosion Protection

The effectiveness of e-coating in protecting microchannel coils depends heavily on precise control of deposition parameters. Critical factors such as immersion time, bath voltage, and epoxy formulation quality directly influence coating uniformity and adhesion. Insufficient deposition can lead to weak coverage and reduced corrosion resistance. Customers frequently encounter inadequate e-coating performance when the application process is simplified, resulting in incomplete coverage and reduced protective properties.

At Kaltra, the e-coating process is carefully engineered to achieve complete and consistent coverage across the entire coil surface.

A fully controlled e-coating process guarantees:

- Precisely regulated immersion time and voltage, ensuring complete and uniform epoxy coverage across the entire coil surface.

- High-performance epoxy formulations that deliver consistent film thickness, strong adhesion, and lasting protection.

- Carefully calibrated post-curing, enhancing coating hardness and providing long-term resistance to chemicals and environmental degradation.

This results in superior corrosion protection, especially in aggressive environments such as coastal, industrial, or polluted air zones—delivering longer service life and reduced maintenance for our customers.

Learn More

For more detailed information on e-coating chemical resistance, process specifications, and performance testing, please refer to our Protective Coatings brochure.