WATER COILS FOR COOLING AND HEATING

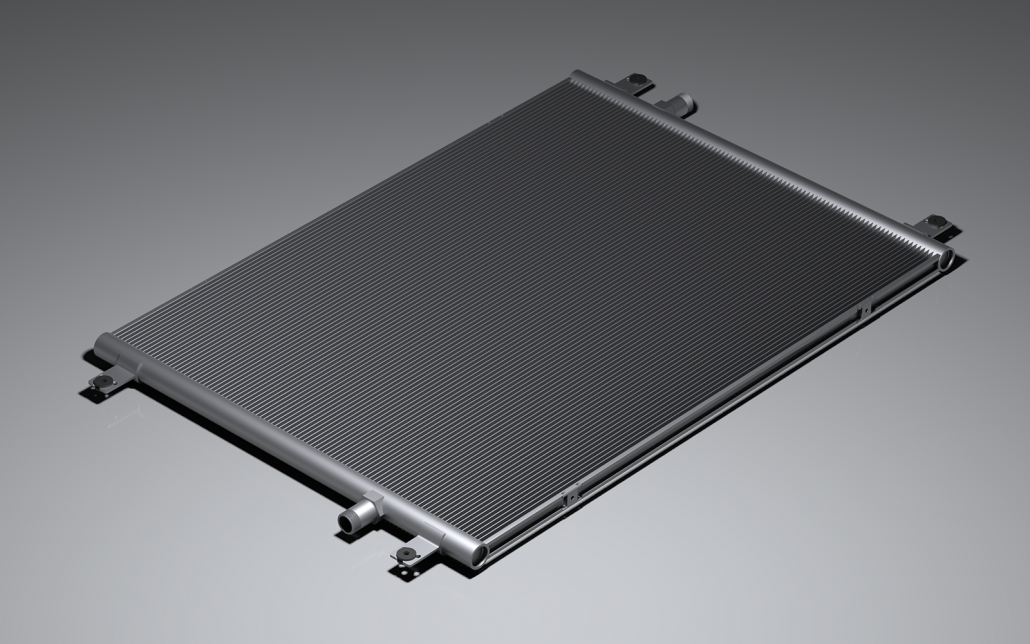

Microchannel heat exchangers can be configured for single-phase air-to-fluid heat transfer applications, efficiently cooling or heating various media, including water, glycol mixtures, oils, and specialized fluids.

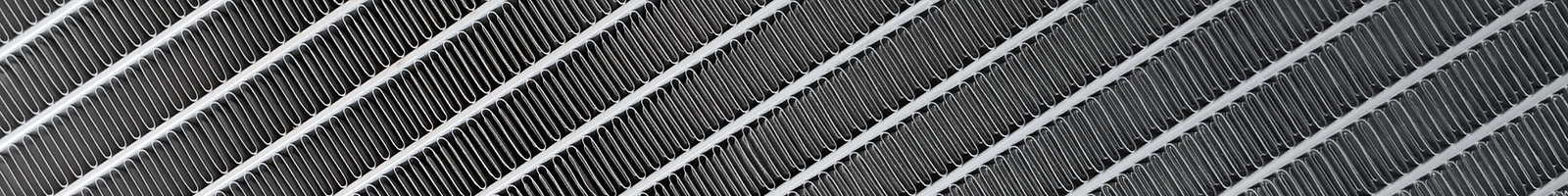

Fluid coils inherit all the advantages of microchannel coil technology, including high heat transfer rates, an improved capacity-to-size ratio, reduced fan power consumption, and lower overall weight. Additionally, microchannel water coils provide outstanding corrosion resistance, ensuring a longer service life.

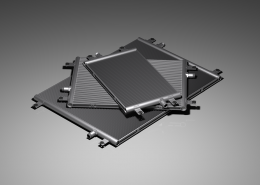

Kaltra’s microchannel water coils stand out for their exceptional performance—thanks to the optimized geometry of tube ports—and robustness, achieved through increased wall thickness and advanced protective coatings applied to both the outer and inner coil surfaces. Customers can choose from designs featuring either vertical or horizontal tube arrangements.