Superhydrophobic microchannel heat exchanger for heat pump performance enhancement

Amid the global shift towards carbon neutrality, air-source heat pumps (ASHP) have emerged as efficient and environmentally beneficial to traditional boilers, attracting substantial attention in recent years. Contrary to the cooling process, where the condenser is inside, the heating process uses an indoor condenser and an outdoor evaporator in ASHPs.

One of the main challenges for ASHPs is that moisture in outdoor air often results in frost accumulation on the evaporator surface, creating a layer that increases thermal resistance and lowers the heat transfer coefficient. Therefore, defrosting techniques for heat pump systems have become a key research area in the industry.

Passive Defrosting Techniques

Defrosting techniques can be classified into active and passive methods, where active methods include compressor shutdown defrosting, hot-water-spraying defrosting, electric heating defrosting, reverse-cycle defrosting, hot-gas bypass defrosting, and more, while passive methods typically involve modification of the heat exchanger surface with antifreeze and superhydrophobic coatings that enhance drainage efficiency and reduce frost adhesion. Passive defrosting methods also include particular circuiting of heat exchangers for shift operation or installing dehumidification coils in front of evaporators. It must be noted that passive defrosting techniques exhibit slower defrost rates but, in many cases, do not require additional hardware or extra energy. This has made passive defrosting a prominent area of research in recent years. Recently, Kaltra conducted an analysis of superhydrophobic surface treatment applied to a louvered-fin microchannel heat exchanger (MCHE) to evaluate its impact on moisture drainage.

Superhydrophobic Coating

During frosting, water vapor from the humid air passes through the evaporator and can either condense and freeze or deposit as ice. The outcome is reliant on the temperature of the evaporator’s surface and the humidity of the air entering it. With a superhydrophobic evaporator surface, water droplets coalesce and jump off the surface before they have a chance to freeze, thus increasing the condensate removal rate and delaying frosting. Superhydrophobic surfaces reduce adhesion force between frost and surfaces, improving condensate drainage and reducing surface water retention.

Trial on MCHE With Superhydrophobic Coating

During our tests, we initially configured the control parameters to attain a high-side pressure that maximized the cycle efficiency. As the experiments progressed, we monitored the air-side pressure drop across the outdoor evaporator and used it as a defrost criterion. Once the air-side pressure drop went beyond the maximum allowable limit, we initiated the defrost cycle by turning off the compressor. We kept the compressor off until all the frost was removed from the heat exchanger.

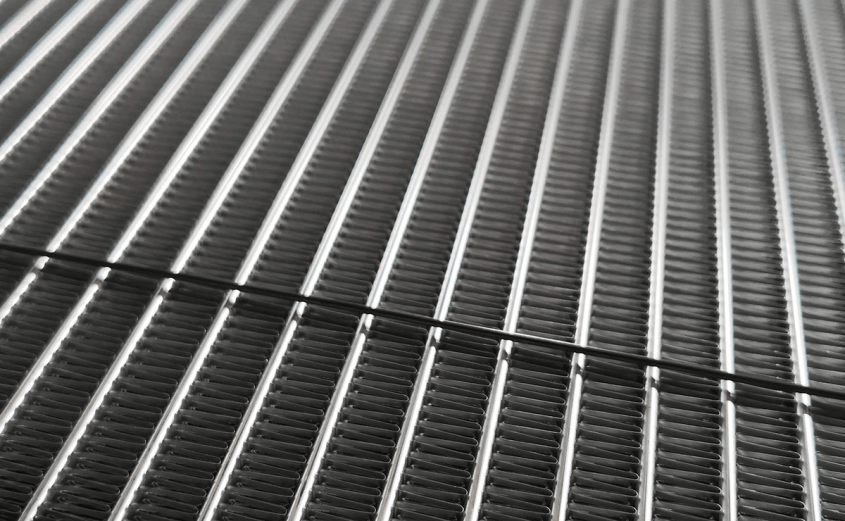

The microchannel evaporator coil used in tests was vertical-oriented, with manifolds on top and bottom and vertical MPE tubes, since such design ensures better frosting/defrosting performance owing to its superior water drainage along vertical fins and tubes.

To evaluate the defrosting effect of the superhydrophobic coating, an experimental setup included coated and bare heat exchangers located in an environmental chamber. These microchannel heat exchangers simulated the working conditions of the evaporators in the heat pumps and were supplied with low-temperature fluid.

In the experiment, the inlet temperature, humidity, and velocity of the air were controlled at 10°C, 75%, and 1.5 m/s, respectively. Fluid inlet temperature was kept at -5°C.

After 30 minutes of operating, frost accumulation appeared on both heat exchangers, with and without superhydrophobic coating. The microchannel heat exchanger with a superhydrophobic coating had a frost thickness measurement of approximately 0.4mm, while the one without the coating had a frost thickness of about 0.8mm. This indicates that the addition of the superhydrophobic coating to the fin surface helps to defrost the exchanger. When the frost thickness reaches 0.8 mm, it blocks the flow area of the microchannel heat exchanger, leading to a rapid decrease in the air-side heat transfer coefficient and pressure drop.

Figure 1: Heat transfer degradation with frost grow

Figure 2: Airside pressure drop increase with frost grow

The degradation of the heat transfer coefficient becomes pronounced when the frost thickness surpasses 0.4 mm, curtailing the heating capacity and thereby significantly decreasing the COP. The microchannel heat exchanger with superhydrophobic coating demonstrates less frost accumulation than the one without, enhancing the heat transfer coefficient and improving the cycle performance of heat pumps under cold operating conditions.

In our tests, the increase in frost thickness from 0 to 0.8mm led to a decline in heating capacity 2.25 times. When the frost thickness exceeds 0.4mm, heating capacity and compression power decrease steeply. Thus, frost thickness should be restrained to 0.4mm during operation to maintain adequate heating capacity.

Figure 3: Frost thickness vs. capacity

***

The study demonstrates that surfaces with superhydrophobic properties can significantly delay frost formation and improve the performance of heat pumps. Although the benefit diminishes as the system cycles between frosting and passive defrosting, the higher heat transfer rates and COPs are maintained long enough for most heating applications.

Superhydrophobic vs. Hydrophilic Coating

We also conducted periodic frost-defrost experiments on heat exchangers coated with hydrophilic and superhydrophobic coatings. We have found that evaporators with superhydrophobic coating have shorter defrosting duration by 10% compared to one with hydrophilic coating. Both hydrophilic and superhydrophobic samples exhibit satisfactory cyclic repeatability with no noticeable capacity attenuation. After defrosting cycles, the residual water of the superhydrophobic specimen was 20% less than that of the hydrophilic one.