New screw chillers: 24/7 service under toughest operating conditions

Dangerously high summer temperatures, highlands above 1800 meters, sandstorms and year-round operations – are conditions under which the new cooling system that includes two Kaltra chillers should reliable function, supplying chilled water to the pharmaceutical plant and product storage area in Tehran.

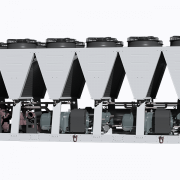

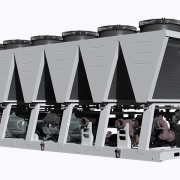

Kaltra has experience installing numerous chilled water systems in such harsh conditions and equipment to cope with them – equipped with high-temperature kits, protection and shielding features. The latest generation of air-cooled chillers, Lightstream Screw II units capable of operating under ambient temperatures of up to 54 Celsius, were selected for the plant. Configuration with high air temperature kits, AC fans to withstand high exhaust temperatures, condenser coil guards, high-grade pipework and evaporator insulation, compressor overheating control, and mechanical cooling for electrical cabinet and controls ensure stable work, as well as environmental sustainability with lower GWP refrigerant R513a selected for the system.

The chilled water plant comprises two chillers, delivering 1100kW cooling. Integrated sequence management enables coordinated system operation that minimizes energy use and balances load between units’ compressors.

“One of the challenges we faced was voltage fluctuations and flickers. We added automatic switches to all loads for protection, including fans, compressors, and other motors. Soft starters were installed on both chillers to mitigate their impact on the plant’s power distribution grid,” says Andreas Moeller, Kaltra’s engineer in chief. “Novel condenser design of Lightstream chillers ensures subcooling high enough for efficient operation of the EEV while condensing pressure remains relatively low, eliminating strain on the compressors running at very high ambient,” he added.

The cooling plant has become operational this spring and already runs under peak seasonal ambient at 100% loads. A special system maintenance plan for challenging operating environments has been put in place to guarantee reliability and full-load performance of the system.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 253 421 07 or visit www.kaltra.com