1. WATER DISTRIBUTION

Water is distributed over the length of evaporative pads by spraying over the evaporative media through the orifices located in the header pipe. Each pad row integrated with water redistributor, which evenly feeds underlying pads with water. The system operates with tap water.

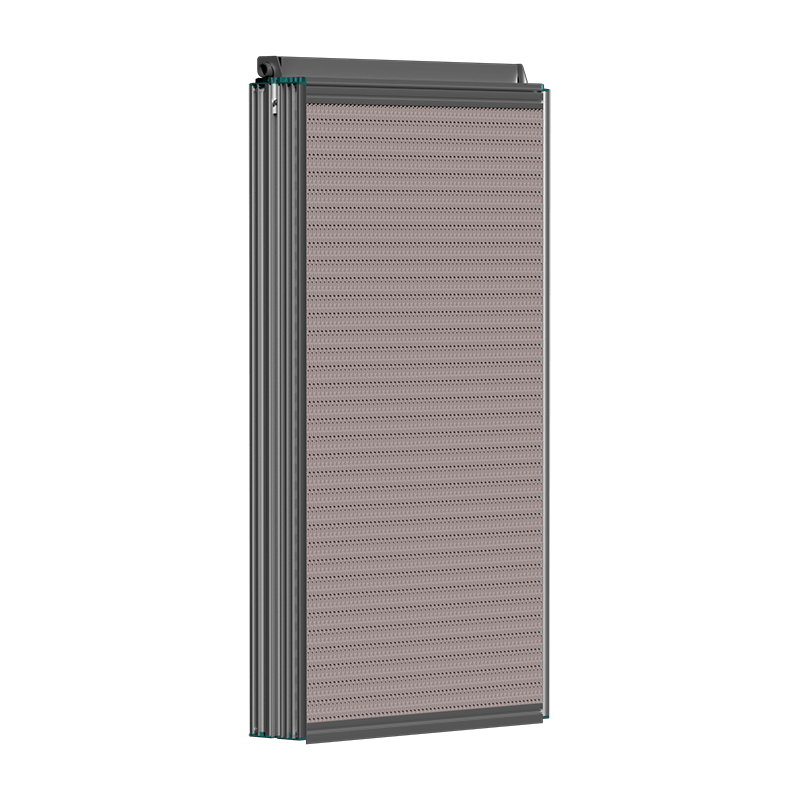

2. EVAPORATIVE MEDIA

The evaporative media made of water retaining finned aluminium plates designed for maximum saturation efficiency, which reaches 90% at the air velocities of up to 2m/s. The internal geometry of evaporative media facilitates minor air pressure drops while the special fin coating retains the cleanliness of the media. The system doesn’t require droplet eliminators for the air velocities of up to 3m/s and can be installed at an angle of up to 30° to vertical. Intake air flows through the wetted pads and cools down due to the adiabatic evaporation process.

3. WATER DRAINAGE

The system includes a drip tray to collect water for further reuse in an evaporation process. The drip tray is connected to the pumping station, which analyzes returning water and performs its treatment, if necessary.

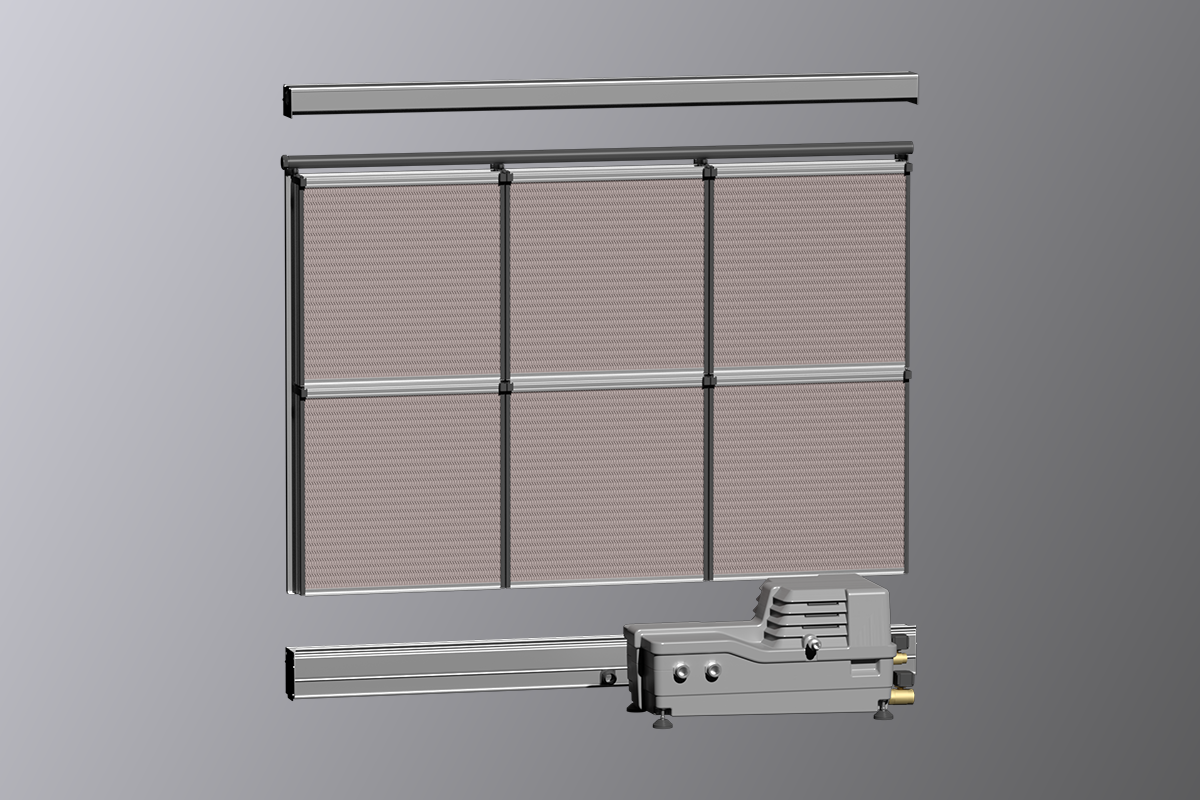

4. PUMPING STATION

In order to achieve maximum efficiency with minimal water consumption, E•VAP™ pre-cooling system can be equipped with a pumping station which includes circulation pump, water treatment module, and control system with state-of-the-art algorithms that monitor ambient conditions and determine operation modes, ensuring the E•VAP™ system is active only when necessary. The fully automated water management system continuously monitors the water quality, drains the system, and refreshes the water when mineral levels reach maximum allowable values.

5. FRAMING

The lightweight, self-supporting aluminium frame has been designed to connect evaporative pads in series horizontally and stack them vertically. While each media pad is detachable, the entire E•VAP™ assembly, in turn, can be disengaged from the cooling unit. E•VAP™ system is also suitable for retrofit applications due to its flexibility, easy installation, and low airside pressure drops. Retrofitting the cooling units with E•VAP™ results in significant electricity savings of up to 30% and even higher.