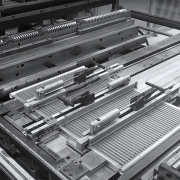

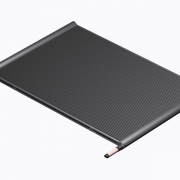

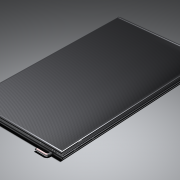

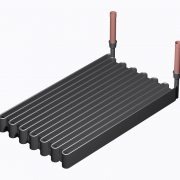

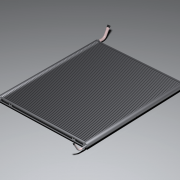

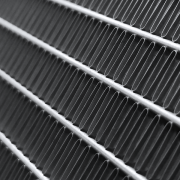

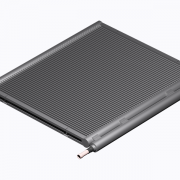

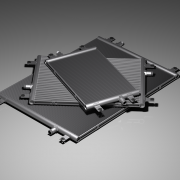

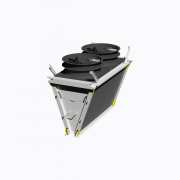

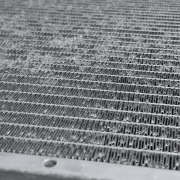

Kaltra confirms superior frosting performance of reversible microchannel coils through extensive testing

Kaltra has completed a comprehensive testing program validating the performance and operational robustness of its reversible microchannel heat exchanger coils across a wide range of operating conditions. The results confirm the technology’s suitability for demanding heat pump applications and reinforce its position as the most innovative solution within Kaltra’s microchannel heat exchanger (MCHE) portfolio.