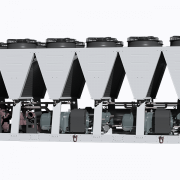

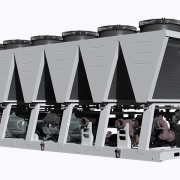

Free cooling Lightstream Turbo II now available on R1234ze

Last month, Kaltra added a free cooling version to its Lightstream Turbo II R1234ze range, targeting hyperscale data centers and critical IT infrastructures.

Turbocor, two-stage, variable speed, oil-free centrifugal compressors offer the highest efficiency rates, quiet operation, and low inrush currents.

Integrated free cooling management logic, which makes the most of the high efficiency of the Turbocor compressor at partial loads, allows 10 to 20% savings in energy consumption. Ancillary to this, a low-lift refrigerant pump allows to keep compressor motor cooled, enabling lower compression ratios and thus increasing compressor efficiency.

New units feature twin-slab microchannel condenser coils offering a high degree of subcooling and resultant increased heat rejection capacity and compressor COP. Free cooling coils are also microchannel, with improved heat transfer, which provides a higher percentage of full free cooling over the course of a year. All coils are made of long-life aluminum alloys and, optionally, can be supplied with an epoxy electrophoretic coating that drastically increases the coil’s service life. Large 910mm EC axial fans with sound-reducing diffusers are installed as standard to compensate for added air resistance induced by free cooling coils.

R1234ze, with a global warming potential (GWP) of just 1, has negligible greenhouse effect in comparison to traditional HFC refrigerants.

The range includes models with cooling capacity up to 1800kW.

The units work with return water temperatures of up to 40°C and deltas up to 20°C, with full free cooling achievable at 13.0°C ambient.

Upon request, Lightstream Turbo II can be supplied with:

- Fast restart system with uninterruptible power supply (UPS)

- Dual power supply with an automatic transfer switch

- Active harmonic filters

- Refrigerant leak detector

- Hydronic module

- Energy metering system

New chillers are available in non-glycol configurations, with an intermediate heat exchanger that isolates glycol flow in a free cooling system from plant water.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 384 333 48 or visit www.kaltra.com