Kaltra raises the bar for industrial dry coolers

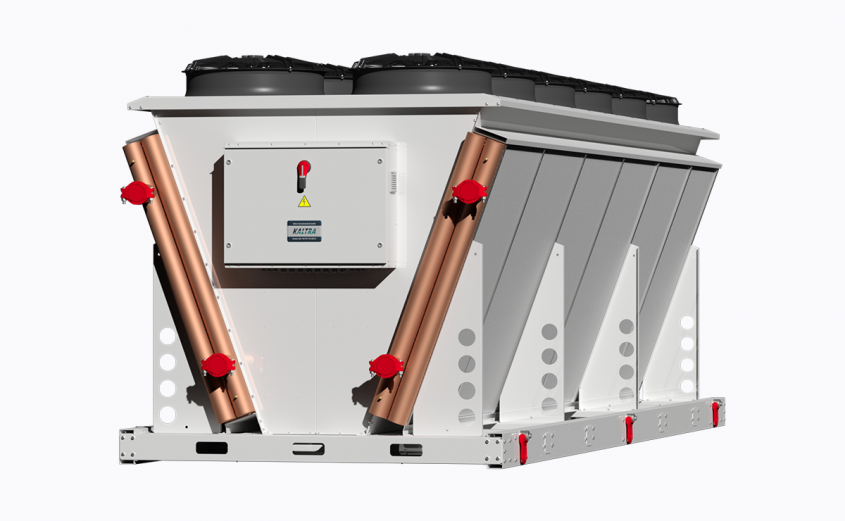

Kaltra has extended its range of high-capacity dry coolers with Mistral series units in a V-shaped configuration, up to 2000kW in the air-cooled version and as high as up to 3000kW with the adiabatic: a total of about 500 models.

While differing in the range of applications, new Mistral dry coolers are built around finned tube heat exchangers with improved heat transfer performance. Inner-grooved copper tubes of a small diameter contribute to a cooling density of 75kW/m² and higher. At the same time, airside fins with unique profiles create a low pressure drop, enabling lower fan energy use and maintain moderate noise levels.

For sensitive applications, we made available heat exchangers with stainless steel pipes and a selection of fin materials: aluminum, aluminum-magnesium alloys, and copper.

Mistral dry coolers have been developed for cooling applications in the oil&gas, chemical, petrochemical, power generation, and food processing industries. Corrosion-resistant, robust, and easily serviceable design contributes to long operating life even in harsh environmental conditions.

Customers can choose from AC- or EC-driven fans, single or multiple fluid circuit configuration, and various anti-corrosion treatments for cooling coils. Numerous options allow further tailoring of Mistral dry coolers to user needs.

Adiabatic version

Dry coolers can be equipped with an adiabatic pre-cooling system based on non-organic evaporative pads made from aluminum, making Mistral units a legionella-free solution. Pre-cooling system can be fed by tap water and allow water recirculation by optional pumping and water treatment unit.

***

Selection Guide for updated Mistral-W dry cooler range can be downloaded here.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 89 943 99-8-66 or visit www.kaltra.com