Dry coolers vs. wet cooling towers

Working Principle

Cooling towers are heat-transfer devices that are used to reject heat loads to the atmosphere. Cooling towers are used to cool circulating water in a wide variety of applications such as process cooling and HVAC systems.

Cooling towers extract heat to the atmosphere through the cooling of a water stream to a lower temperature. There are two main types of cooling towers:

- Open-circuit cooling towers (also referred to as wet cooling towers), where process water directly contacts with the ambient air;

- Closed-circuit cooling towers, or dry coolers, involve no direct contact between the ambient air and the fluid being cooled.

Both types serve the same purpose but cool the water in different ways.

Wet cooling tower relies on the latent heat of water evaporation to exchange heat with the air stream passing through it, and able to bring the process water temperature down below the ambient temperature to a certain degree above the dew point (approach temperature). Opposed to it, dry cooler only brings the water temperature down to the ambient, but additional cooling can be achieved by adiabatic pre-cooling of the inlet air. Wet cooling towers work efficiently in hot and dry climates, but as the ambient air becomes humid, the performance of wet cooling towers fall. Conversely, dry cooler performance is not affected by air humidity but relies on the air temperature.

System Design

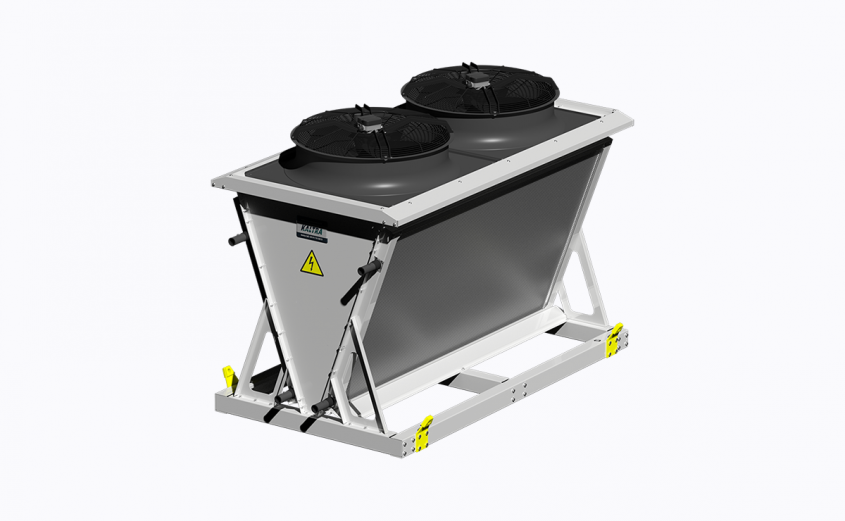

Dry Coolers

Dry coolers feature a straightforward and robust design which includes a heat exchanger (typically finned tube or microchannel coils) and fans which direct the airstream through the heat exchanger to cool the water or glycol solution passed through it. Dry coolers are mostly available in horizontal or vertical airflow arrangement. Heat rejection capacity typically ranges up to 1MW, although large-capacity dry coolers are also available on the market.

Modern designs may include pre-cooling systems, either adiabatic spray or wetted pads. Evaporative pre-cooling allows cooling the process fluid below dry bulb temperature.

Wet Cooling Towers

The structure of a wet cooling tower is way more sophisticated. It includes nozzles to spray hot water homogeneously onto the heat exchanging media (also referred to as fill or wet deck), fans which direct ambient air throughout the cooling tower, drift eliminators which prevent water droplets from discharging with the air, and collection basin for the cooled water. The air flows from the bottom of the tower (counterflow-type tower) or perpendicular to the direction of water flow (crossflow-type tower).

The most common types of heat exchanging media are film fill and splash fill. Film fill is a set of textured sheets with the large surface area on which the water spreads and forms a thin film in contact with the airflow. This guarantees a high rate of heat exchange between water and air. Splash fill is a multilayered structure which forms small droplets to increase contact between air and water, also resulting in a high heat transfer rate. Selection of the fill media shall be based on water quality: film fill is ideal for clean water, while splash fill is suitable for poor-quality or dirty water with high solids content.

Special solutions are available for reducing the risk of bacterial growth, e.g., anti-legionella fill media which works by disrupting the metabolic process of microorganisms and interrupting bacterias’ ability to grow and reproduce.

Drift eliminators are a vital component of maintaining the efficiency of a cooling tower and minimizing the loss of water. The structure of a drift eliminator provides multiple deflections of the air stream, thus forcing water droplets which are carried away with the airflow to deposit on the surface of eliminator and drip down to the collection basin.

Pros and Cons

Wet (open-circuit) cooling towers more suitable for large industrial facilities that require cooling of vast volumes of water:

Pros:

- Ability to cool down process water below dry bulb temperature;

- Reliable operation in hot ambient conditions;

- High cooling capacity per unit.

Cons:

- High equipment and installation costs;

- High operating costs which include frequent water treatment/refill, maintenance of system components, electricity costs;

- Relatively high water consumption due to evaporation;

- Formation of rust along the pipework;

- Growth of bacteria, including legionella.

Dry coolers are particularly suited for small-to-medium industrial and commercial applications and free cooling systems:

Pros:

- Low initial, operating, maintenance costs;

- Ability to work in any climate conditions, from hot and humid to extreme cold;

- Wide variety of unit designs that provides the possibility to suit it for nearly all environments and applications;

- Minimal system fouling and process water contamination.

- No water loss.

Cons:

- Cannot cool the process water below dry bulb temperature (without adiabatic pre-cooling);

- Relatively low capacity per unit.

As closed-circuit systems, dry coolers deliver several benefits compared to wet cooling towers, including lower initial costs and maintenance, improved system reliability, and increased uptime. Being equipped with evaporative pre-cooling, dry coolers offer the efficiency which is, as for wet-type cooling towers, only limited by wet bulb temperature.

In light of the above, the most significant factor in the choice between open-circuit cooling tower and dry cooler remains the system capacity. Continuous introduction of new efficient technologies such as microchannel heat exchangers, EC fans, intelligent controls, and others let consider dry coolers as an effective part of new environmental friendly thermal systems.