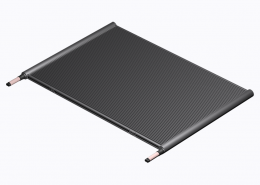

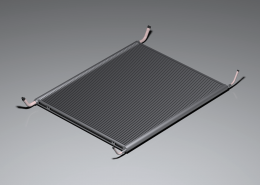

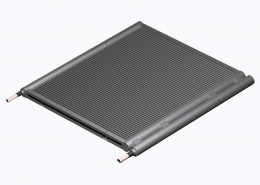

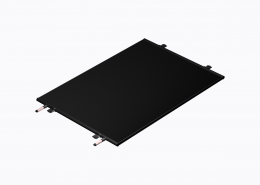

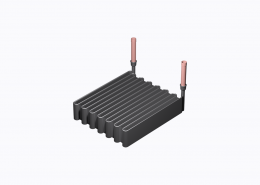

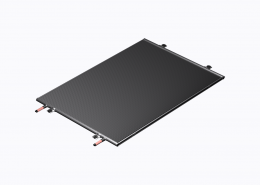

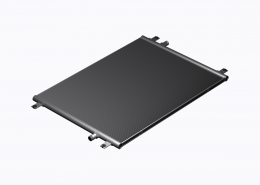

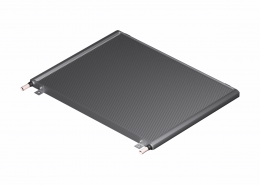

HEAT EXCHANGERS ADOPTED FOR EVAPORATOR APPLICATIONS

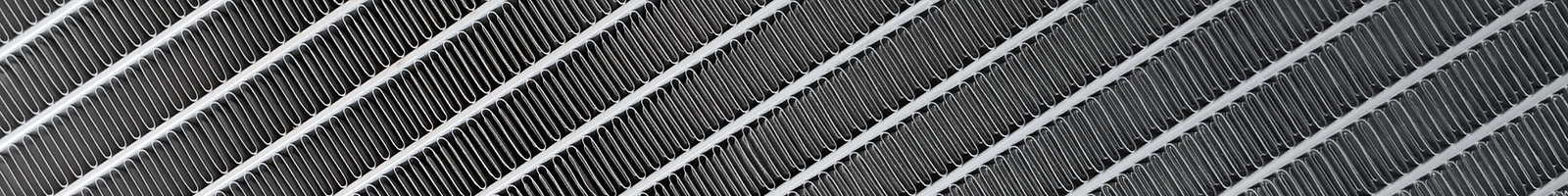

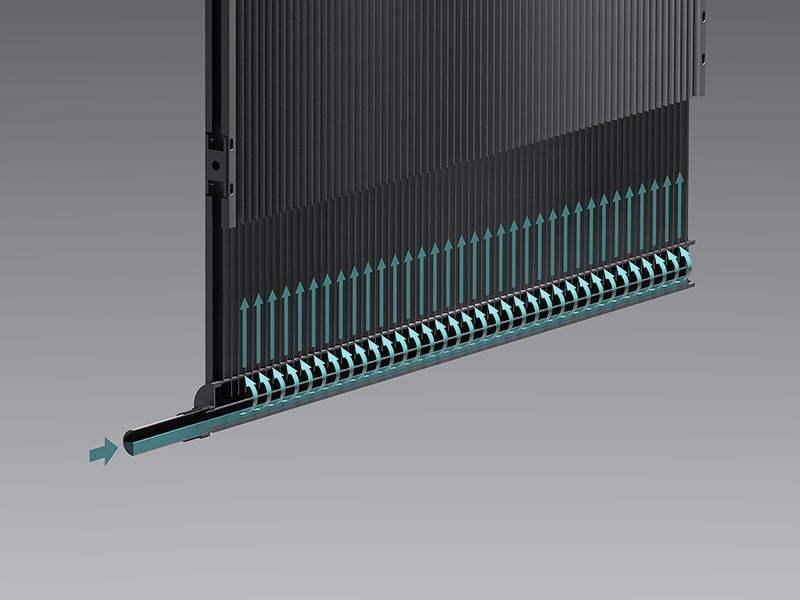

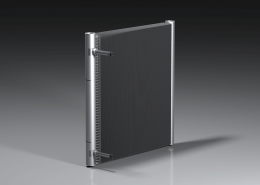

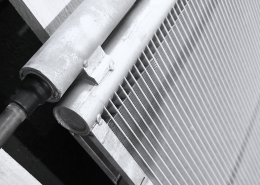

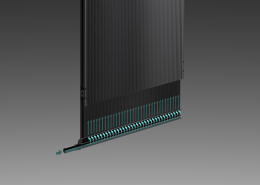

Kaltra’s microchannel evaporators utilize advanced techniques to ensure uniform refrigerant distribution across microchannel tubes, effectively minimizing superheated regions. This results in optimal thermal performance across a wide range of operating conditions and loads, addressing key design challenges. With the capability of operating in reverse acting as condensers, our microchannel evaporators are ideally suited for air-source heat pumps.

By relying on our microchannel evaporators, customers enjoy the full spectrum of benefits offered by microchannel technology, including superior heat transfer rates, lower refrigerant charge, reduced fan power consumption, and a more compact, lightweight design—ensuring optimal efficiency across both full and part load conditions.