Kaltra deploys new aluminum alloy for microchannel heat exchangers

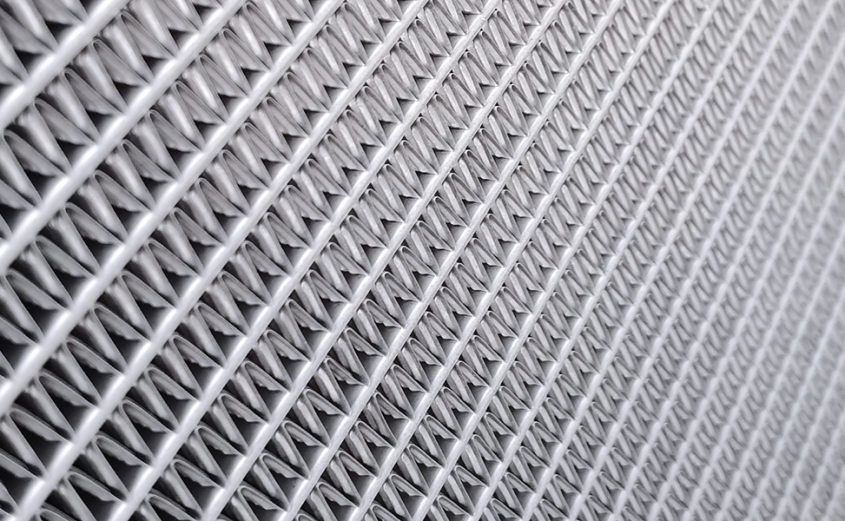

Kaltra completed the pilot study for a new, highly corrosion-resistant aluminum alloy, AA3F05, temper H112, to be used in its microchannel heat exchangers. SWAAT (Sea Water Acetic Acid Test as per ASTM G85 Annex A3) tests performed during the deployment phase demonstrated that AA3F05’s lifespan is more than double that of the currently used HA9153 alloy.

Manganese-riched AA3F05 with a protective zinc top layer ensures up to 6000 hours of exposure to synthetic sea salt and humidity at high temperatures, making possible long service life for heat exchangers in the harshest air conditions.

Alloy AA3F05 is available for multiport tubes with widths from 12 to 36mm and pressure rates of 32 and 45 bar, covering the full range of coil nomenclature and suitable refrigerants.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 384 333 48 or visit www.kaltra.com