AIR-COOLED CHILLERS

Lightstream Scroll II

Chillers with multi-refrigerant scroll compressors to provide environmentally safe, energy-efficient cooling in wide operation conditions

Applications: Air conditioning • Process cooling • Commercial

AIR-COOLED CHILLERS

Chillers with multi-refrigerant scroll compressors to provide environmentally safe, energy-efficient cooling in wide operation conditions

Applications: Air conditioning • Process cooling • Commercial

For numerous variety of process cooling and comfort applications, Lightstream Scroll II air-cooled chiller provides superb efficiency and performance and enables customers to meet regulatory obligations and sustainability goals by running on lower GWP refrigerants R452b, R454b, and R32. Numerous options include integral free cooling, hydronic packages, low-sound designs, coil coatings, and other accessories to fit a variety of customer needs.

Compared to the previous generation of scroll chillers, energy efficiency lifted by 15%, while the capacity range extended to 250 to 1100kW cooling. Multiple scroll compressor technology combined with state-of-the-art compressor control algorithms enables efficient chiller operation at both low partial and full loads and provides reliability, redundancy, and serviceability.

Advanced technologies adopted in Lightstream Scroll II design attach this chiller advantages more typical of large, expensive chillers: high energy savings potential, environmental friendliness, and versatility in applications.

All units are compliant with all applicable EU Ecodesign Regulations (Tier-2) under the ErP framework Directive 2009/125/EC.

MULTI-COMPRESSOR, MANIFOLDED DESIGN

Lightstream Scroll II chillers feature the latest multi-refrigerant scroll compressor technology with Intermediate Discharge Valve (IDV) to enhance seasonal part-load cooling efficiency. The benefits of this compressor range include support for refrigerants R452b, R454b, R32, and R410a, a variety of manifold configurations, and extended operating maps to fit a wide range of applications, both reversible and cooling only.

Multi-compressor technology, being combined with IDVs, gives these chillers excellent efficiency and thermal stability under partial load conditions, starting from as low as 10%.

Lightstream Scroll II chillers running on refrigerants R452b, R454b, or R32 possess some of the lowest Global Warming Potential for scroll systems available today.

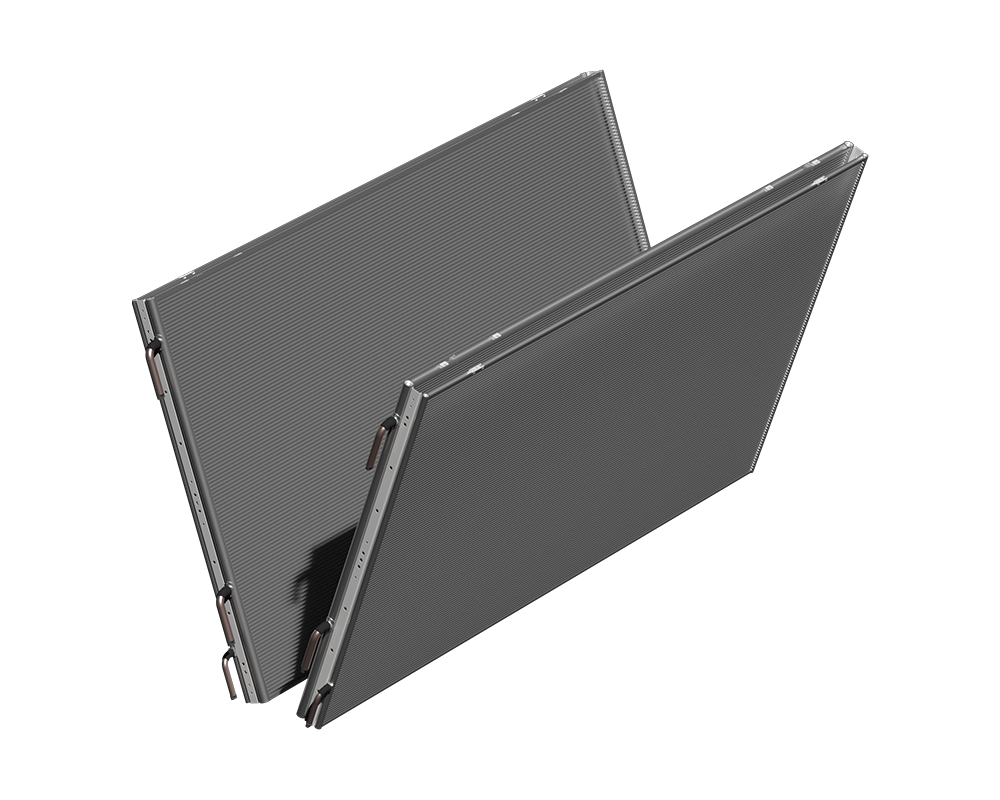

SHELL-AND-TUBE HEAT EXCHANGERS

Evaporators for Lightstream Scroll II chillers were designed for close temperature approach and feature tube bundle arrangement optimized for low refrigerant charges, maximum efficiency, and for compressors to operate at higher saturated evaporation temperatures, generating more cooling capacity with equal power input. Designed in-house by Kaltra heat transfer experts, Lightstream’s evaporators are ones of state-of-the-art technology, with deep optimization for use with low-GWP refrigerants.

LATEST GENERATION EC-DRIVEN FANS

As standard, Lightstream Scroll II chillers are supplied with ErP 2020 compliant, EC-driven, aerodynamically optimized axial fans in lightweight housings and with guide vanes to reduce sound emissions and maximize airflow. Impellers with profiled blade geometry and winglets harmonized with the fan motor contribute to the highest energy efficiency.

Fans feature monitoring functionally via Modbus, integrated thermal overload and locked-motor protection, and low-temperature bearings ensure smooth and trouble-free fan operation under low ambient conditions.

Significant refrigerant charge reduction by up to 50% achieved for Lightstream Scroll II with the use of microchannel condenser coils with multiport tubes having orifices of sub-millimeter diameter, which dramatically decrease the internal volume of the coil.

Brazed joints provide low contact resistance and, in combination with large heat transfer surfaces, enable high heat transfer characteristics for Lightstream Scroll II chillers.

Improved corrosion resistance is another advantage inherent in microchannel coil technology. Heat exchanger components are made of long-life aluminum alloys with a zinc arc spray finish. Additional corrosion protection required for installations in highly polluted zones or coastal applications can be achieved with epoxy electrophoretic or trivalent chromium process coatings available optionally.

The control system is based on a high-speed controller equipped with the latest microprocessor. The control software has been developed with a focus on energy-efficient operation for multiple scroll compressor air-cooled chillers. To achieve the best possible efficiency for multi-compressor chillers, compressor management software constantly monitors the actual cooling demand and selects compressors to run.

Giving complete control over the system for the plant operator, the chiller software manages and optimizes the chiller’s performance according to cooling demand and ambient conditions, generates safety and security alarms, supports interlinked, coordinated operation of multiple units, provides diagnostics and run statistics, and allow easy integration with any BMS protocols.

LOWER GWP REFRIGERANTS

The proposed phase-down of HFC refrigerants has prompted an assessment of alternative fluids for a wide range of applications, including medium-temperature air-cooled chillers. In parallel with R410a, we offer a selection of lower GWP gases for Lightstream Scroll II: R452b, R32, and R454b.

With low-GWP refrigerants and low-volume microchannel condensers, Lightstream Scroll II is an undoubted leader in environmental sustainability while achieving the best energy performance levels in applications.

Feature-rich in standard, Lightstream Scroll II is highly configurable for different customer requirements and facility layout needs – thanks to numerous available accessories and options.

Free cooling version provides low energy cooling and enables significant savings at low-ambient conditions. In mild temperature conditions, when the ambient temperature drops below the return water temperature, the free cooling system operates in parallel with mechanical cooling, maximizing energy savings. Through the use of microchannel cooling coils, the air temperature at which the free cooling system provides 100% cooling demand is higher by 3°C to 5°C compared to heat exchangers of other types. The flow through the cooling coils is controlled through a 3-way mixing valve managed by the chiller software.

|

Capacity [kW] |

250 … 1100 |

|---|---|

|

Design |

AIR-COOLED |

|

Compressors |

SCROLL |

|

Refrigerant |

R410A/R32/R452b/R454b |

|

Energy efficiency (EER) |

UP TO 3.56 |

|

Seasonal efficiency (ESEER) |

UP TO 5.12 |

|

Fan motors |

EC(STANDARD)/AC |

|

Condensers |

MCHE |

|

Evaporators |

SHELL-AND-TUBE |

|

Evaporation control |

EEV |

|

Refrigeration circuits |

SINGLE/MULTIPLE |

|

Warranty |

3 YEARS |