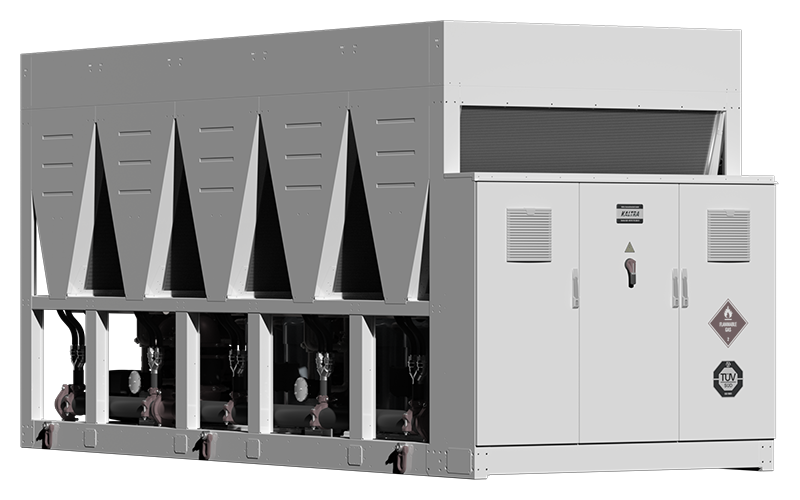

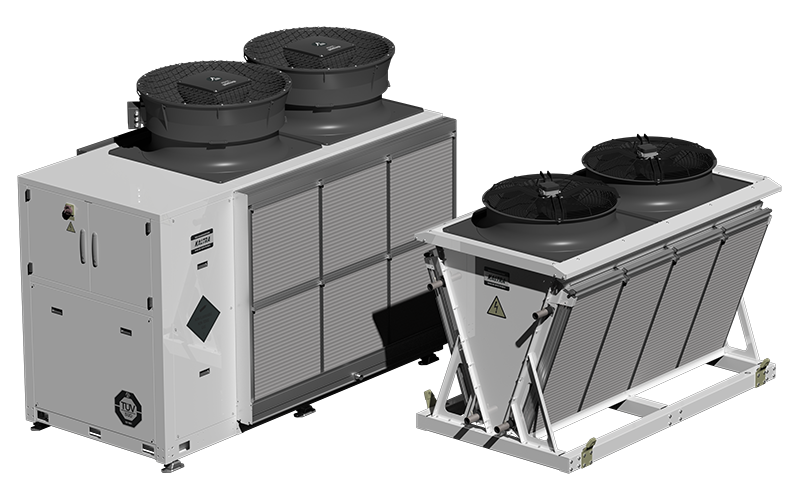

ADVANCED COOLING TECHNOLOGIES

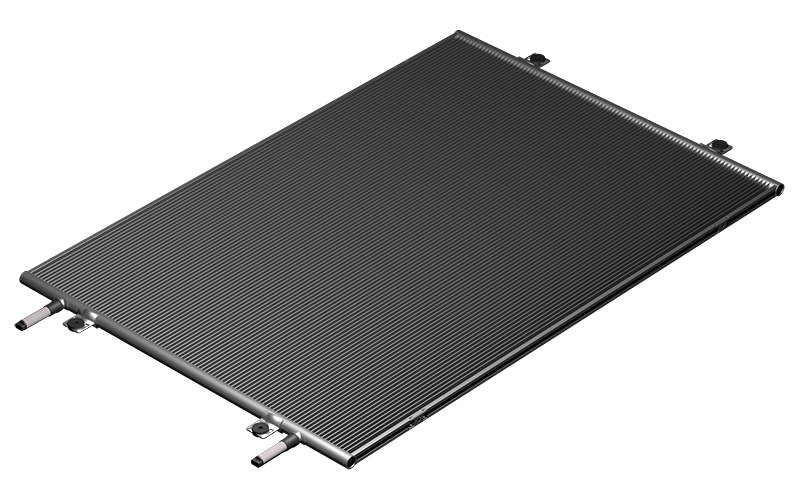

Kaltra is committed to continuous improvements in its equipment performance and efficiency, and to increase the development of environmentally-safe cooling and refrigeration systems. To achieve these goals, Kaltra invests heavily in its research and development facilities and works closely with several research institutions and laboratories to create the most advanced products based on modern cooling technologies.