Microchannel evaporators: a study for efficiency optimization

Microchannel evaporators provide several advantages over traditional coils, the most important of which are high heat transfer rates and low internal volume, and have been widely studied with a focus on refrigerant distribution and condensate behavior. The present study reviews the impacts of refrigerant charge quantity and arrangement of refrigerant inlets and outlets on evaporator performance.

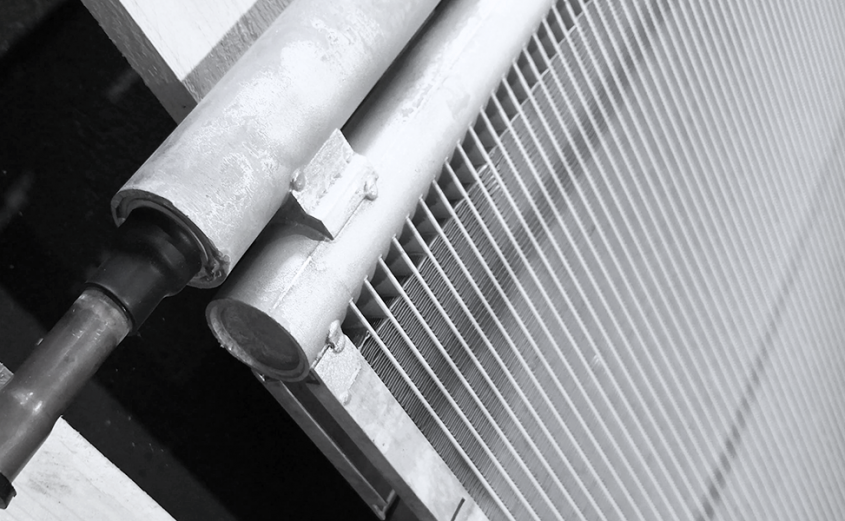

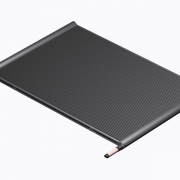

In our experimental study, we evaluated microchannel evaporators with different R134a charges and with three refrigerant inlets: same-side (“S”), where inlet and outlet connections are located at the same side of the coil; opposite-side (“O”), and with inlet connection located in the center of the inlet manifold (“C”). Additionally, for comparison reason, we added a setup with equivalent finned-tube coil.

We evaluated the following parameters:

- Coil surface temperatures

- Flow distribution between microchannel tubes

- Cooling capacities

- Energy efficiency ratios

The evaporator design of an overall size of 400x600mm included 32-mm inlet and outlet manifolds with 40 vertically-oriented microchannel tubes in between. The optimum charge quantity was predicted in the range of 1350-1400g.

Results

Evaporator with oppositely-located refrigerant inlet and outlet demonstrated 11% higher capacity versus the same-side inlet/outlet variant and outran the design with a central inlet by 3.5% (Figure 1).

Figure 1: Evaporator capacity vs. refrigerant charge

The same pattern was observed in measuring system efficiency, except in the case of overcharged systems: an evaporator with a central refrigerant inlet displayed slightly better efficiency than one with same-side connections (Figure 2). With the optimum charge, the coil with opposite connections outperforms other designs by 7%.

Figure 2: Evaporator efficiency vs. refrigerant charge

Surface temperature difference (measured at the bottom and top of each tube) fluctuated in the 0,8°C range among tubes for evaporators with opposite and central inlets, while for same-side evaporator inlet, the delta was as high as 2,4°C. In all cases, no superheated regions were observed.

Distribution of refrigerant mixture between tubes was about even for “O”-design with opposite inlet and outlet. For the same-side “S” design, the feed was insufficient for microchannel tubes furthest from the inlet, while the design with refrigerant inlet in the center (“C”) demonstrated inadequate feeding to the tubes located at both sides.

Conclusion

Correct and efficient operation of microchannel evaporators depends on many aspects like the use of refrigerant distributor, accurate sizing, ensuring free condensate drainage, and more. Besides, charge quantity and arrangement of refrigerant inlet and outlet should be in clear focus due to their strong impact on coil performance:

- Correct refrigerant charge quantity is crucial as it affects evaporator efficiency and cooling capacity

- Arranging of inlet and outlet of refrigerant on opposing sides of manifolds is preferable, as it makes a significant impact on uniform refrigerant distribution, as a result – on smooth evaporator surface temperature gradient and overall performance.

- Microchannel evaporator is a preferred choice when compared to finned-tube coil: in the present study, it delivers 9.0% more capacity (measured with an optimum charge of refrigerant), positively affects system efficiency (up to 7.5%), and ensures smooth air outlet temperature.