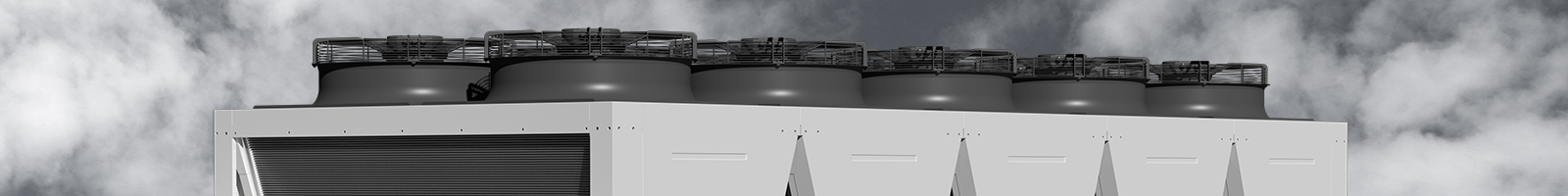

INNOVATIVE FREE COOLING CHILLERS

Air-based free cooling uses low-temperature ambient air as a cooling medium for chilled water systems, thus providing significant opportunities to generate energy savings. The more time the chilled water system can operate in the free cooling mode, the greater savings it can deliver.

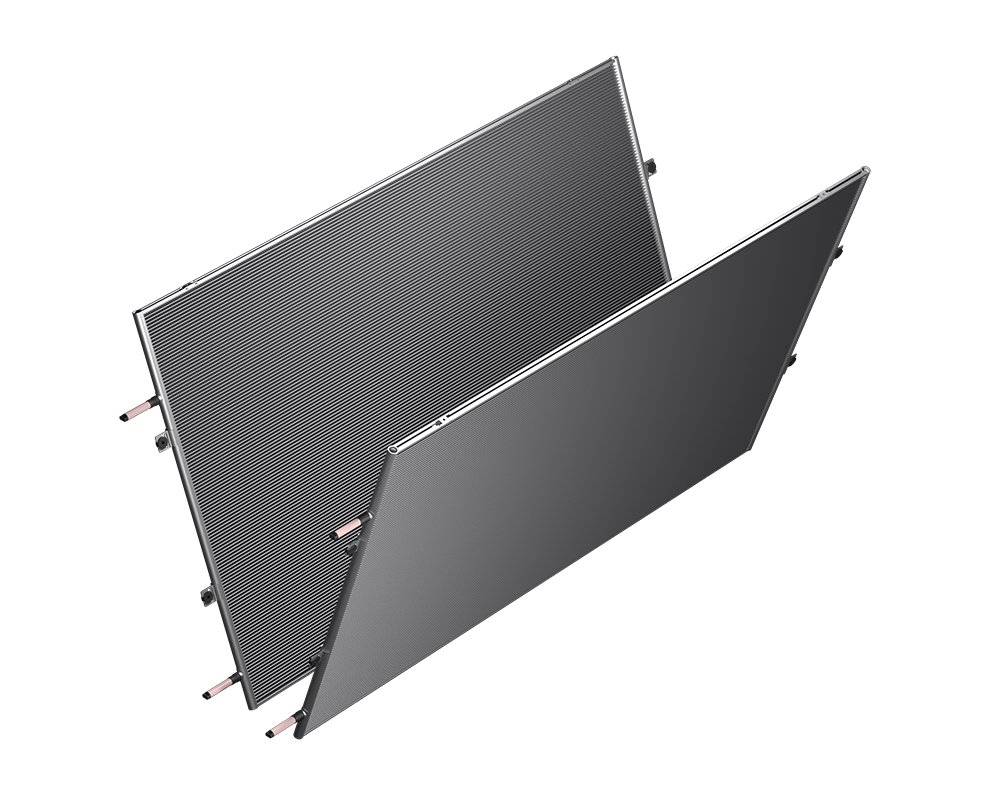

Although free cooling technology is not new and widely used in many installations, there are a variety of ways to raise its efficiency, including adopting innovative heat exchangers, engaging the partial free cooling operation mode, and the use of advanced control techniques.

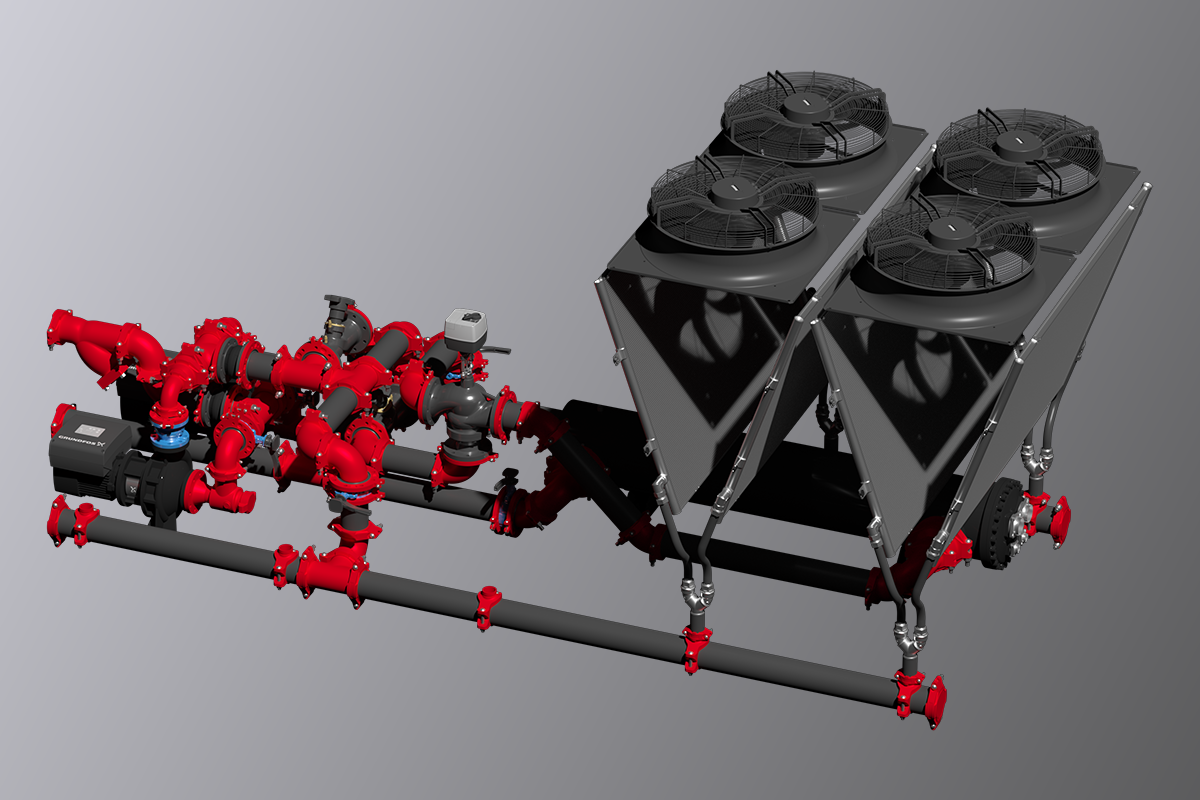

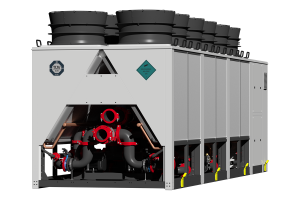

The free cooling system found in Kaltra chillers has been engineered using all of the above technologies and delivers remarkable high energy savings while extending chillers’ operating envelopes.

Kaltra offers a comprehensive range of free cooling chillers with different types of compressors and optimized for various applications, starting from air conditioning solutions to process cooling to data center cooling. The whole portfolio includes highly efficient, feature-rich models to select from.