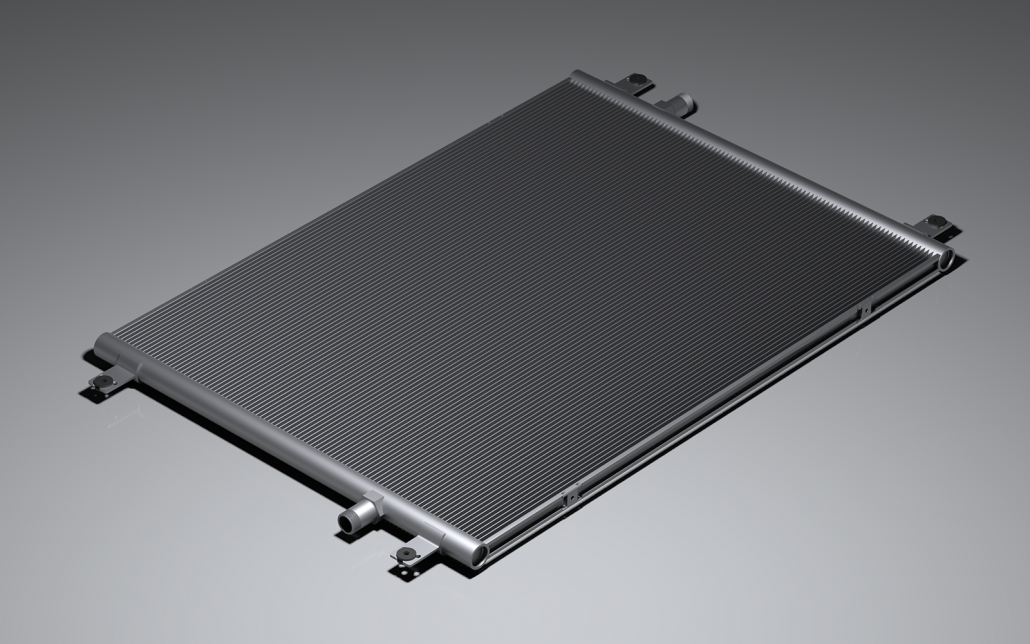

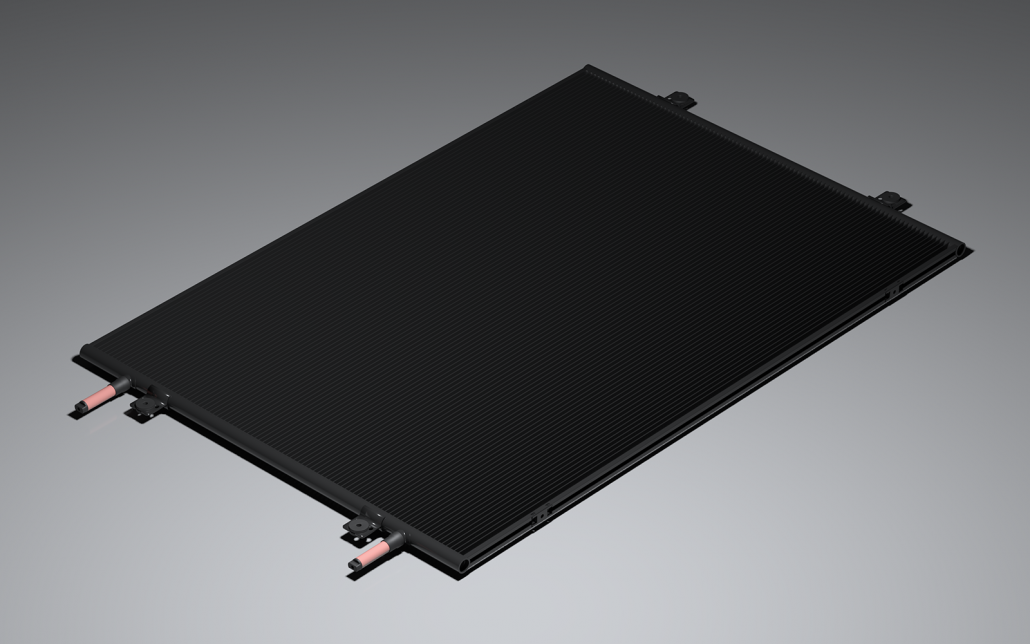

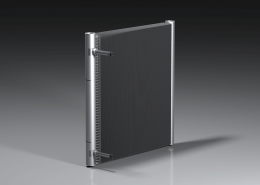

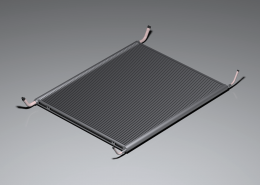

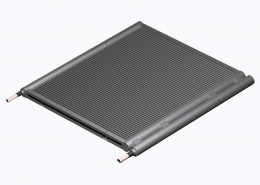

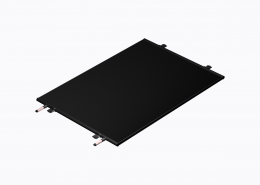

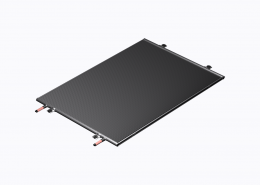

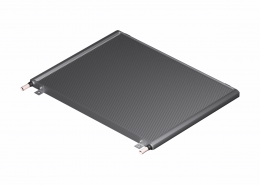

HIGH-PERFORMANCE MICROCHANNEL COILS FOR HVAC AND REFRIGERATION

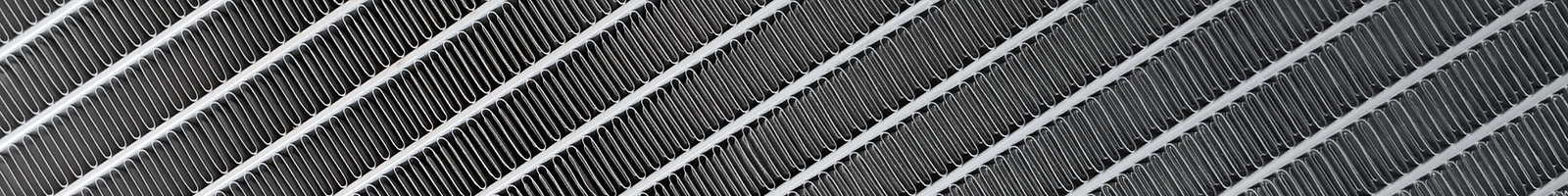

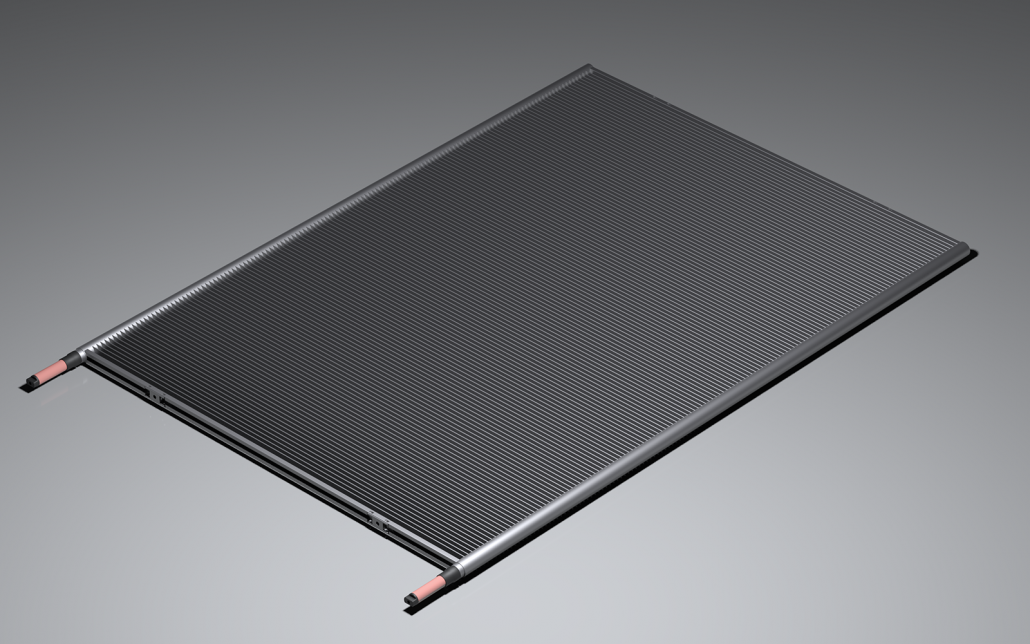

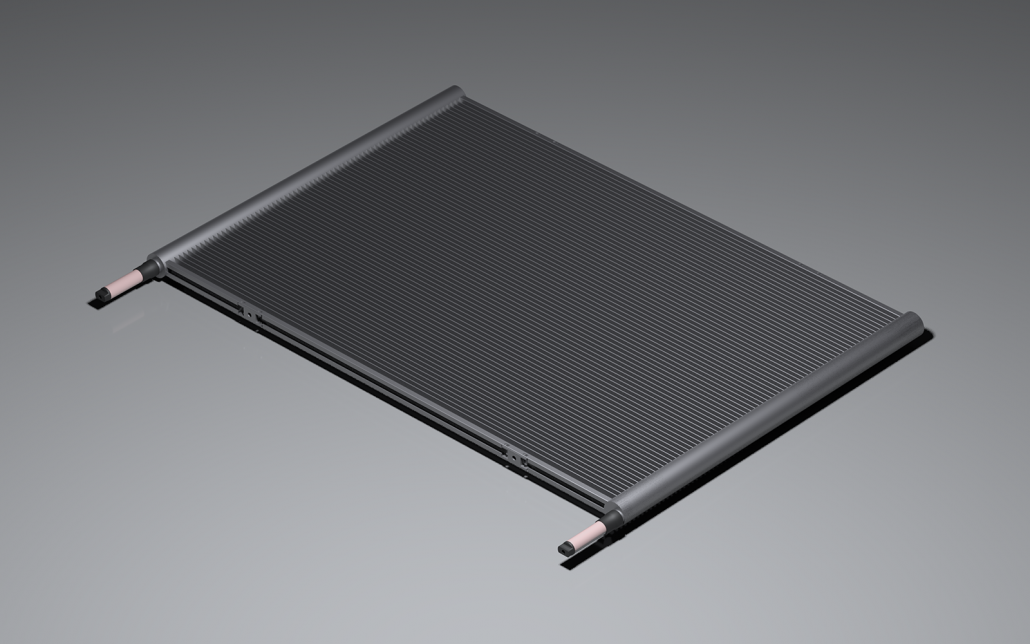

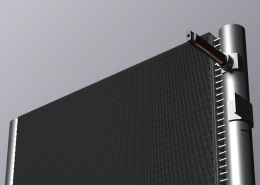

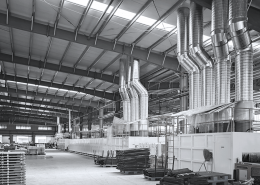

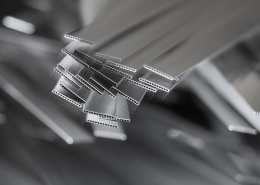

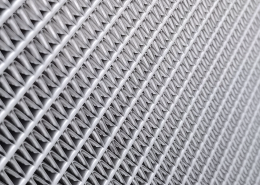

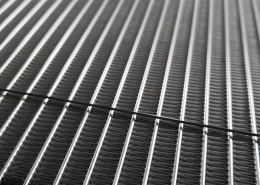

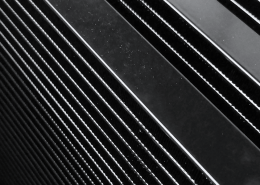

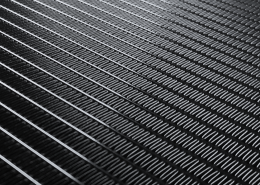

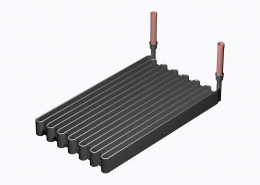

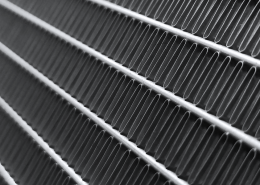

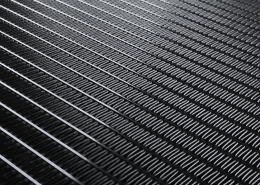

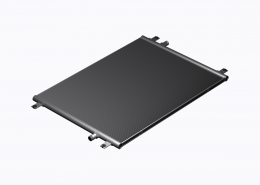

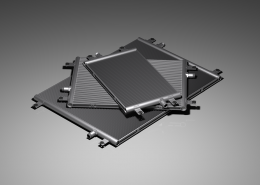

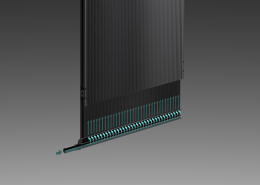

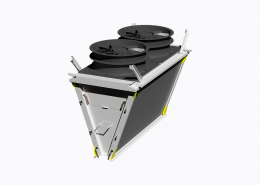

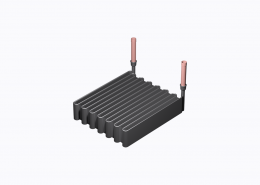

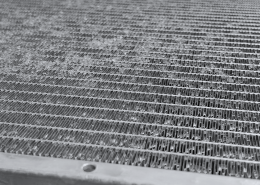

Microchannel coil technology delivers superior HVAC performance through enhanced heat transfer across three critical zones: optimized air-side exchange between aluminum fins and ambient air, maximized thermal conduction between fins and flat tubes, and improved refrigerant-side transfer within multi-port tubes. These engineering advances result in a dramatic 20-40% increase in overall system efficiency compared to traditional finned-tube heat exchangers.

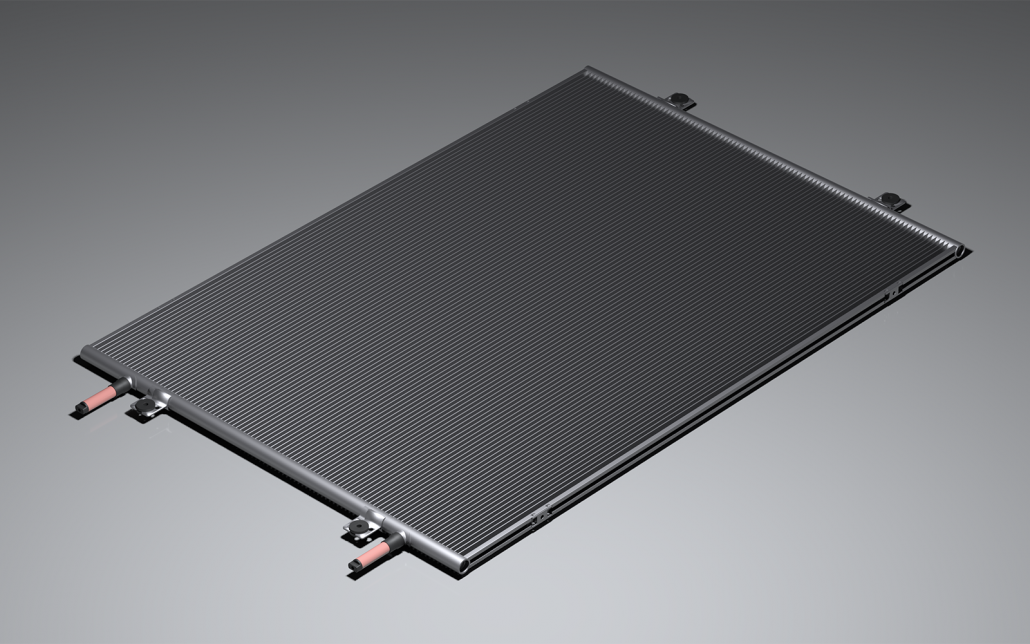

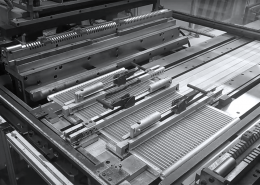

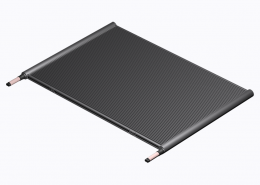

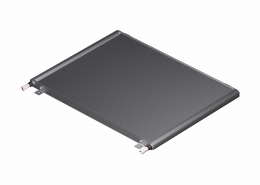

Kaltra’s advanced microchannel coils revolutionize thermal management with industry-leading heat transfer efficiency and corrosion protection. These precision-engineered coils excel in multiple applications, from refrigerant condensers to evaporators and fluid coils. By combining superior thermal performance with compact design and lightweight aluminum construction, Kaltra’s microchannel coil technology consistently outperforms traditional finned-tube heat exchangers in efficiency, longevity, and reliability.