Kaltra puts forward innovative high-tech coating to improve heat exchanger performance

Surface coatings play an important role in increasing the service life of heat exchangers and, consequently, HVAC equipment’s lifespan. Surface coatings may also positively impact heat transfer efficiency – but this potential remained unfulfilled until now.

Kaltra always devoted particular attention to the coating technologies and techniques, offering the highest corrosion protection level for its microchannel coils and further continues activities to improve its products. A significant step in that direction has been made with the development of HiRad™ surface treatment. The advent of this new surface coating technology is owed to continued investments in research and development made by Kaltra in recent times.

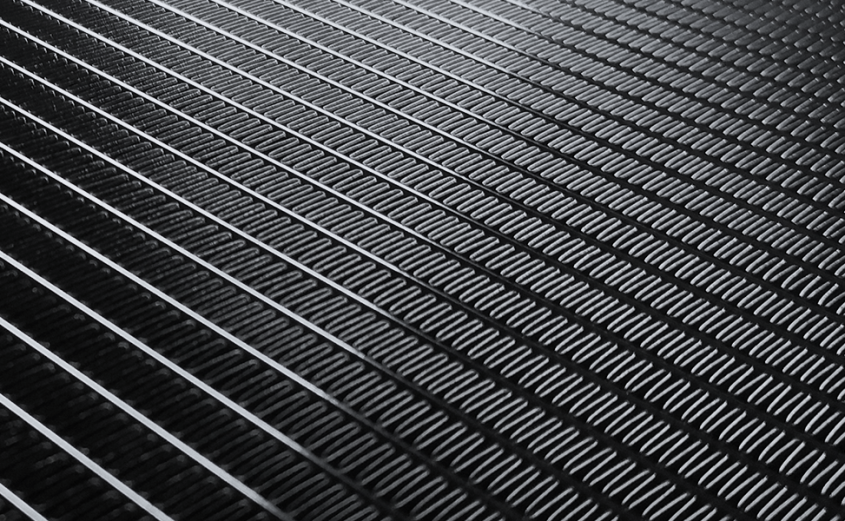

HiRad™, a new coating for aluminum microchannel heat exchangers developed by Kaltra, offers clear benefits for the customers:

- More than 10%-higher capacity, achieved by improved heat conduction and heat dissipation

- Anti-corrosion properties – comparable with those of epoxy coatings

- Remarkably low cost

- Perfect appearance of the heat exchangers

HiRad™ coating creates an extremely low painting layer on the aluminum surface, not affecting the heat exchanger’s airside performance. It is durable, does not require any special servicing, and suitable for the hardest operating conditions. Through these properties, HiRad™ is up to the highest requirements for superior performance and HVAC equipment reliability.

As of now, HiRad™ coating is available for the complete lineup of its microchannel heat exchangers. Along with HiRad™, Kaltra offers other types of protective surface treatments: epoxy electrophoretic coating and trivalent chromate conversion coating.

Along with other innovative HVAC solutions, Kaltra is this week showcasing its HiRad™ coating at Chillventa 2020, the leading HVAC event held in Germany.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 89 943 99-8-66 or visit www.kaltra.com