INNOVATIVE HEAT TRANSFER TECHNOLOGY

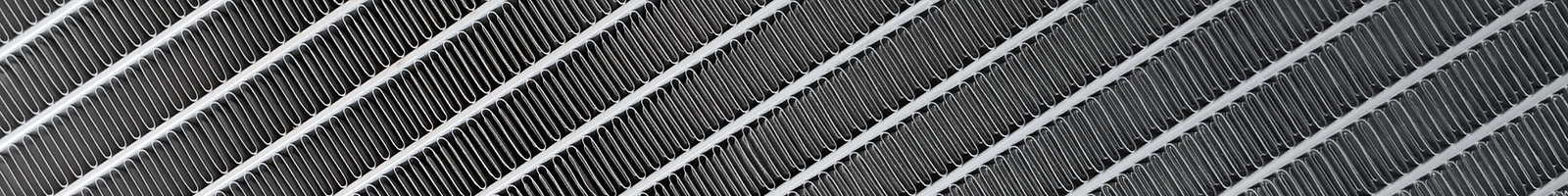

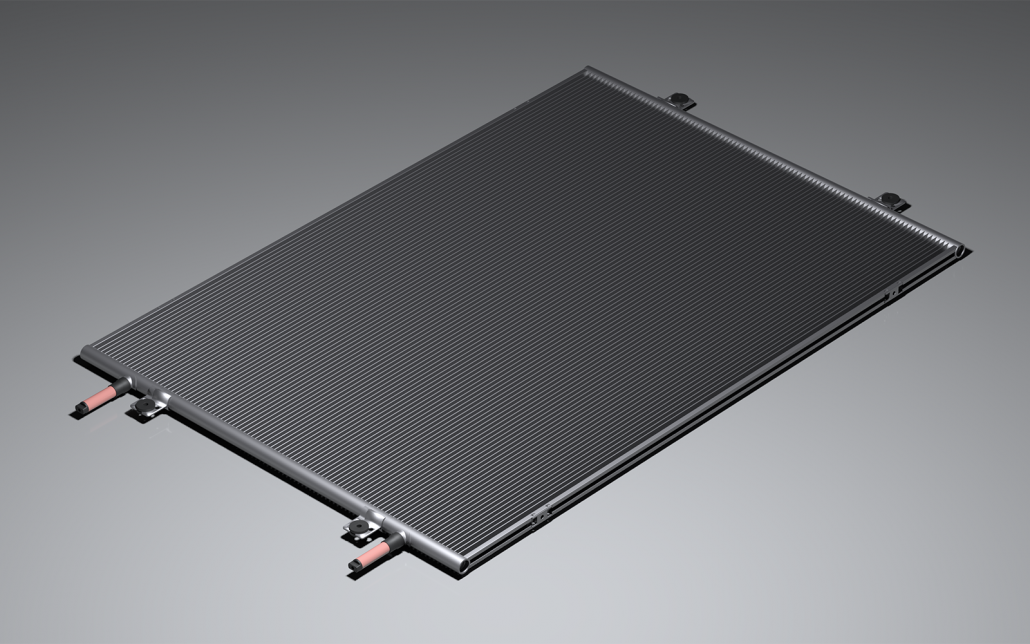

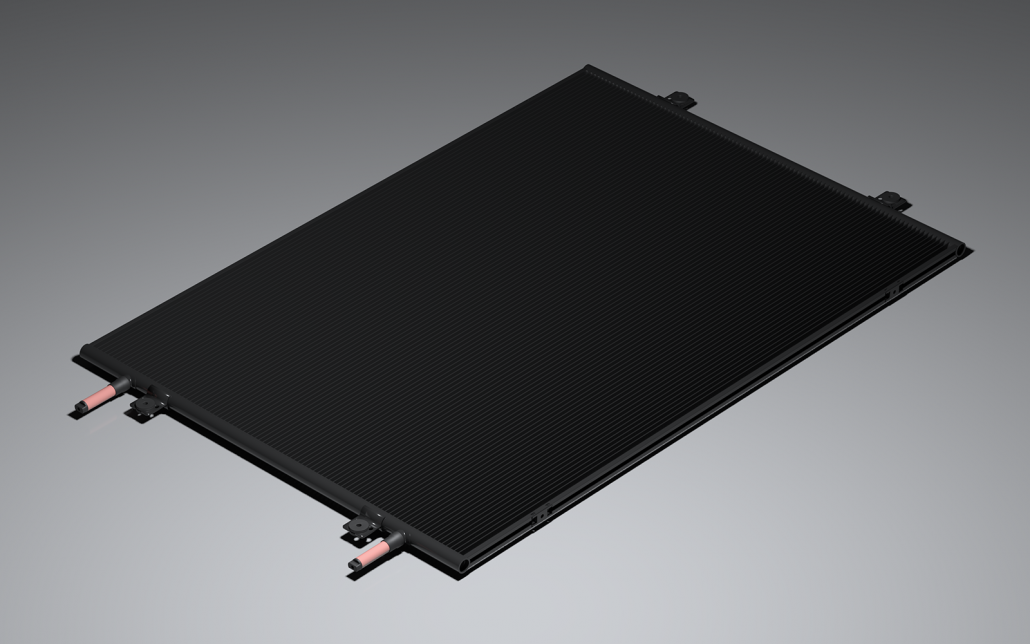

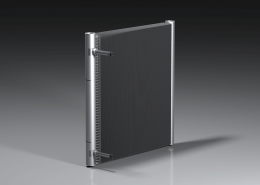

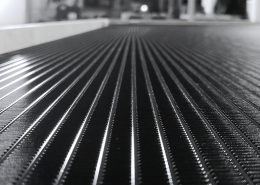

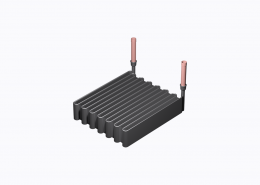

Microchannel condensers are the most efficient air-to-refrigerant heat exchangers, offering heat transfer rates several times higher than those of traditional finned-tube coils. Their high efficiency, combined with other advantages—such as low airside pressure drops, reduced refrigerant charge, lighter weight, and smaller face areas—makes microchannel condensers an indisputable choice for modern HVAC and refrigeration systems.

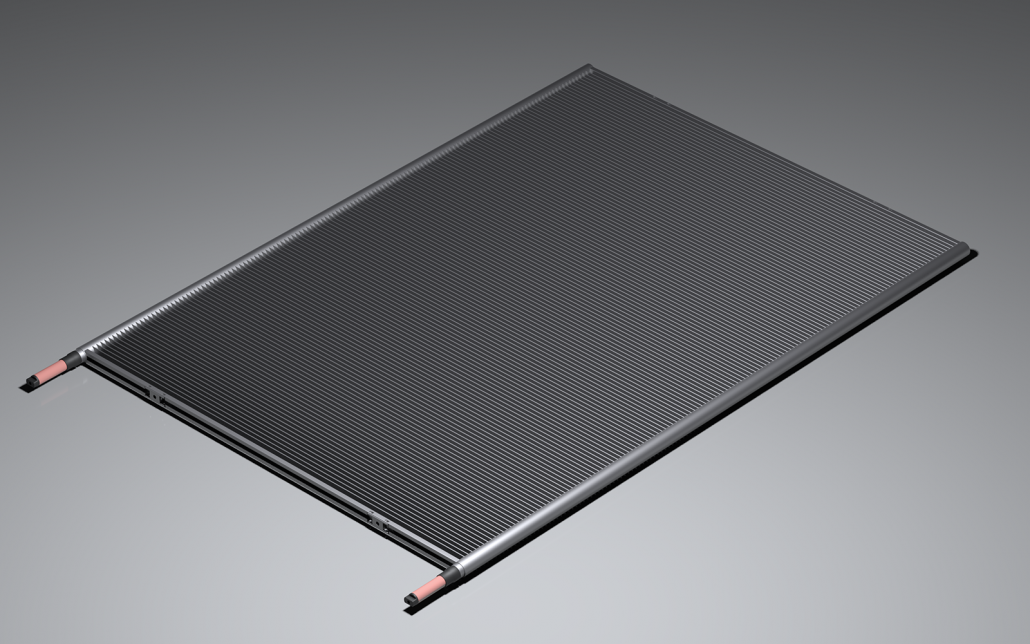

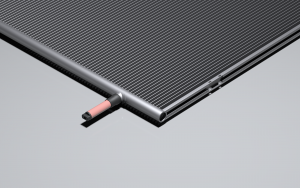

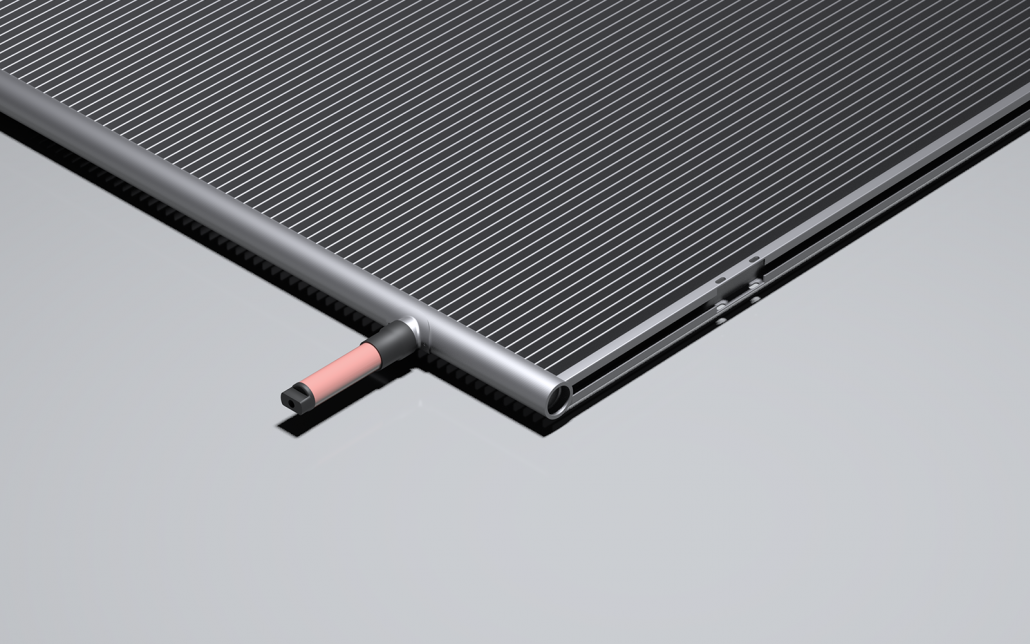

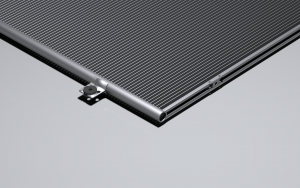

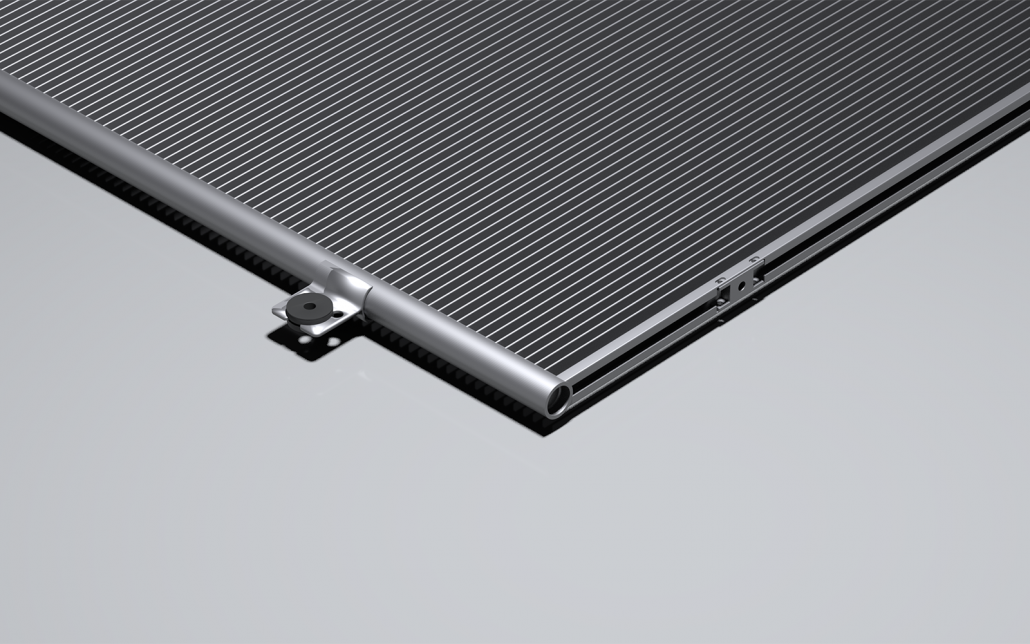

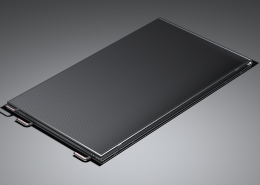

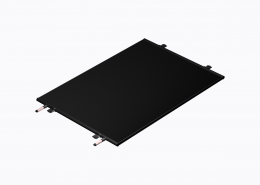

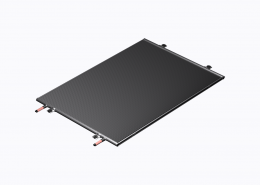

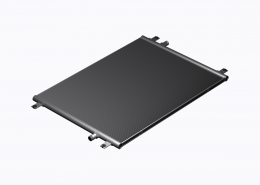

Kaltra’s microchannel condenser range features models with horizontally or vertically oriented multiport tubes in single or multiple pass designs, compatible with various refrigerants. Customers can choose from a diverse range of dimensions and customize condenser coils by combining multiport tube widths with various fin types and pitches, as well as select the appropriate connections, mountings, and protective coatings to meet specific application requirements.

Besides their exceptional thermal efficiency, our microchannel condensers—engineered with advanced aluminum alloys and state-of-the-art protective coatings—offer outstanding corrosion resistance, proven through extensive field experience. We stand by their durability and reliability by providing the best warranty terms available on the market.

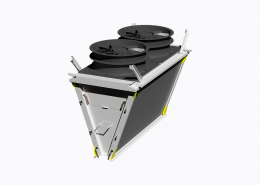

Advanced microchannel condenser technology is ideal for a wide range of HVAC systems, including air-cooled chillers, air-source heat pumps, condensers, and rooftop units, offering unparalleled efficiency and reliability.