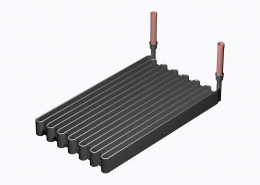

SMALLEST HEAT EXCHANGERS FOR REFRIGERATION AND COOLING

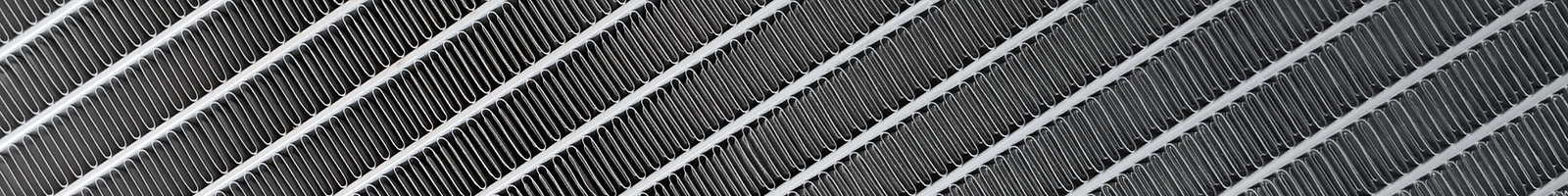

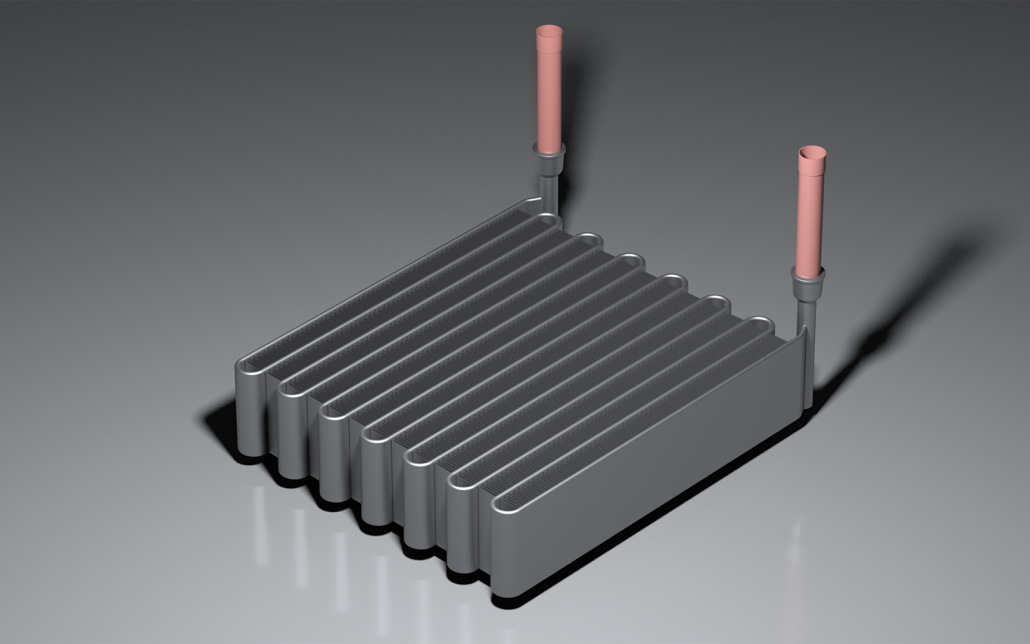

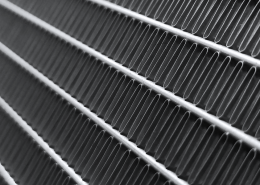

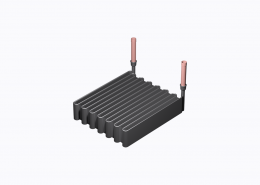

Serpentine heat exchangers are among the smallest—most compact and minimal-volume—microchannel coils available, featuring an innovative design without manifolds. This arrangement makes them ideal for space-saving and lightweight cooling applications where size and efficiency are critical.

The reduced internal volume of these coils is especially advantageous for systems using flammable or toxic refrigerants such as propane, ammonia, and other environmentally friendly alternatives. By minimizing refrigerant charge requirements, these heat exchangers help meet stringent safety and environmental regulations, ensuring compliance with modern standards.