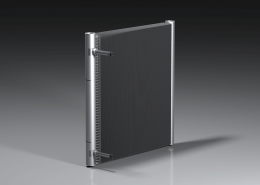

ENERGY EFFICIENCY

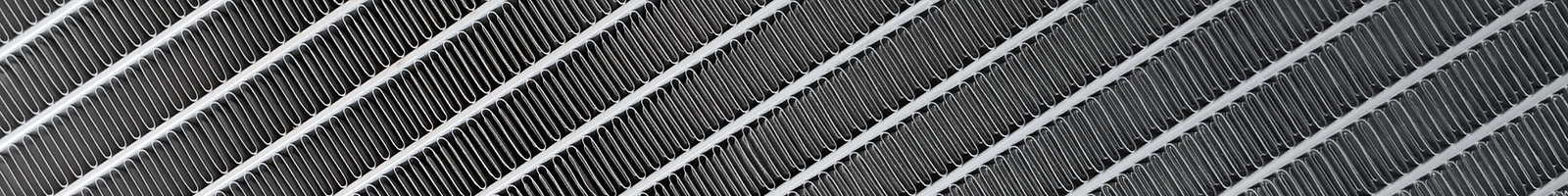

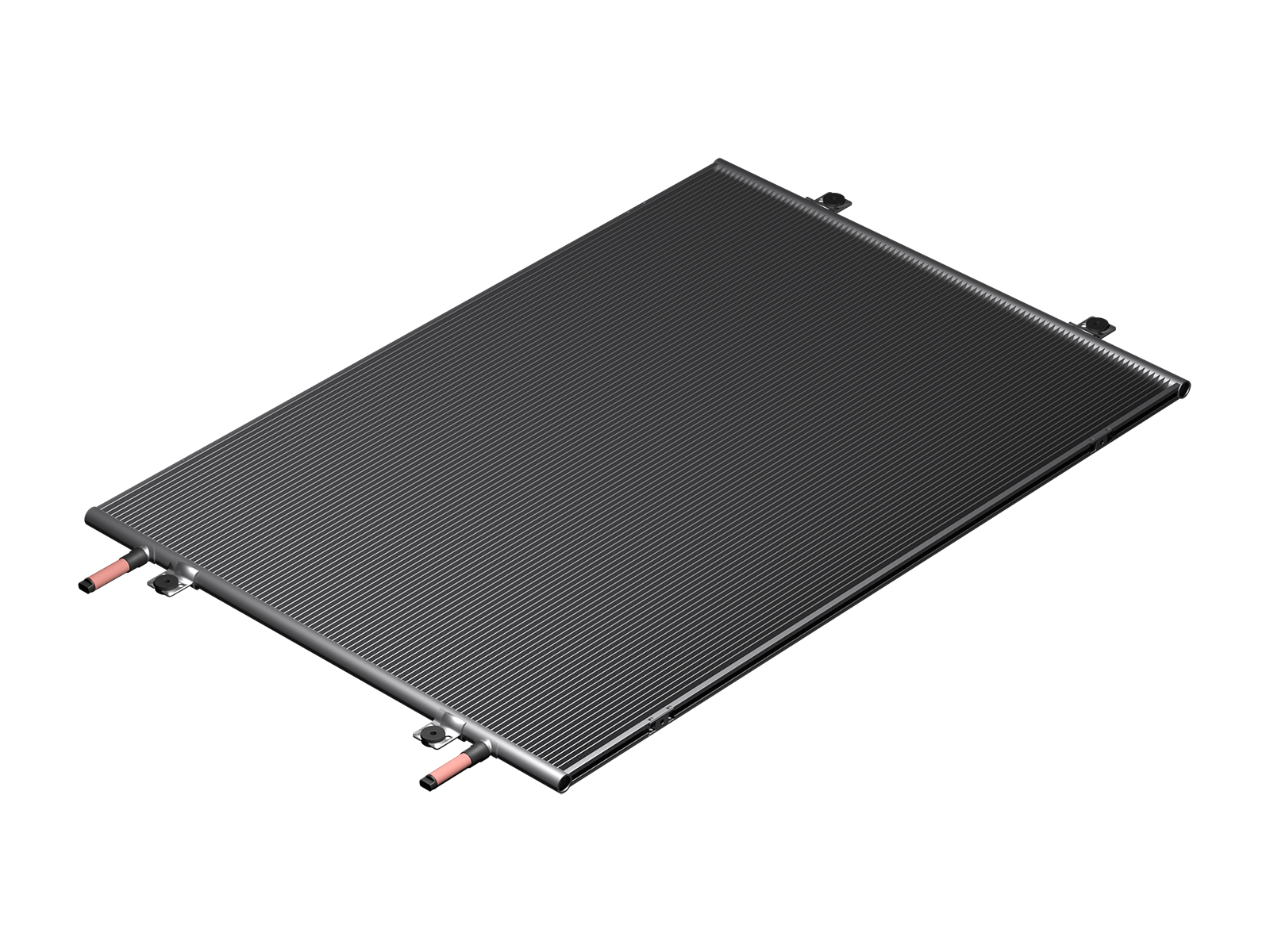

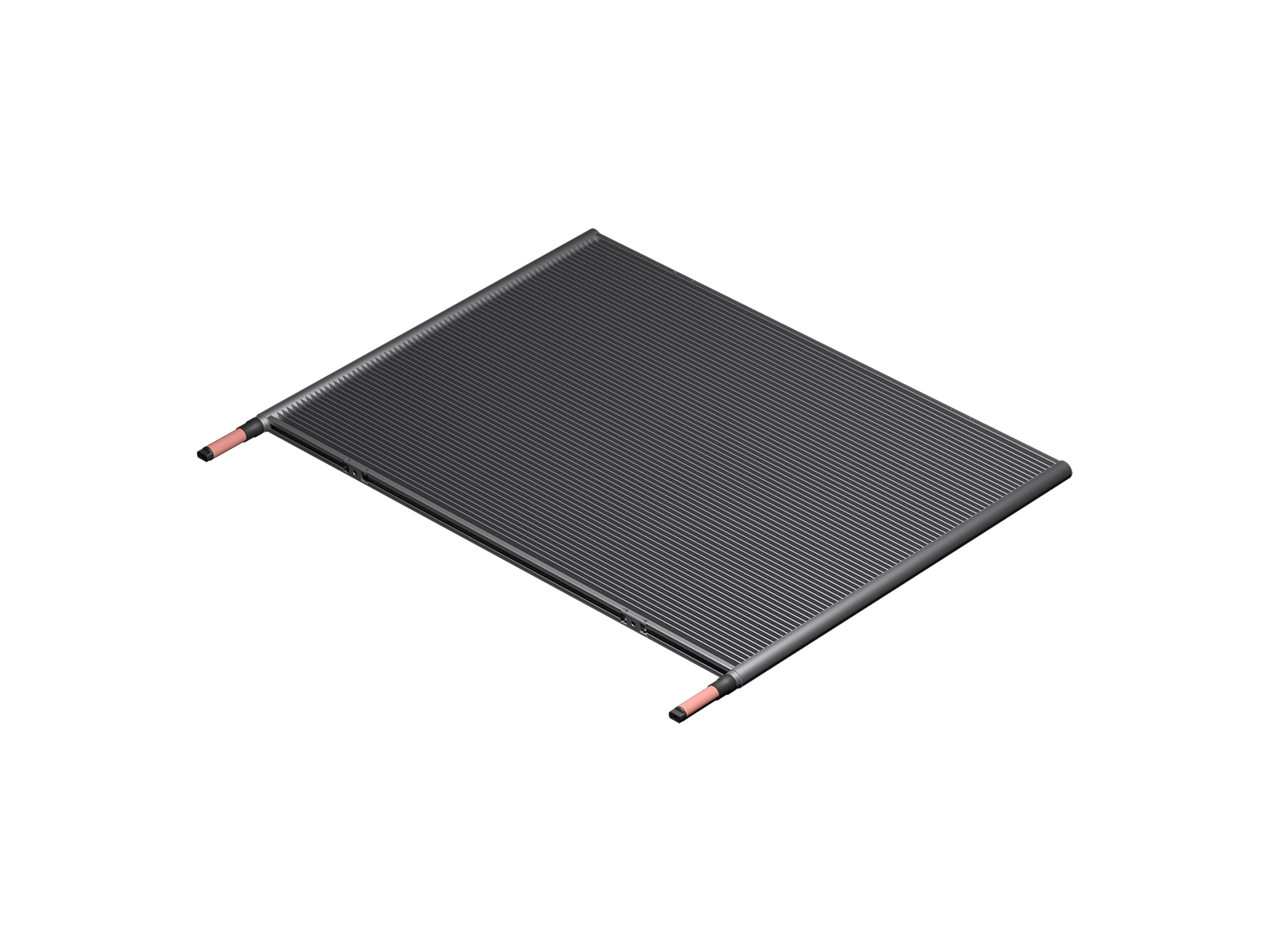

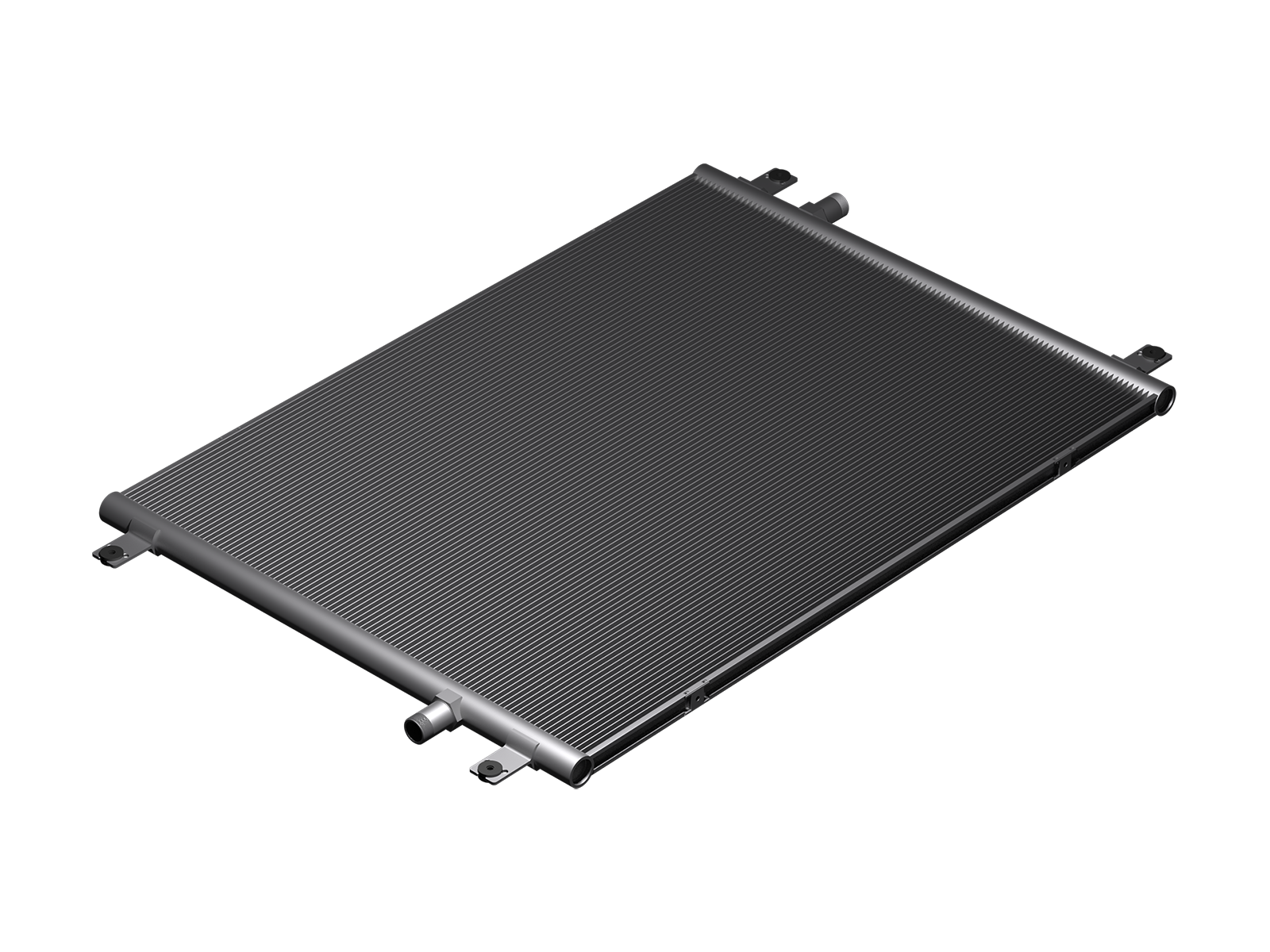

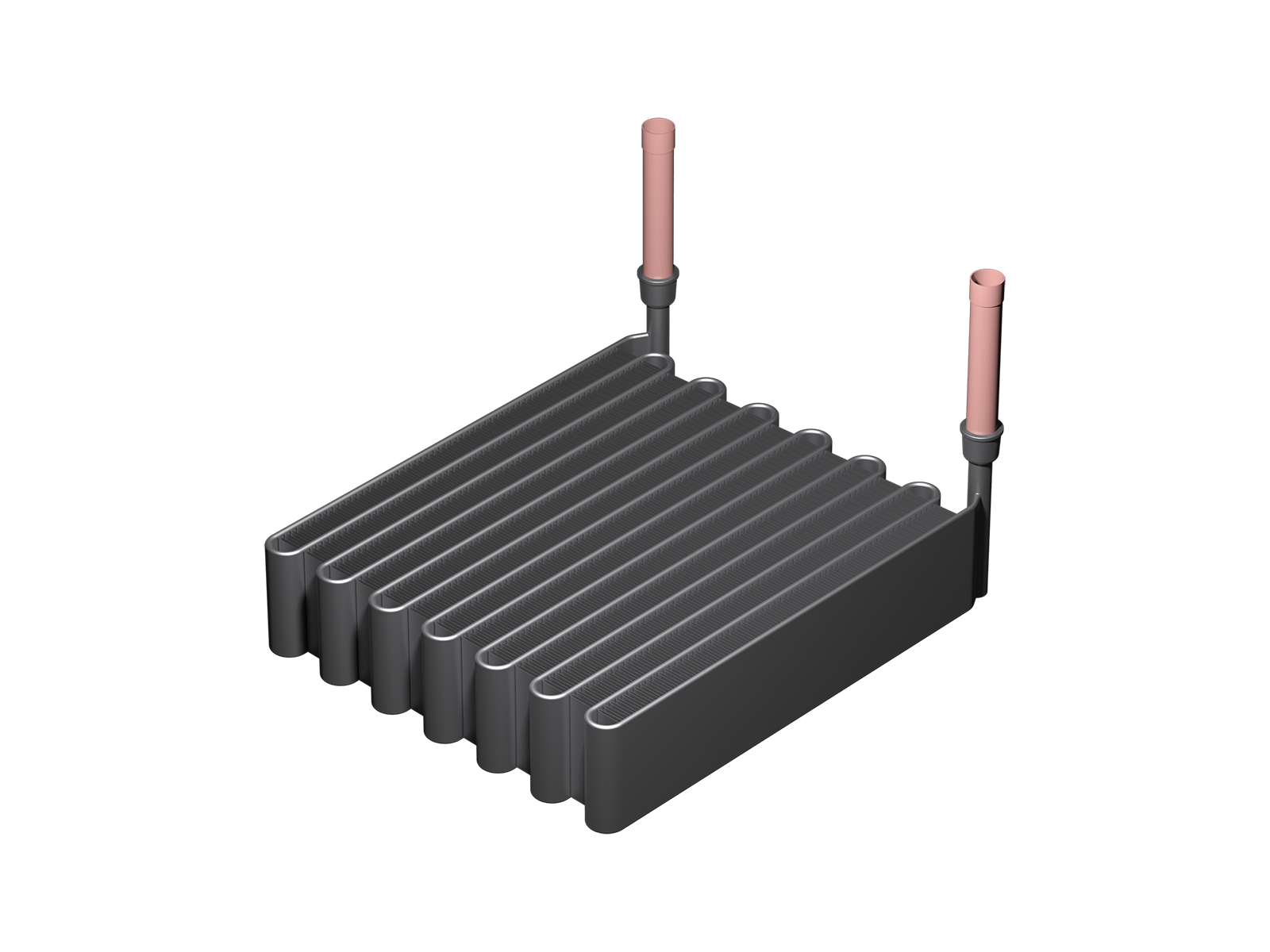

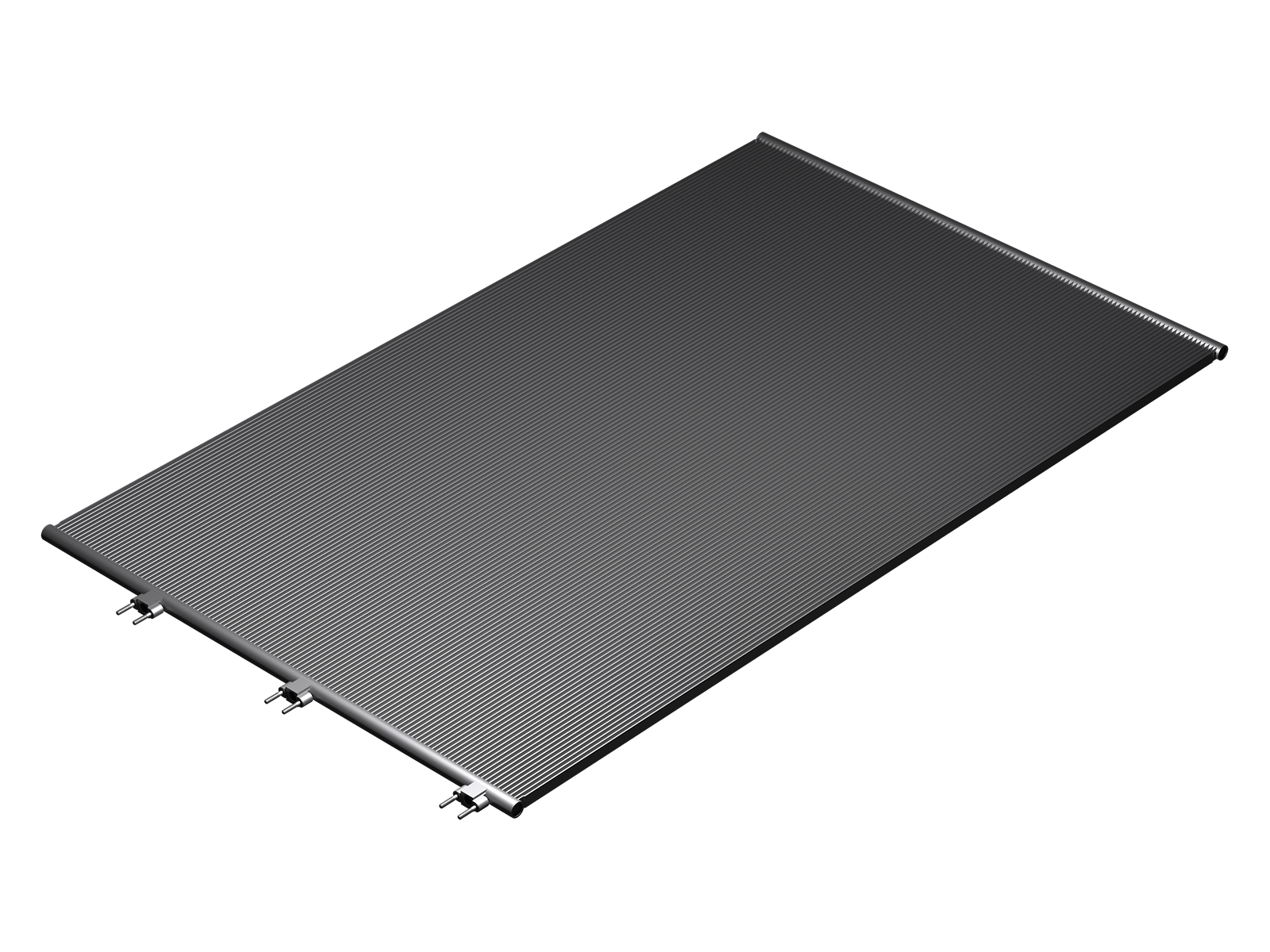

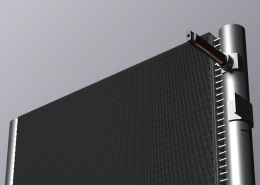

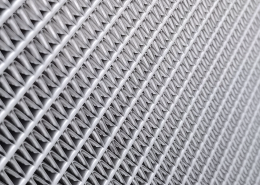

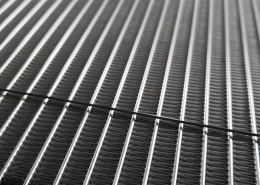

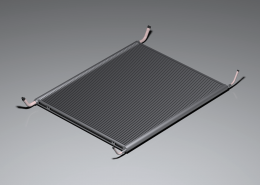

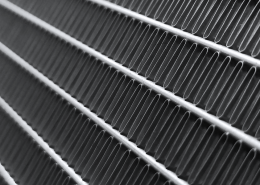

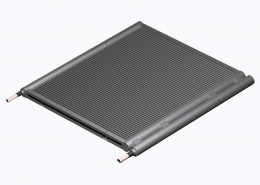

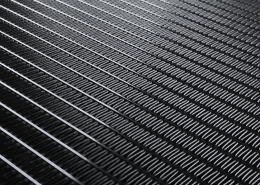

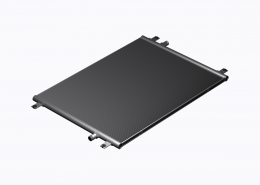

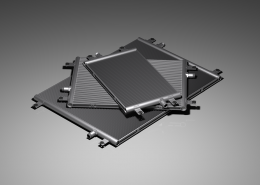

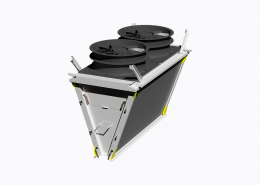

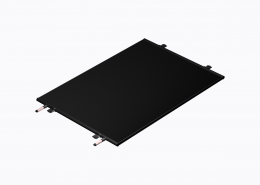

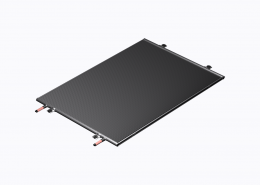

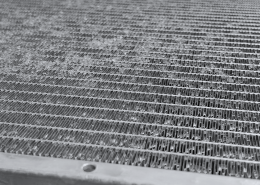

Energy efficiency is a key advantage of microchannel heat exchangers, driven by their high heat transfer rates, low airside resistance, compact size, and lightweight design—all contributing to significant energy savings.

IMPROVED RELIABILITY

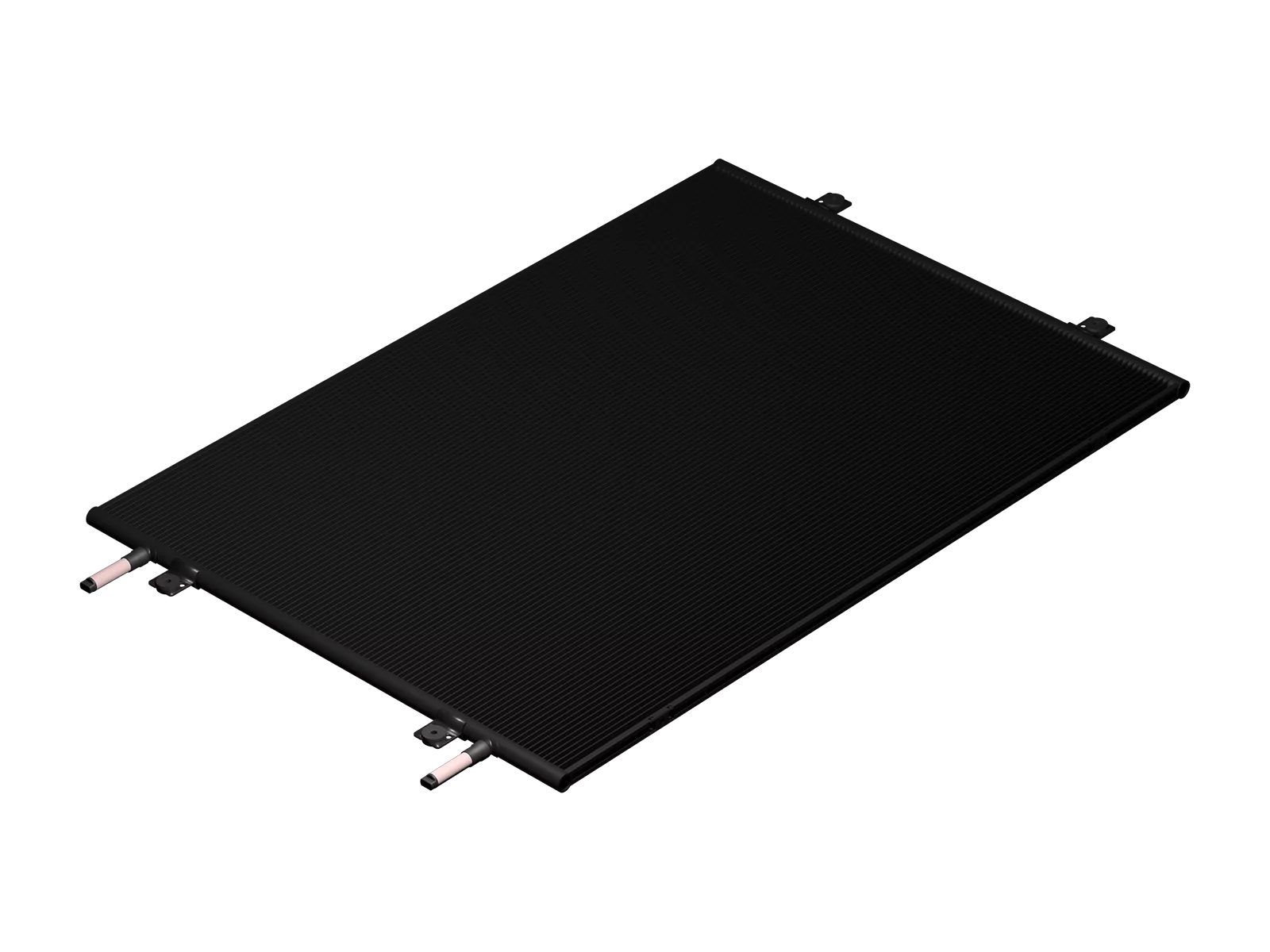

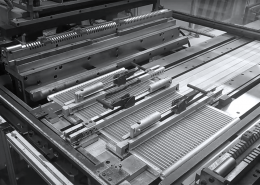

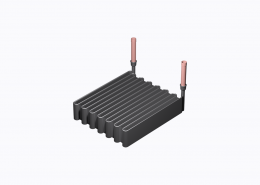

The reliability and lifespan of our heat exchangers are significantly enhanced through the use of state-of-the-art aluminum alloys and an advanced brazing process, with optional e-coating offering further improvements.

ENVIRONMENT PROTECTION

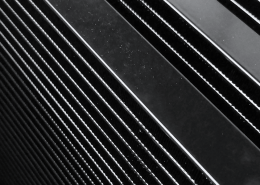

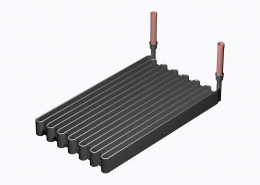

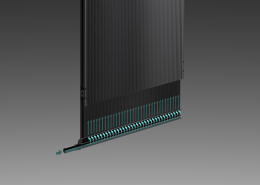

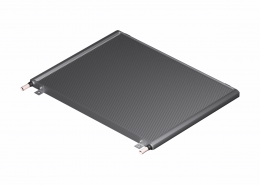

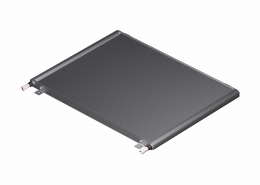

Reduced internal volume and adaptation to low-GWP refrigerants, including natural fluids, make our heat exchangers the most environmentally safe solution available on the market.