Air-cooled condenser assemblies for end-customers and OEMs

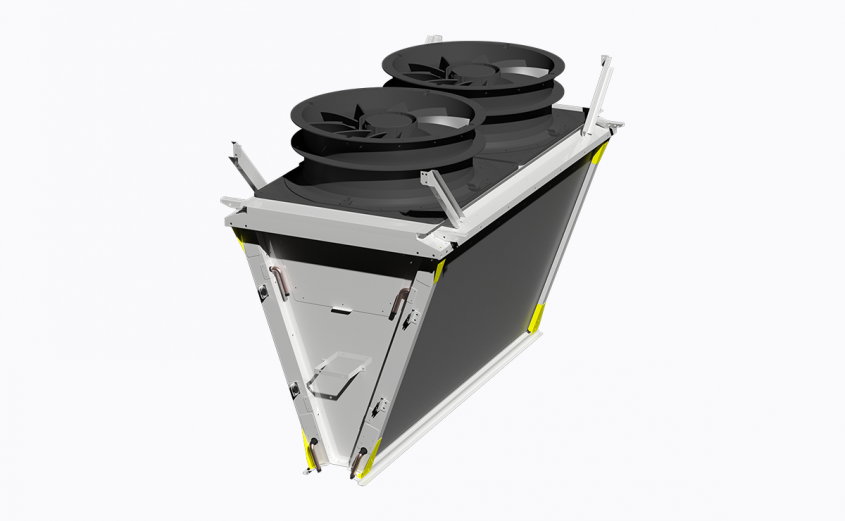

Based on recently introduced low-charge microchannel condensers, Kaltra offers high-performance V-shaped condensing coil assemblies intended for use in air-cooled chillers and stand-alone condensers.

In addition to in-depth optimization for low-GWP refrigerants such as R1234ze, R452b and other, new condenser banks demonstrate improvements in many aspects compared to the previous generation, including:

- 20% increase in heat transfer rates

- Low internal volume and charge reduction up to 70%

- Higher corrosion resistance achieved by the use of 9000 series aluminum alloys

The performance of new condensers has been tested and proven across the full range of operating conditions, including running in extreme ambient conditions and harsh environments. Higher heat rejection enables OEMs either to lower condensing temperature and lift the system efficiency or to reduce condenser size and lower the system cost. Of particular interest is high resistance to any type of corrosion: even uncoated, microchannel condenser coils showed no traces of corrosion or chemical attack after 36 months operation in salted seashore atmosphere under high humidity.

New condenser banks are fully customizable to OEMs requirements. Physical structure, dimensions, connections, and mountings – all can be engineered and manufactured to specification. Depending on performance requirements, microchannel condensers can be configured for desired capacity by varying tube profiles, fin pitches, number of passes, etc. Protective treatments include e-coating and TCP (trivalent chromium process) coating, making new condensers the most reliable solution on the market. Increased time of post-treatment bathing for deposited TCP coating ensures its homogeneity and sealing properties, thus further improving the corrosion behavior of the heat exchangers.

Reduced use of raw materials has also significantly contributed to reducing product costs.

Headquartered in Germany, Kaltra Innovativtechnik GmbH designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 911 715-32021 or visit www.kaltra.com