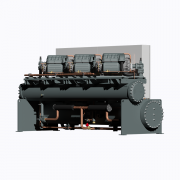

New chillers for Arla dairy processing plant

Processing of milk products requires the correctly designed process in order to attain end products of the highest quality. Processing of milk involves pasteurization, a technique that destroys pathogens in milk and makes it safe to drink. Pasteurization necessitates the use of chilled water to cool down the milk after the heating-up process to prevent the deterioration. During the cooling process, the pasteurized milk has to be cooled to 0°C. Thus, the production of chilled water for dairy processing operations is a vital part of producing safe and high-quality consumer products. Tight thermal control is also a crucial requirement for dairy processing facilities.