Hydrophilic topcoat for microchannel heat exchangers

Condensation management is essential for ensuring the efficient function of heat exchangers and is critical for the correct operation of evaporators.

Hydrophilic topcoats, or water-resistant surfaces, are effective in environments with excessive condensation, as they enable water to flow easily off the heat exchanger surface based on the lowered surface tension, thereby enhancing heat transfer performance in wet and frost conditions. At the same time, hydrophilic coatings protect heat exchangers from the corrosive effect of water and provide excellent protection in salty environments.

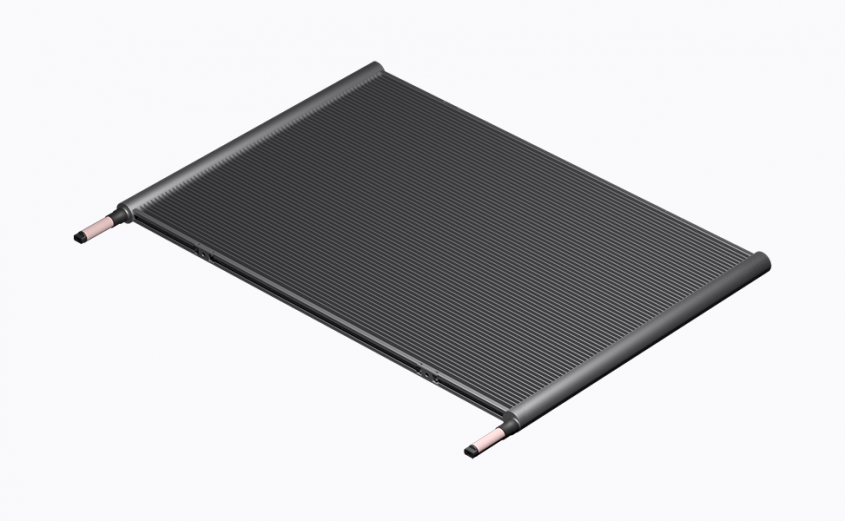

Up to now, hydrophilic topcoats were primarily available for traditional finned-pack coils. Based on an increased interest in heat pumps based on microchannel heat exchangers, in particular, in reversible models where MCHE coils are also used as evaporators, Kaltra has developed a new coating chemistry and method of applying hydrophilic topcoats suitable for this type of coil.

A coating is considered hydrophilic if the contact angle of a water droplet’s edge with a surface is less than 90 degrees. This refers to the angle that a droplet of water makes at the point of contact with the surface – a lower angle means better coating performance. Field tests conducted on Kaltra’s microchannel heat exchangers treated with a hydrophilic agent have shown that a contact angle is less than 30 degrees with high critical surface tension.

Based on laboratory tests and validation exercises, we recommend hydrophilic treatment for coils exposed to wet and/or frost conditions, particularly evaporators, including those used in air-source heat pump applications and for dehumidifying coils.

Laboratory experiments have also shown increased evaporation heat transfer rates of hydrophilic-treated coils, specifically at high Reynolds numbers, in the range of 25-55%.

In summary, the use of a hydrophilic polymer:

- Improves condensate drainage

- Increases performance in wet conditions

- Provides antimicrobial protection

- Enhances corrosion resistance of the heat exchanger, contributing to its extended service life

The chemical agent used for Kaltra’s hydrophilic coating was designed by Nihon Parkerizing, a Japanese-based industry leader in surface treatments.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 253 421 07 or visit www.kaltra.com