Strong demand for compact microchannel coils triggered production capacity expansion at Kaltra

Due to the high and constantly growing market demand for compact microchannel coils, Kaltra expands its manufacturing capabilities of serpentine heat exchangers by installing new tube bending machines and assembly lines equipped with semi-automatic core builders, fin mills and fin inserting machines.

The rapid growth in the popularity of compact, low-volume heat exchangers, especially ones of serpentine type, is caused by heightened interest in deploying HVAC and refrigeration solutions based on low-GWP – but flammable and/or toxic – gases, including natural refrigerants such as propane and ammonia.

Compact heat exchangers require high accuracy in assembling, and precise assembling machinery is crucial to ensure low tolerances for all coil components. Besides this, new manufacturing equipment provides increased throughput, almost doubling heat exchanger production per shift.

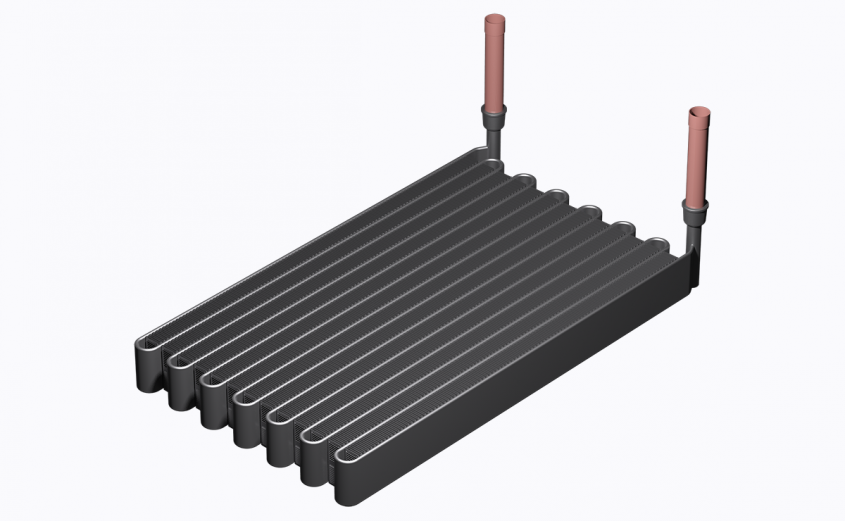

Serpentine microchannel coils excel through small internal volume thanks to their manifold-less design: compared to traditional microchannel coil design, the volume is about 2 times smaller, while their heat transfer area is greater for the same overall size. Being also flexible in geometry and circuit arrangement, serpentine coils are ideal for compact applications – as condensers, evaporators, and fluid coils.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 253 421 07 or visit www.kaltra.com