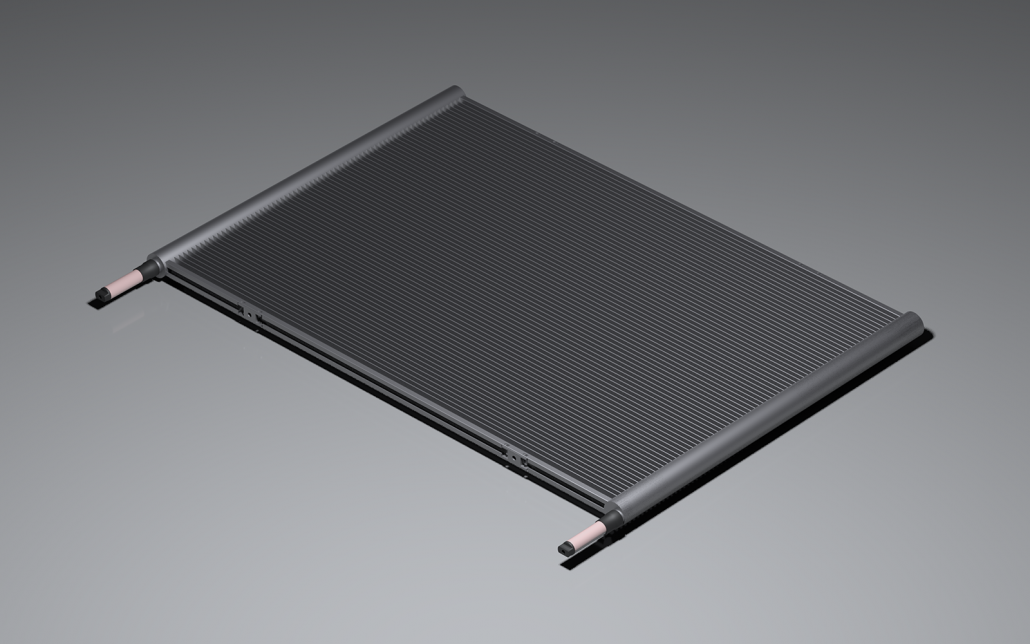

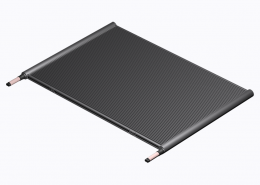

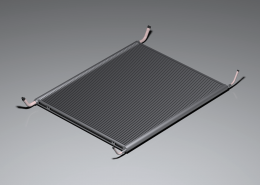

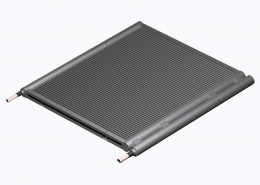

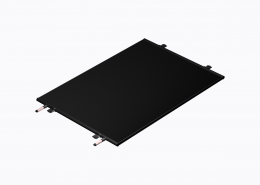

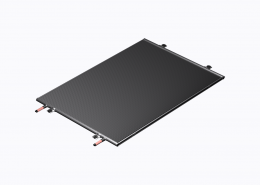

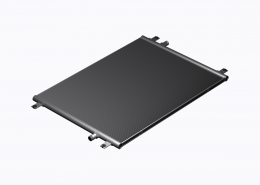

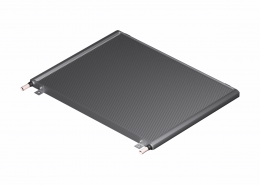

MICROCHANNEL HEAT EXCHANGERS ADOPTED FOR EVAPORATOR AND HEAT PUMP APPLICATIONS

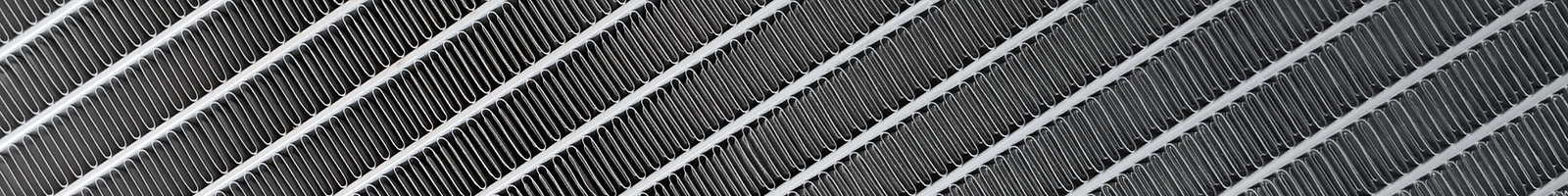

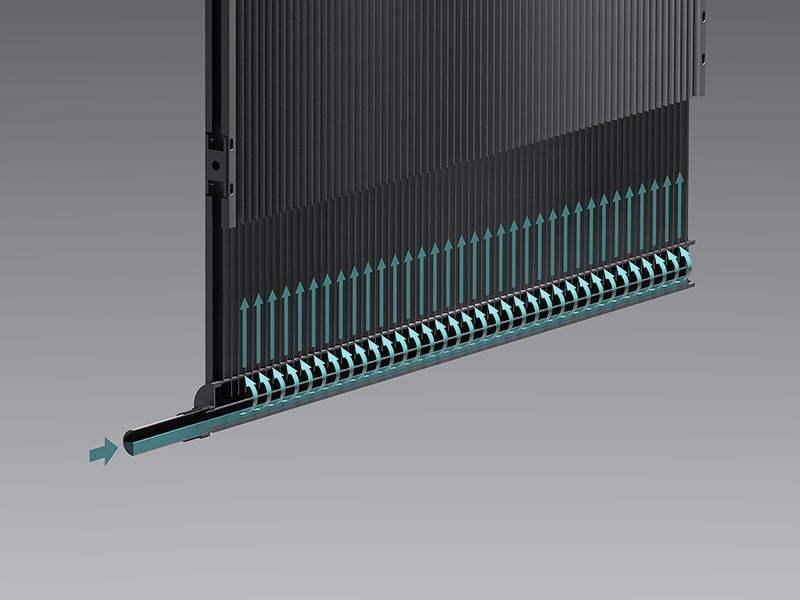

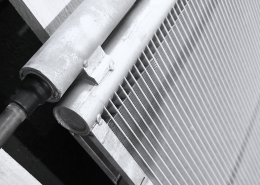

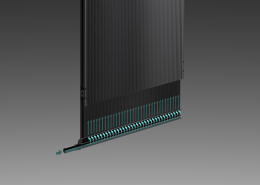

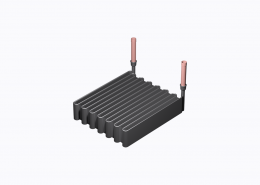

In our microchannel evaporators, an internal refrigerant distributor is used in combination with vertical microchannel tube orientation and oversized manifolds. This provides optimum thermal performance over a wide range of operating conditions and design issues, ensures uniform refrigerant distribution in the inlet manifold and equal refrigerant injection across all the multiport microchannel tubes, and counteracts the effects of outlet manifold pressure drop. Additionally, vertical tube orientation ensures free condensate runoff.

Refrigerant distributor of the evaporator can be operated in reverse refrigerant flow for heating duty in the heat pumps and by using switching valves that allow the same microchannel evaporator to then be used as a condenser for heating operation.