Dual-circuit microchannel evaporators to revamp performance of air-source heat pumps

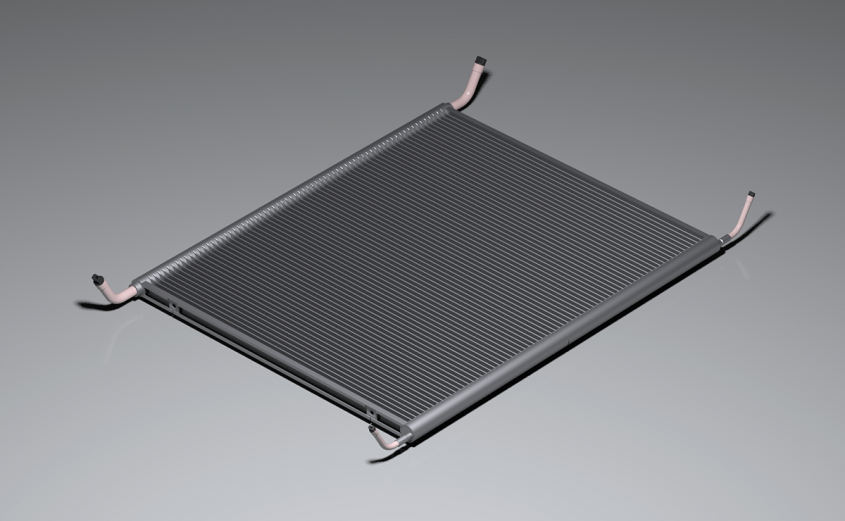

In carrying forward work on microchannel evaporator designs, Kaltra presented its successive generation of coils intended for both indoor and outdoor use in air conditioners and air-source heat pumps. Thanks to the ingenuity of its dual-circuit arrangement, new evaporators offer maximum efficiency while at the same time dealing with challenges of operation in frosting conditions.

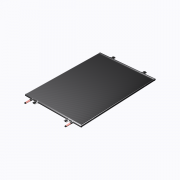

In air-source heat pump systems, louvered-fin microchannel heat exchangers are subjected to frequent frost and defrost cycles when used as outdoor evaporators, markedly reducing heating service time of the system. The low conductive thermal resistance of microchannel tubes leads to the temperature of the fins being close to the refrigerant saturation temperature and to the higher temperature difference between air and fin surface, augmenting heat transfer rate and capacity of the coil during the heating period. However, low fin temperature (and characteristics of fin surface) cause the early formation and rapid growth of frost that blocks airflow and results in significant performance degradation of the coil. Frost accumulation increases with the increase of air velocity and relative humidity of the inlet air.

Creating a heat pump design that effectively copes with the frosting phenomenon without compromising performance was a primary goal of the challenging research process that successfully developed a 2-circuit, single-pass louvered-fin evaporator with vertical tubes and assisting (optional) dehumidification coil.

While retaining all benefits of microchannel coils, new evaporators offer vital characteristics which are essential for efficient operation of air-source heat pump systems:

- Efficient, even refrigerant distribution for coils of any size, including those with long inlet manifolds.

- Maximized heating service time in heat pump systems.

- Heat pump system may continue operation in parallel with coil drying or defrosting, which can be initiated at any time, thus forbidding evaporator frost and eliminating damages caused by cyclic coil icing.

- Problem-free condensate removal based on the vertical arrangement of microchannel tubes.

- Reverse operation in condenser mode.

- Possibility of bent coil designs.

We recommend installing a dehumidifying coil in front of the unit’s evaporator for extreme environmental conditions with high rates of ice buildup. Dehumidifier assists in collecting most of the moisture from the airstream before it enters the evaporator, while it itself is highly resistant to frosting due to low fin pitch and thin coil core.

Dual-circuit evaporators are available in width ranging from 400 to 1200mm and up to 2000mm in height.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 253 421 07 or visit www.kaltra.com