Biomass power plant cooling with dry coolers

In power plants, the largest water consumers are cooling systems, as a large amount of heat must be removed to condense the steam used to drive turbine generators. Historically, cooling was provided by water sources – rivers and lakes, but nowadays, more and more power plants use dry cooling systems that use little to no water. These systems have higher capital costs but use more than 95% less water than wet cooling systems.

Power plants that burn coal, biomass, natural gas plants, and some other plant types generate electricity by boiling water to produce steam, which is then passed through a turbine. Steam must be condensed back to a liquid and returned back to the steam generator.

Water conservation is the best practice for modern power generation companies. Eni, a multinational oil & gas company headquartered in Roma that operates in many fields, including biomass power plants, is among them. A feasibility study and analyses that were carried out for a horizon of 25 years demonstrated that the use of dry steam condensers also in terms of ROI with a pay-off period of 6.5 years for 10MW installation and 8.0 years for a 50MW system.

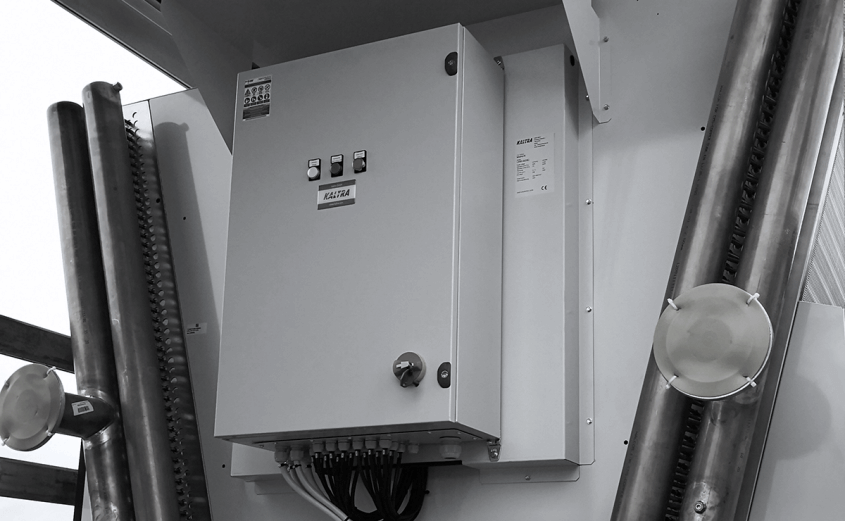

The customer selected Kaltra’s industrial Mistral dry coolers for its biomass power plant cooling, relying on proven quality, long warranty period, and wide range of available options. Cooling units have been configured with low-energy, large-diameter electronically-commutated (EC) fans, feature low sound output thank fan diffusers, and are equipped with dual fan speed controllers. Epoxy-coated heat exchangers ensure long operating life, offering a high level of corrosion protection for Mistral coolers.

As an alternative to wet cooling that requires about 3 cubic meters of water for 1MW generated power, dry cooling by air is increasingly used for new-build power plants with a steam cycle. At Kaltra, we develop cooling solutions, including dry cooling and hybrid systems with evaporative pre-cooling, for power plants. We pay special attention to systems’ lifespan, energy efficiency, and reliability. In summary, our solutions reduce power plant vulnerability to water scarcity and ensure increased generation revenue, providing sustainability to water stress problems in thermal power plants that utilize wet cooling systems.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 253 421 07 or visit www.kaltra.com