Evaporative cooling helps to boost cooling equipment efficiency

Adiabatic cooling was first used in the Roman Empire. For 2000 years, people have been using water evaporation to cool down the surrounding air in all types of climate systems, including modern, highly advanced cooling systems, where engineers combine this ancient principle with modern technologies.

Adiabatic cooling technology is already used in many solutions and has even more exciting opportunities, e.g., in traditional heat rejection units such as air-cooled condensers and fluid coolers that use ambient air to cool process fluids or gases. Lowering inlet air temperature closer to wet-bulb temperature enables improvements in cooling capacity and efficiency.

Wetted Pad Cooling vs. Water Spray Systems

Discussions have recently centered around two different solutions – wetted pad cooling and water spray systems. The significant advantage of evaporative pads over the water spray system lies in the possibility of water reuse, and it’s saving. Taking into account that newly designed all-aluminum evaporative pads are corrosion-resistant, self-cleaning, can be used with untreated water and able to withstand bacterial growth, we chose this solution for our evaporatively-cooled systems. The pros and cons of each solution are summarized in the below table:

|

EVAPORATIVE PADS |

WATER SPRAY SYSTEM | |

|

Water treatment |

NOT REQUIRED |

REQUIRED |

|

Water reuse |

YES |

NO |

|

Bacterial protection |

YES |

NO |

|

Corrosion resistance |

YES |

NOT APPLICABLE |

|

Additional air resistance |

YES |

NO |

All-aluminum evaporative pads are made from the water-retaining, coated finned structure, which prevents the buildup of mold and dirt. Water is distributed over the length of evaporative pads by spraying through orifices located on the header pipe and collected into a drip tray for further reuse. At air velocities of up to 3m/s, there’s no need in droplet eliminators thank labyrinth-type structure of the pads. For air velocities of up to 2m/s, saturation efficiency reaches as high as 90%.

The water supply module consists of an immersed-type circulation pump, water tank, water quality monitor, and controls – all housed in a weatherproof enclosure and connected to potable water supply for topping up when necessary.

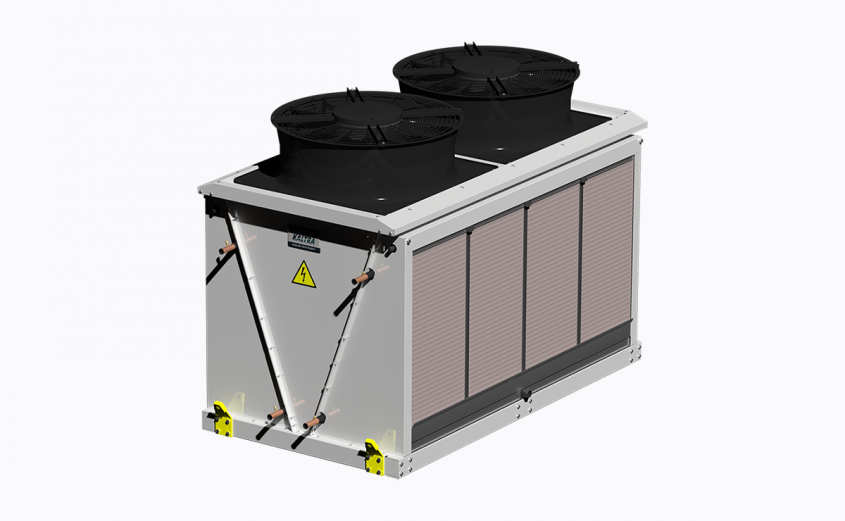

In addition to recently introduced condensers and dry coolers, Kaltra continues the development of evaporatively-cooled equipment, expanding it with evaporatively-cooled chillers.

As of December 2019, Kaltra’s evaporatively-cooled condensers successfully operate for three years under harsh environmental conditions with ambients up to 50°C and relative humidity of up to 80%, in salted seashore atmosphere and under sandstorms.