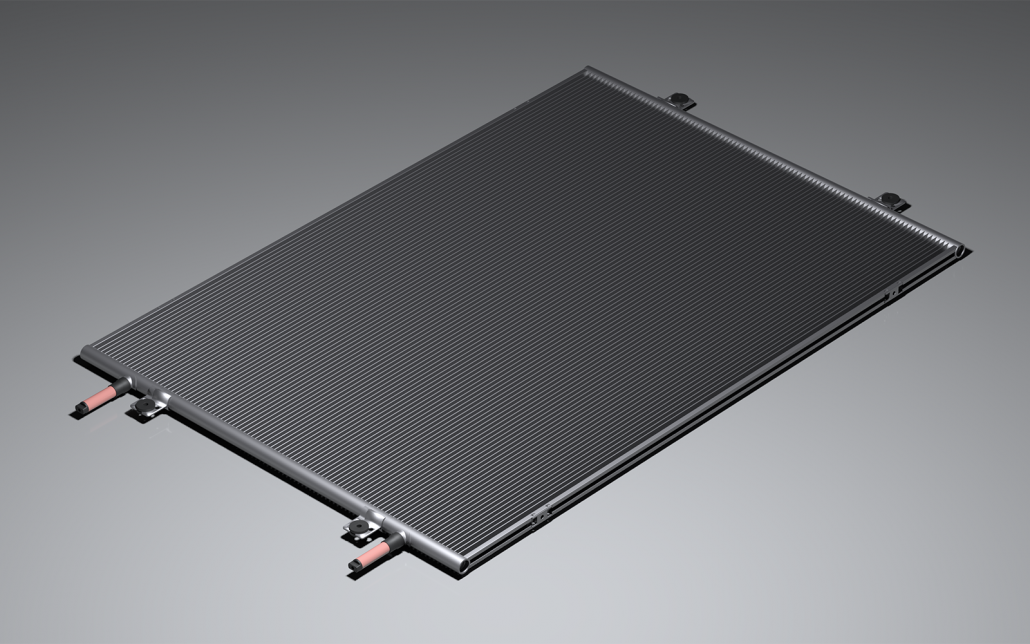

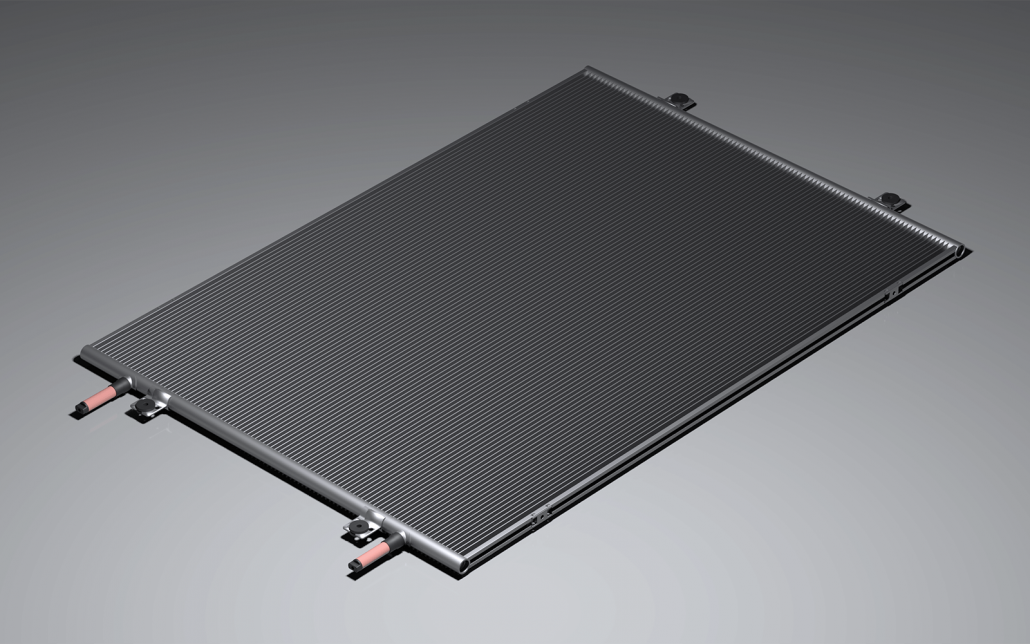

NANO-SCALE Cr(III)/Ce(III) COATING FOR MICROCHANNEL HEAT EXCHANGERS

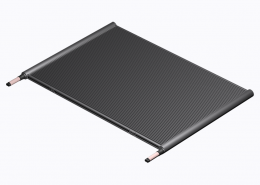

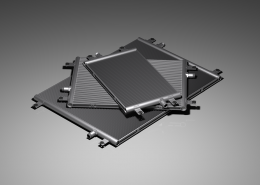

Developed by Kaltra in collaboration with leading experts in modern chemistry, the Nano-scale Cr(III)/Ce(III) Coating is an advanced protective solution tailored for aluminum heat exchangers. After five years of focused research and innovation, this next-generation coating delivers outstanding corrosion resistance while preserving 100% of the coil’s thermal performance.

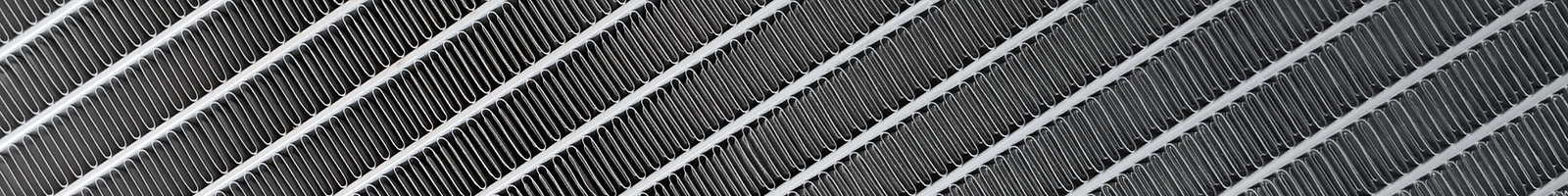

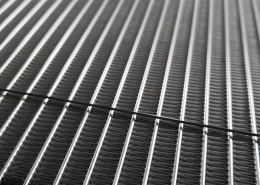

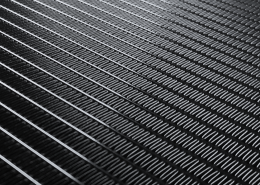

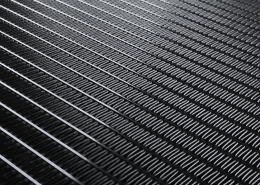

This ultra-thin, uniform nano-level film can be applied to both internal and external surfaces of the coil, providing comprehensive protection. It features hydrophobic properties, extended chemical compatibility—including a broad pH range for heat transfer fluids—and a smooth surface finish with a roughness of just 0.1 µm. In addition to superior functional performance, the coating offers a clean, refined appearance.