Kaltra releases MCHEselect: online selection software for microchannel heat exchangers

With the introduction of its online selection software, MCHEselect, Kaltra enhances customer support by offering comprehensive solutions for microchannel heat exchangers – from performance simulations and product selection to manufacturing and deployment.

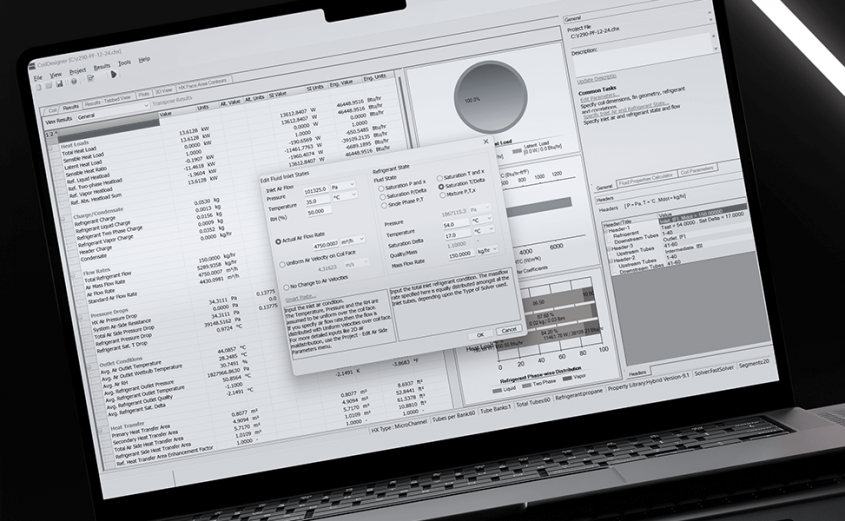

MCHEselect is a versatile coil simulation platform designed to accelerate product development timelines while minimizing both development and production costs. This all-in-one tool empowers users to design heat exchanger coils, simulate their performance, and optimize them for a range of objectives, streamlining the entire process.

MCHEselect supports the creation, validation, performance rating, and simulation of microchannel heat exchangers for a wide range of applications:

- Condenser coils: Tailored solutions for condensing a wide range of HFC, HFO, and natural refrigerants.

- Evaporator coils: Different coil arrangements designed for refrigerant evaporation.

- Fluid coils: Single-phase heat transfer for water, glycols, oils, and specialized fluids.

- Special applications: Reversible coils for heat pump applications, dehumidifying coils, etc.

MCHEselect includes over 180 built-in correlations to accurately solve for key parameters such as heat transfer, pressure drop, and void fraction. The software provides multiple options to balance accuracy and computation time, allowing users to tailor simulations to their specific needs. Utilizing a segment-by-segment modeling approach, MCHEselect ensures detailed and precise performance analysis. The tool has been extensively validated against experimental data, guaranteeing reliable performance and robust results.

The selection process begins by defining the heat exchanger’s purpose, its physical parameters, and operating conditions (working point, including specified air and refrigerant properties). Based on this input, Kaltra specialists design and supply a computational model of the coil, enabling software users to simulate performance across various conditions and with different refrigerants – pure fluids and pre-defined mixtures.

With over 30 multiport tube options, a wide range of fin types and pitches, and various manifold configurations, customers can design hundreds of tailored heat exchanger solutions in both parallel-flow and serpentine arrangements, perfectly suited for specific applications and the most stringent requirements.

The software outputs – encompassing project data, heat exchanger specifications, operating conditions, and performance simulation results – can be saved and downloaded for archiving and further analysis.

Customers are invited to register for software access by completing the inquiry form available on the Kaltra website.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 384 333 48 or visit www.kaltra.com