Kaltra unveils next-generation microchannel evaporator coils – engineered for reversible operation and peak efficiency

Uniform refrigerant distribution and effective condensate drainage have long been among the main engineering challenges in microchannel evaporator design. While Kaltra’s previous coil generations successfully solved these aspects individually, certain demanding conditions — such as low-load operation, frosting, or use in reversible heat-pump systems — continued to push design limits.

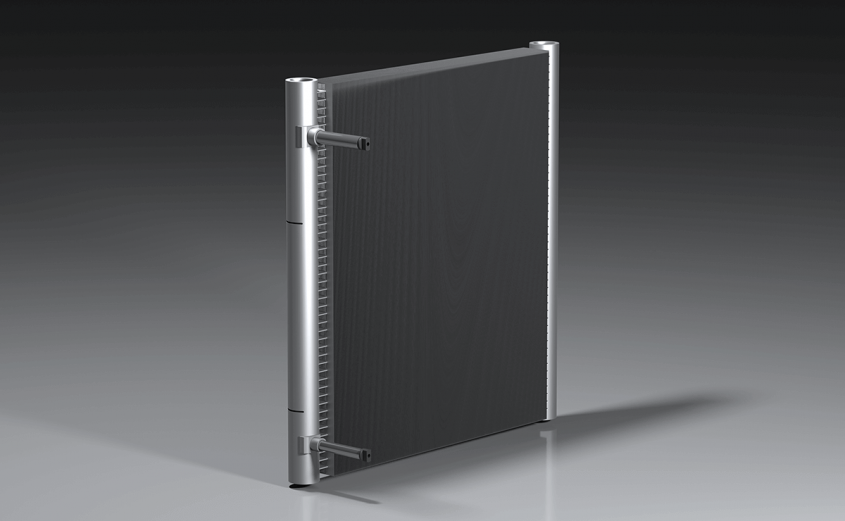

Driven by the goal of achieving flawless performance under all operating scenarios, Kaltra’s R&D team has taken the technology a step further. The result is a new, revolutionary generation of microchannel evaporator coils that ensure stable operation under the most challenging thermal conditions and enable full reversibility as condenser coils in heat-pump applications.

The breakthrough comes with a configuration that places the microchannel tubes horizontally — a layout traditionally avoided in evaporator designs due to poor condensate drainage. Kaltra’s engineers overcame this limitation by replacing individual folded fin stripes with vertical louver-fin plates with leading edges. These edges, which maintain a higher surface temperature than the flat tube, slow the cooling process and direct the formed condensate efficiently downward, ensuring complete drainage and improving frost management and de-icing performance.

Figure 1: Louver-fin plates

With the new vertical louvered-fin plates, condensate drainage and coil behavior under frosting conditions closely match that of conventional finned-tube coils, as the fin geometry of Kaltra’s new evaporator coils closely resembles that of traditional designs — while retaining all the advantages of microchannel technology.

The new horizontal-tube arrangement additionally allows for multi-pass refrigerant circuitry, delivering higher overall heat-transfer performance and superior efficiency in reversible (condenser) operation.

Another key innovation lies in the manifold design. The manifolds feature a special internal geometry with intermediate orifice plates, which promote turbulent mixing of the refrigerant’s gas and liquid fractions. This improves uniformity of refrigerant across all microchannel tubes, ensuring consistent thermal performance and preventing the formation of superheated regions.

The circuit geometry has also been optimized by adjusting the number of tubes in each refrigerant pass, improving overall coil performance for both evaporator and condenser modes. With this design, Kaltra achieves an optimal balance between evaporator and condenser performance, ensuring high efficiency and stable operation in reversible systems.

This latest coil generation was developed with a clear focus on heat pump applications, one of the fastest-growing segments in HVAC technology. Reliable reversibility, consistent drainage under frosting conditions, and minimized pressure drop make these coils an ideal choice for modern heat pump systems that must maintain performance across a wide range of ambient conditions. Extensive laboratory and field testing have confirmed the coils’ outstanding performance under repeated frosting and defrosting cycles.

Several innovative heat pump manufacturers have already integrated the new Kaltra coils into their systems, reporting measurable improvements in energy efficiency and stability across heating and cooling modes.

“The challenge was not only to achieve reversible operation but to make it fully reliable in all real-world conditions — including low-load and frosting scenarios,” said L. Engelhardt, Kaltra’s Business Development Officer. “Our engineering team succeeded in creating a coil architecture that combines performance, manufacturability, and long-term stability. This opens the door to a new generation of compact, high-efficiency heat pumps.”

According to Dr. Fei Yin Liang, Senior Research Engineer at DTS R&D Center, who participated in joint validation tests, “Kaltra’s new evaporator coils demonstrated excellent heat transfer characteristics and stable refrigerant distribution across a wide operating range. The improved condensate management proved especially effective under frosting conditions, which is crucial for reliable year-round heat pump operation.”

With this development, Kaltra further strengthens its position as a technology leader in advanced microchannel heat exchangers. The new evaporator coil generation sets a new benchmark for reversible-system performance, addressing the most critical operational issues of previous designs and unlocking new possibilities for compact, energy-efficient heat pump systems.

Kaltra will continue to expand testing and customization programs in close collaboration with OEM partners to ensure optimal integration of the new coils into various system architectures and refrigerant types.

The new microchannel evaporator coils are now available for sampling and specification in heat pump, air-conditioning, and process-cooling applications, with mass production already underway.

For technical details, performance data, or cooperation inquiries, please contact Kaltra’s engineering team or visit www.kaltra.com.

Headquartered in Germany and Austria, Kaltra is a leading developer and manufacturer of advanced microchannel heat exchangers (MCHEs) and thermal management solutions.

Kaltra specializes in the engineering and production of high-performance MCHEs for use in condensers, evaporators, and air-to-fluid heat transfer applications. The company offers a broad range of microchannel coils tailored for compact and energy-efficient cooling and heating systems.

Beyond its core MCHE expertise, Kaltra designs and manufactures a full lineup of air conditioning and refrigeration equipment, including air-cooled, water-cooled, and free cooling chillers; precision air conditioners; and IT cooling solutions such as room-, row-, and rack-based systems. Its product portfolio also includes air-cooled condensers, dry coolers, and specialized cooling units, all engineered for performance, reliability, and energy savings.

All Kaltra products are developed with a clear focus on maximizing energy efficiency, minimizing refrigerant charge, and reducing total cost of ownership.

For more information on Kaltra and its products, call +1 800 875 8975 or visit www.kaltra.com.