CLEANING

The aluminum surface is thoroughly cleaned to remove contaminants such as oils, grease, and dirt. This typically involves alkaline cleaning (degreasing), followed by rinsing.

DEOXIDIZING

A critical step to eliminate existing oxide layers or smut from the aluminum surface. This ensures optimal adhesion of the TCP coating.

RINSING

Multiple rinsing stages—using tap water and ultrapure water—are essential to remove residual cleaning and deoxidizing agents and to prepare the surface for coating application.

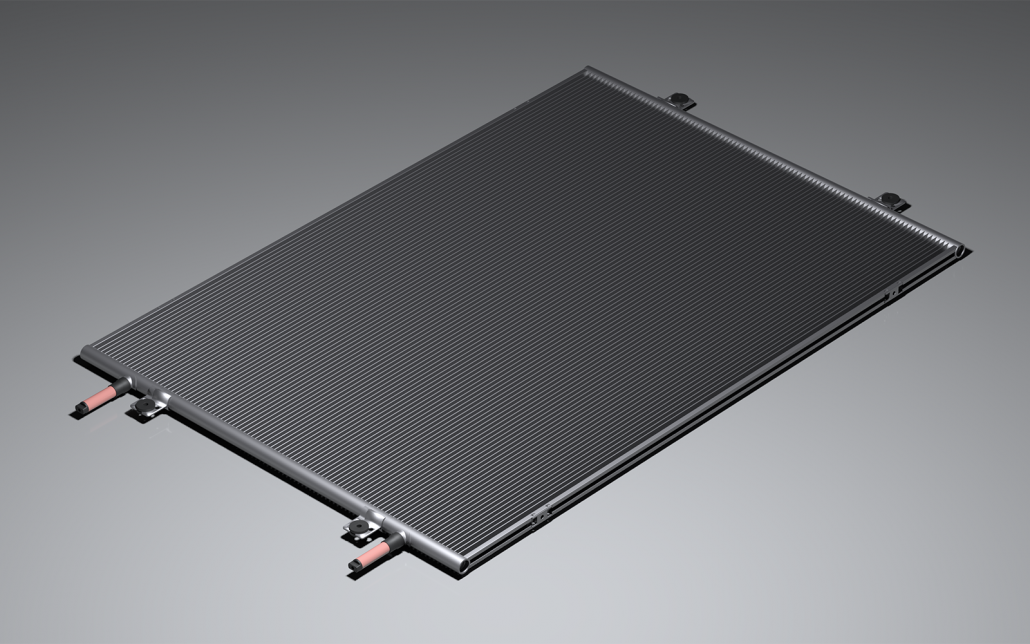

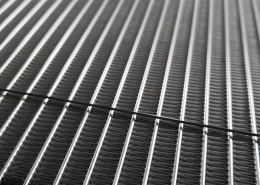

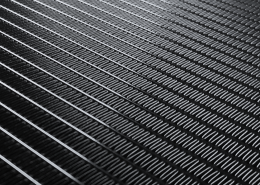

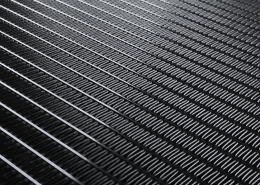

TRIVALENT CHROMIUM PASSIVATION

The TCP coating is applied by immersion in a trivalent chromium solution. The immersion time is carefully controlled to achieve proper coating formation, depending on the specific chemistry and desired thickness. TCP solutions typically contain trivalent chromium, fluoride and zirconate compounds, corrosion inhibitors, chelating agents, and other additives to enhance performance. The solution temperature is maintained within a defined range—usually at room temperature or slightly elevated—to ensure consistent coating quality. The process produces a colorless protective film with a thickness ≤3µm.

POST-RINSE

After coating application, the heat exchanger is rinsed with clean water to remove any remaining solution residues.

DRYING

The coated heat exchanger is dried at ambient temperature to allow the coating to cure and fully develop its protective properties.

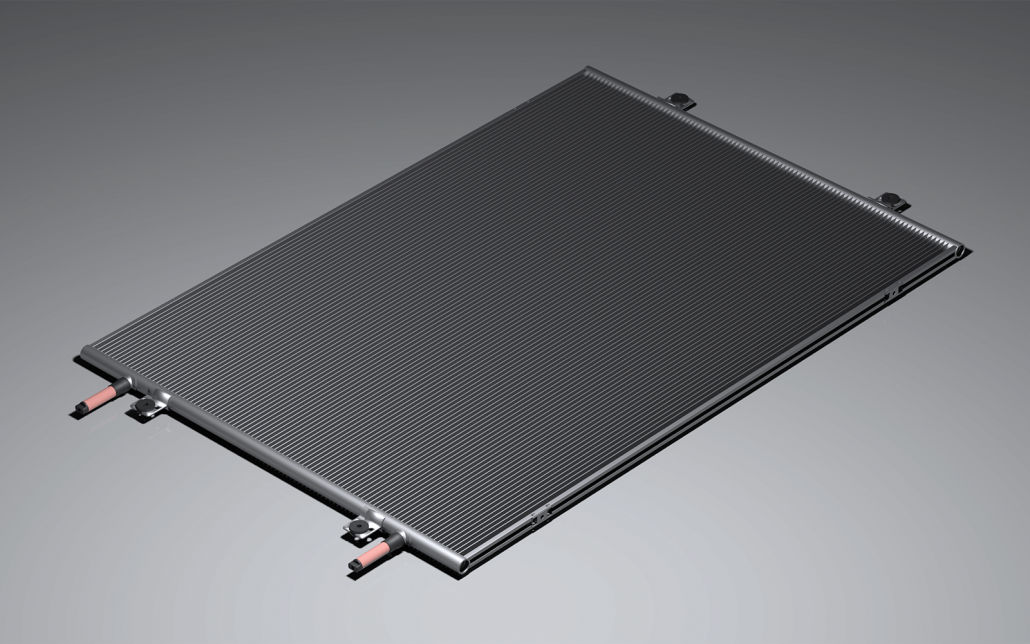

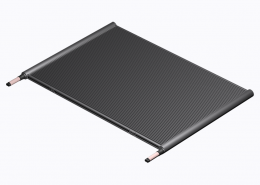

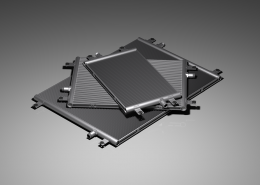

HELIUM LEAK TEST

After the coating process is complete, each coil undergoes a helium leak test to verify its integrity and ensure that no damage occurred during processing.