ELECTROPHORETIC COATING FOR MICROCHANNEL HEAT EXCHANGERS

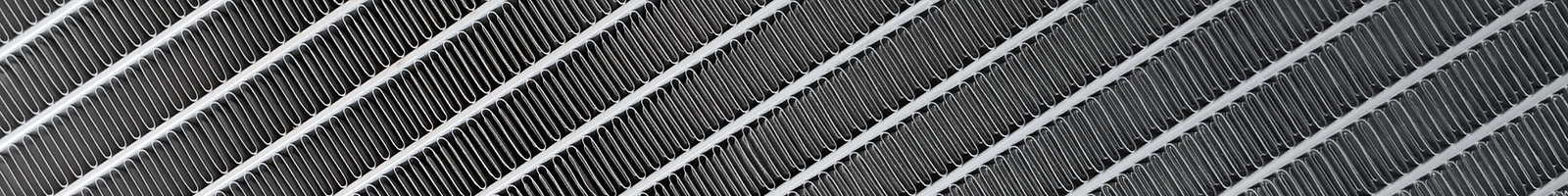

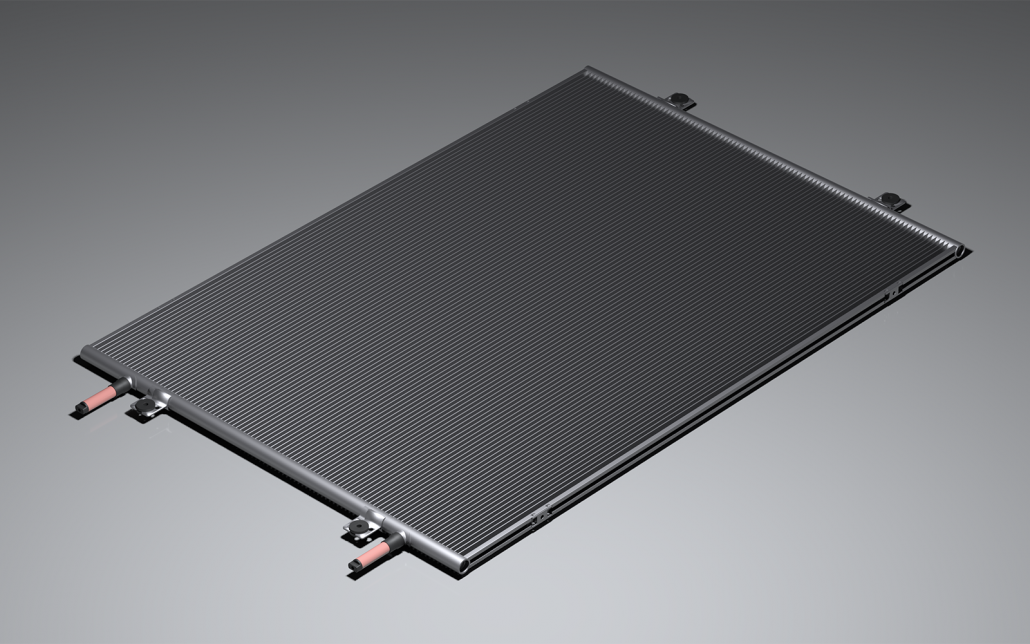

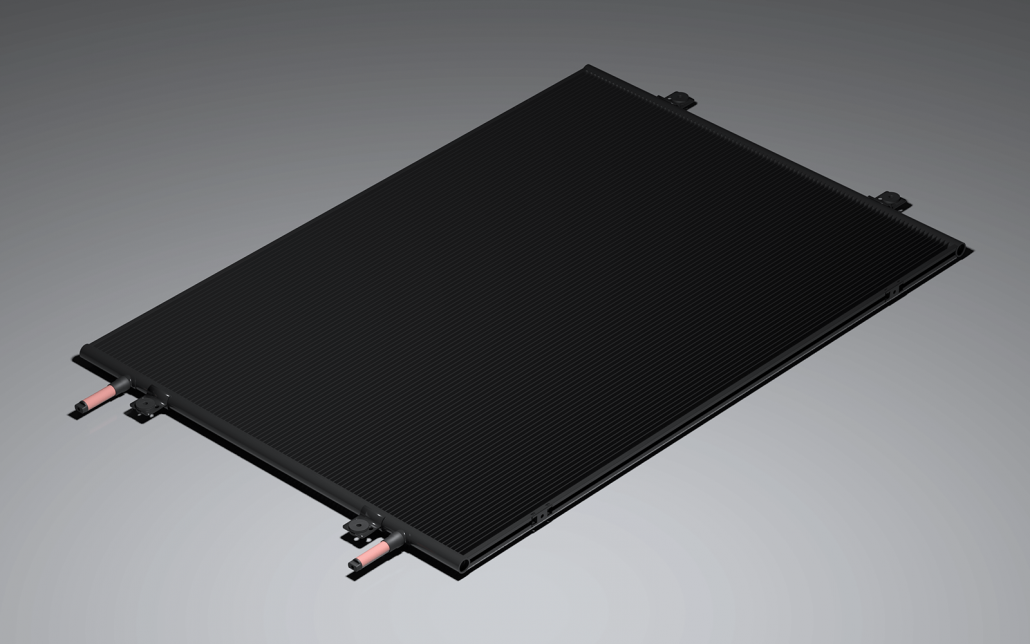

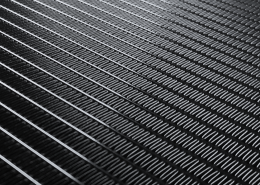

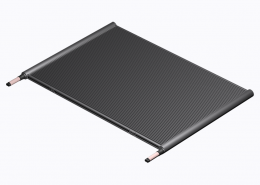

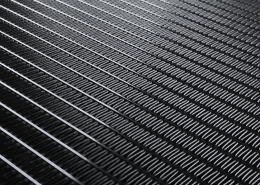

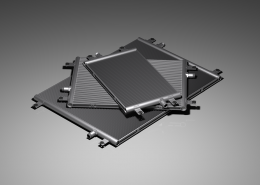

Electrophoretic coating, or e-coat, is an advanced surface treatment technology designed to protect conductive materials from corrosion—most notably aluminum alloys used in microchannel heat exchangers. Also known as electrocoating, electrodeposition, or electrophoretic painting, the process involves the application of an electric field to attract charged (epoxy) paint particles suspended in a water-based solution onto the surface of the heat exchanger, resulting in a uniform and durable coating.

E-coating is particularly effective due to its ability to uniformly coat complex shapes. It offers high paint transfer efficiency and is well-suited for automated, high-throughput production environments. The resulting coating layer is thin and consistent, minimizing any impact on the heat exchanger’s thermal performance. Notably, unlike many other coating methods, E-coating preserves the heat exchanger’s thermal conductance over time. Furthermore, e-coating is considered an environmentally friendly process.