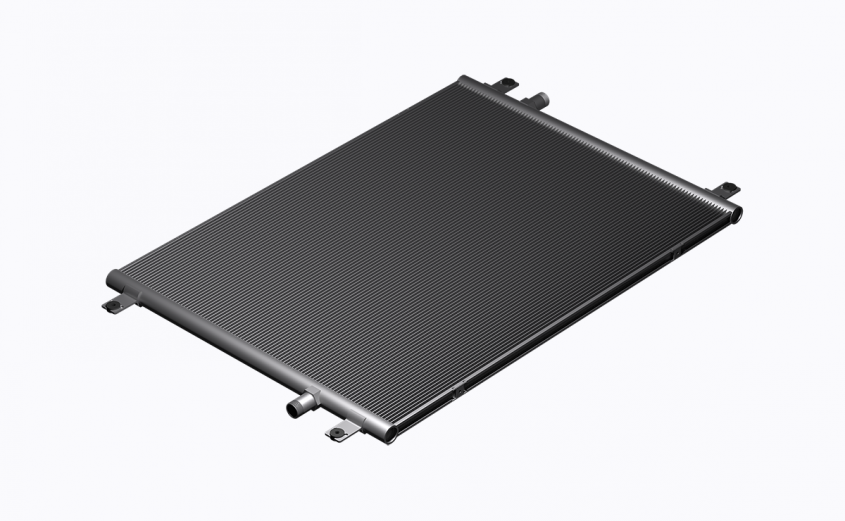

Chilled water coil design enhanced for application flexibility and extended lifespan

As part of its ongoing strategy to expand the applications and market reach of microchannel heat exchangers, Kaltra has introduced a new line of air-to-water microchannel coils, meticulously designed and optimized for specific uses.

The new coil series is tailored to serve the following key applications:

- Chilled water coils, such as free cooling coils

- Fluid coils designed for cooling and heating purposes

Engineered with a strong emphasis on application-specific performance, these coils feature advanced anti-corrosion treatments, compatibility with a broader fluid pH range, and an optimized design for efficient condensate drainage.

The new chilled water coil series uses a manganese-rich 3F05 aluminum alloy, delivering superior corrosion protection. This advanced material withstands over 6,000 hours of salt fog testing (SWAAT) without leaks or structural damage. Microchannel tubes are zinc arc-sprayed.

Corrosion resistance can be further enhanced with electrophoretic epoxy coating (e-coating) on the outer surfaces or nano-scale coating on both the outer and inner surfaces, making these coils perfectly suitable for C4 and C5 corrosivity zones. The nano-scale coating also allows compatibility with a broader pH range of working fluids.

The coil design has been optimized for fluid applications. Its vertical tube arrangement reduces fluid resistance for typical coil dimension ratios and facilitates effortless, gravity-driven condensate removal. Microchannel tubes with enlarged port sizes prevent clogging, even when handling contaminated fluids. Meanwhile, the tube wall thickness is maintained, ensuring coil reliability in harsh environments. Large-diameter inlet and outlet manifolds further reduce pressure losses in the coil and accommodate larger fluid connections.

Comprehensive field and laboratory performance analyses confirm that the new chilled water coils deliver valuable improvements in capacity, reliability, corrosion resistance, and resistance to environmental stress compared to previous designs.

Headquartered in Germany and Austria, Kaltra designs, develops, and manufactures air conditioning and refrigeration equipment and systems. The company offers air-cooled, water-cooled, and free cooling chillers, precision air conditioners, IT cooling systems, including room-, rack- and row-based solutions, and energy management solutions. It also designs and manufactures air-cooled condensers, dry coolers, and cooling units for special applications. Additionally, Kaltra offers microchannel heat exchangers for condenser, evaporator, and water cooling and heating applications, as well as aluminium coils for small cooling applications. All Kaltra products are engineered with the clear objective of improving energy efficiency and reducing total cost of ownership.

For more information on Kaltra and its products call +49 (0) 911 384 333 48 or visit www.kaltra.com