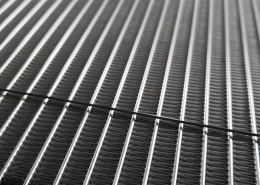

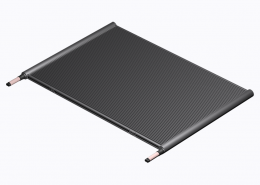

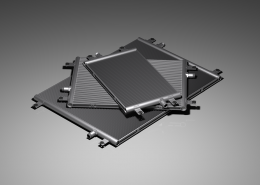

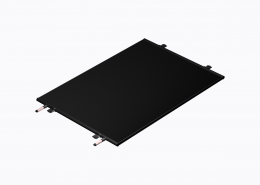

SUSTAINED PROTECTION

In addition to the use of advanced aluminum alloys, anti-corrosion coatings play a critical role in extending the service life of heat exchangers. The coatings we offer provide reliable, long-lasting protection—even in highly corrosive environments.

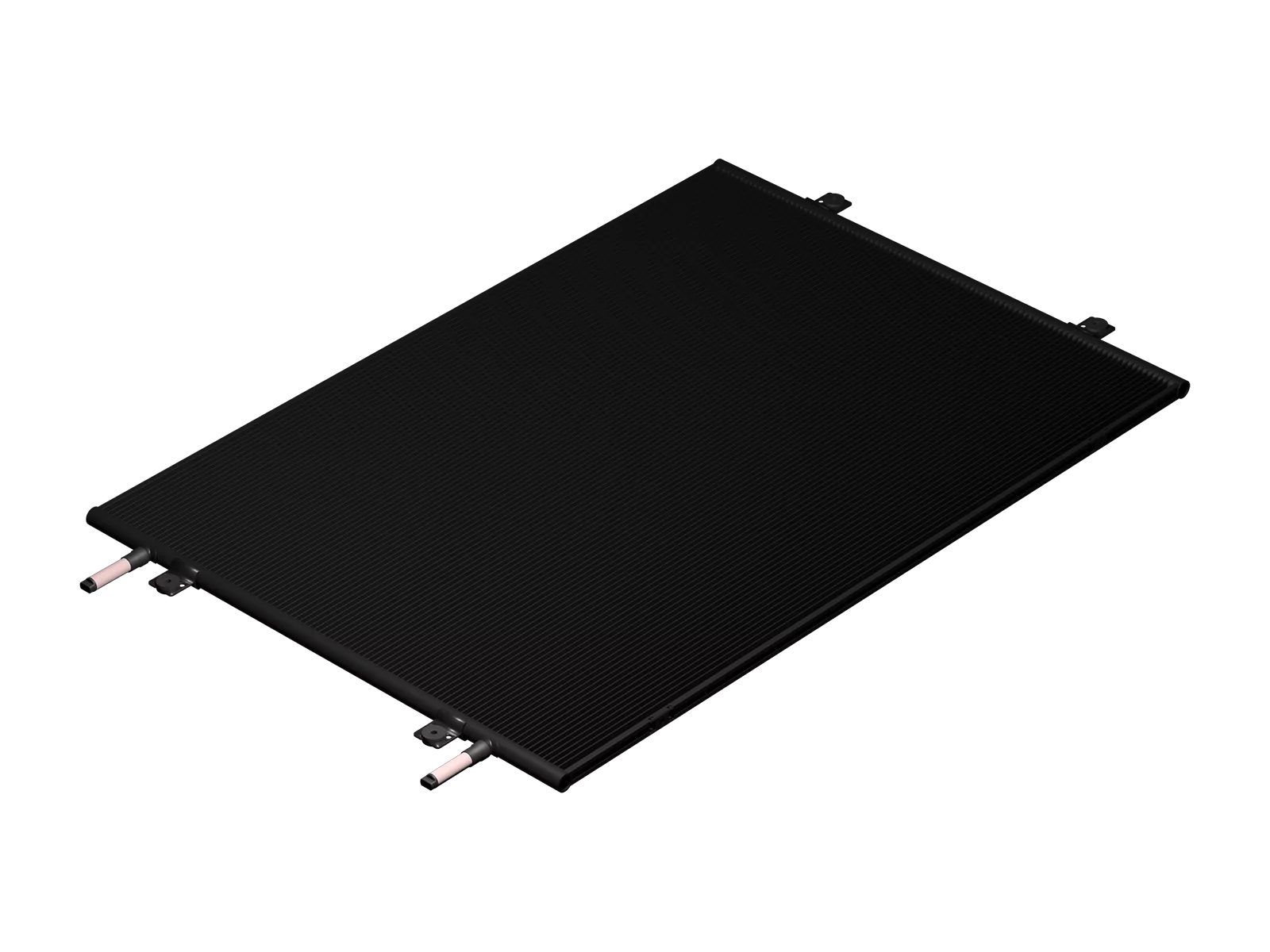

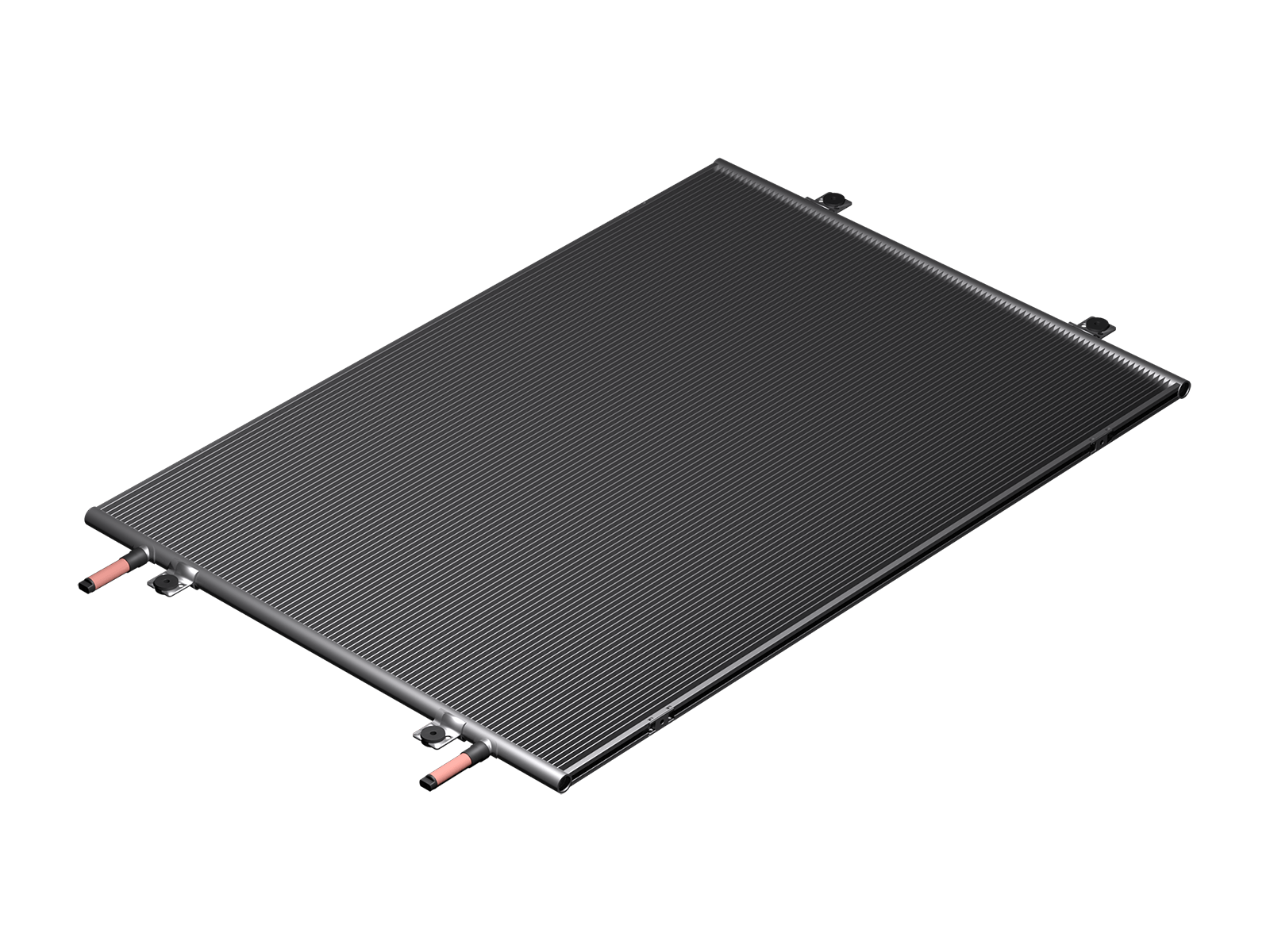

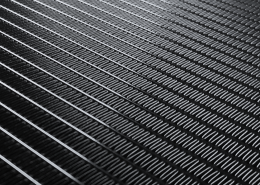

RESILIENT PERFORMANCE

Coatings provide more than just protection—they expand the operating range and enhance the performance of microchannel heat exchangers by improving temperature tolerance, compatibility with a wider range of fluids, and minimizing long-term performance degradation.

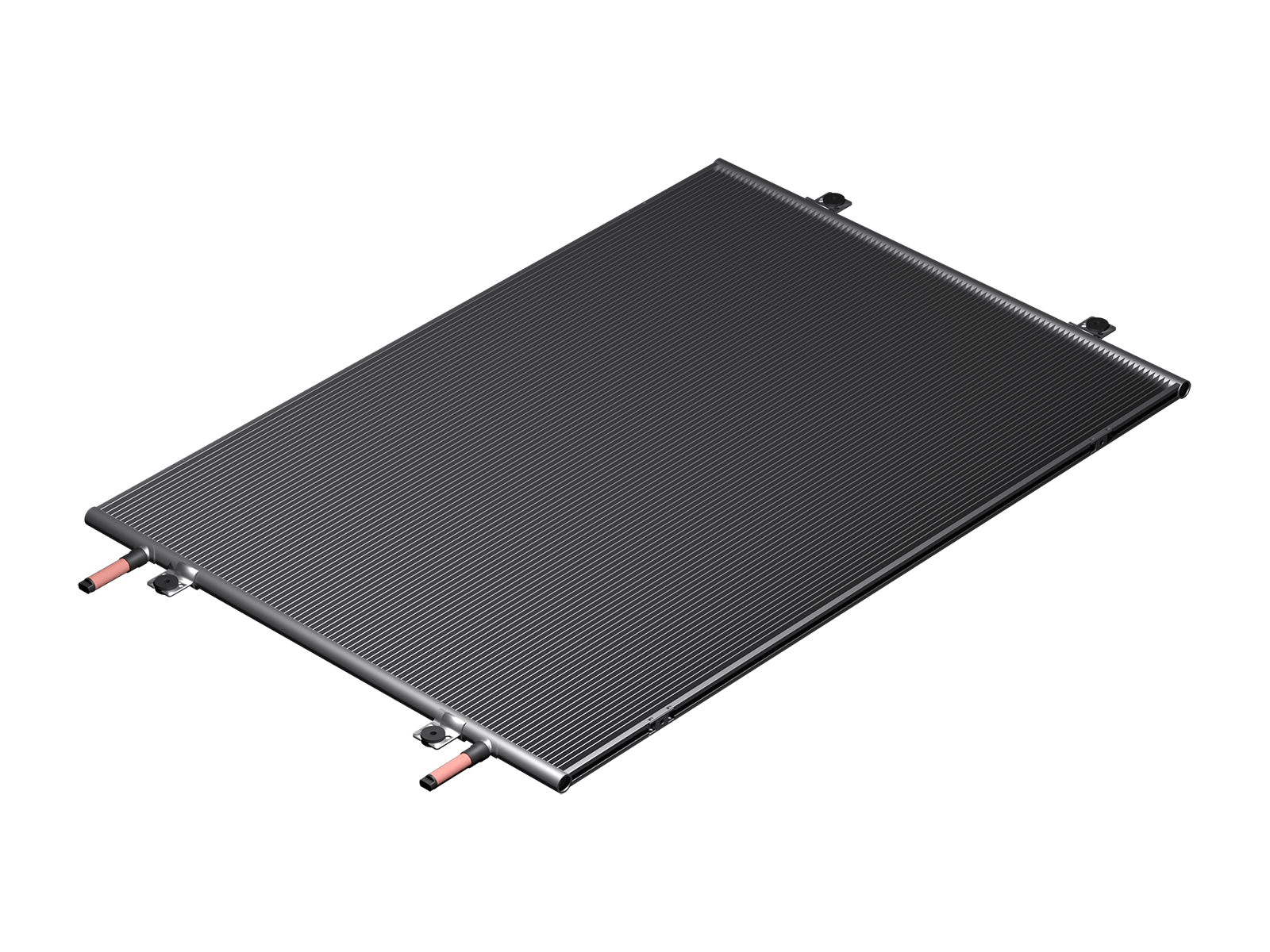

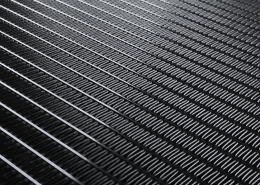

GREEN STEWARDSHIP

We prioritize sustainability by employing coating technologies that are environmentally safe. From the carefully engineered chemical formulations—free from harmful substances—to the controlled application processes that minimize waste and emissions, every aspect of our approach is designed to reduce environmental impact.