Hybrid dry coolers: a water-saving cooling solution

Closed-loop process cooling systems are gaining attention among a growing number of industries with the introduction of more stringent regulations on water use and increasing costs for water purchase and discharge. A hybrid cooling system where the dry cooling and evaporative cooling technologies are taken together is an attractive alternative to open-loop cooling towers in terms of both water saving and efficiency.

The basic operating principle of the hybrid dry cooler is rejecting the heat by means of latent, or evaporative, heat transfer. In a typical dry cooler system, the closed-loop fluid is cooled by sensible heat transfer and the approach temperature of a dry cooler is based on the dry bulb, while in a hybrid dry cooler equipped with evaporative cooling pads its approach temperature is based on the wet bulb which takes into account the moisture in the air stream and which is always lower than the dry bulb temperature. The warmer the climate, the more the efficiency of using hybrid dry coolers. Hybrid dry coolers are also a cost-effective technology for water conservation compared to water-intensive open-loop cooling systems where the water is constantly exposed to the ambient air.

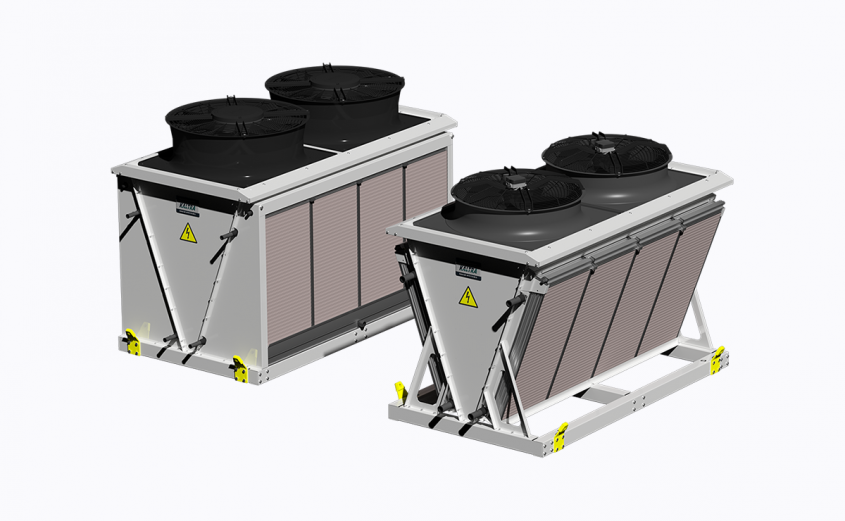

In order to fulfill the customer demand for efficient, water-conserving cooling systems, Kaltra launched a family of dry coolers with integrated direct evaporative pads to pre-cool the ambient air before entering the cooling coils. Evaporative media is made from finned aluminium and ensures the high evaporation efficiency, as well as the constant media pad cleanliness – a common problem the users face with cellulose-based evaporative media. At an air velocity of 2.0m/s, the saturation efficiency of the new evaporative media reaches 90 percent, compared to about 70 percent efficiency for cellulose-based media.

For small-to-medium installations, Kaltra offers evaporative dry coolers from its new Bora series, while Jumbo series fluid coolers are intended for large-scale applications. Both Bora and Jumbo dry coolers utilize microchannel air-to-water heat exchangers, thus offering high heat transfer rates and optimized fan power consumption thanks the low air pressure drops. Microchannel heat exchangers are made from the new long-life aluminium alloys which ensure the highest level of corrosion resistance. Additional coil protection (e-coating) for the seashore installations, or installations in high-polluted areas is also available as an option. Jumbo series dry coolers can also be equipped with an automatic heat exchanger cleaning system.

Kaltra is an HVAC engineering and manufacturing company headquartered in Germany. We offer a wide range of innovative cooling products for industrial, commercial, and mission-critical applications, such as data centers, clean rooms, contaminant-free areas, processing plants, and other facilities where the reliability and energy efficiency are key factors. Kaltra’s cooling equipment range includes precision cooling systems, air-cooled, free cooling and water-cooled chillers, evaporative cooling solutions, dry coolers, and condensers.

For more information on Kaltra and its products call +49 911 715-32021 or visit www.kaltra.de