Microchannel coil cleaner: could it be used or not?

Could chemical cleaners be used to clean microchannel coils? This is a common question among HVAC equipment owners and service teams. Many rely on recommendations found online instead of following manufacturers’ guidelines, frequently resulting in coil damage or destruction of its topcoat or progressive corrosion of the coil.

Chemical Cleaners

Despite many sources offering chemicals-based cleaners and declaring these are safe, Kaltra strongly advises against their use on microchannel coils. Instead, Kaltra recommends following manufacturer-approved cleaning methods to maintain coil performance and durability.

Microchannel coils are constructed from diverse aluminum alloys with varying clad materials and are often enhanced with specialized coatings for corrosion resistance, UV protection, and other benefits. However, these materials may react adversely to different groups of chemicals. As a result, no universal cleaner can be deemed safe for microchannel coils. Using unsuitable cleaners risks degrading coatings or base materials, potentially leading to performance loss and corrosion.

Manufacturers rigorously test microchannel coils in diverse environments with varying chemical pollutants, employing multiple cleaning and maintenance techniques. The findings are conclusive: no chemical cleaner is universally safe for microchannel coils.

Safe Cleaning Methods

Removing Debris

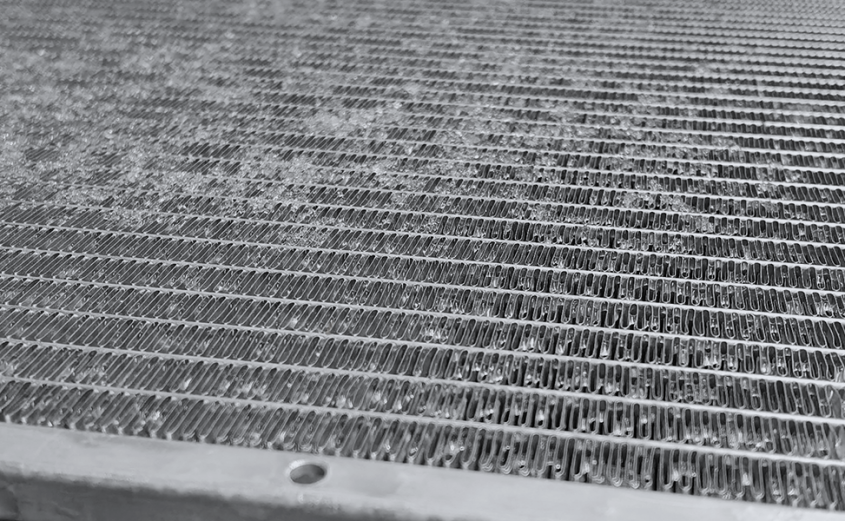

Cleaning microchannel coils is straightforward, facilitated by their minimal thickness and tightly spaced fin pitch. Surface debris, though uncommon, can be removed effectively with a soft brush, a vacuum cleaner with a soft attachment, or compressed air (3–5 bar). We recommend brushing the coil in the longitudinal direction of the fins to prevent damage.

Rinsing

Accumulated dust and dirt can be rinsed off using water with a pH between 4.5 and 8.5. A water-atomizing nozzle is ideal, as it prevents damage from concentrated water streams. For best results, angle the nozzle up to 25 degrees relative to the coil surface, ensuring water pressure does not exceed 40 bar. Maintain at least 400 mm between the nozzle and the coil surface during high-pressure cleaning, and always clean from the opposite direction of the normal airflow to push debris out rather than deeper into the coil.

Under negative ambient temperatures, where rinsing the coil with water could result in freezing, the preferred cleaning method is using compressed air to blow off dust and dirt.

Drying

After rinsing, Kaltra recommends drying the coil by blowing off or vacuuming out residual water.

Cleaning Schedule

The recommended cleaning interval for microchannel coils is every six months. However, cleaning intervals should be adjusted accordingly when operating in aggressive, corrosive, or highly polluted environments. The following signs may indicate the need for cleaning:

- Degraded unit performance

- Raised condensing temperature

- Increased fan speeds

Note that a lack of or inadequate or irregular cleaning may result in the voiding of the warranty for your heat exchanger.

Replacement Coils

If your microchannel coil fails due to cleaning with chemical agents, repair is generally not possible. Protective coatings applied by third parties are expensive and often unreliable, making coil replacement the only practical solution. In case you experience coil failure, Kaltra offers a wide spectrum of replacement coils for the most popular water chiller, condensers, and other cooling equipment, many of which are available in stock.