Microchannel coils fast becoming industry standard

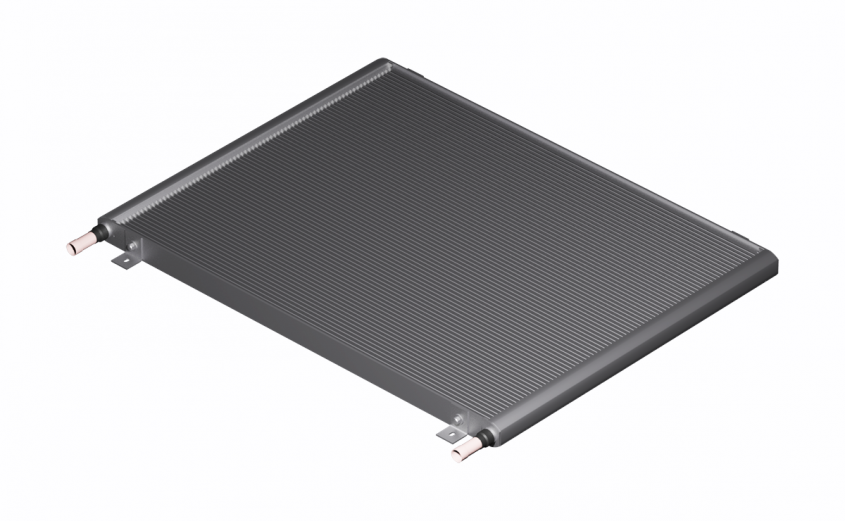

Since the introduction of the next generation all-aluminum microchannel coils, their acceptance in the process and HVAC industries has been nothing short of remarkable! The microchannel coil advantages are the future and rapidly becoming the norm because of the many benefits they provide in new HVAC equipment.

Alcoil’s microchannel technology sets the industry standard with wide reaching advantages especially for HVAC equipment. Equipment designers are able to take advantage of flexible application and performance characteristics to design equipment that is more efficient, smaller in size and less expensive to build and maintain than ever before.

Equipment strategies incorporating Alcoil condensers span a wide range of system designs. These include HVAC chillers, process chillers, data center systems, rooftop installations, airside equipment, environmental chambers, food and beverage, industrial process equipment and mission critical military equipment.

The Alcoil line of microchannel coils has expanded to evaporators for use in cooling, indoor and outdoor coils for heat pump applications, make up air, and dehumidifier coils. The reasons for Alcoil microchannel tremendous acceptance is the technology and company behind the product.

Alcoil manufactures in York, Pennsylvania and has the largest production brazing furnaces in the U.S. In addition, Alcoil has easy to use software to support standard and custom product applications. Microchannel aluminum coils are used by many major HVAC manufacturers worldwide.

Small footprint for chiller applications:

In comfort cooling and process cooling, microchannel coils being used to increase energy efficiency and reduce chiller footprint. Overall chiller weight is reduced, as well as refrigerant charge. Because of lower airside pressure drop, lower fan noise is possible.

Custom rooftop HVAC systems use smaller refrigerant charge with greater performance:

Custom rooftop systems use microchannel coils as condensers, evaporators and reheat coils. Easy packaging, up to 60% lower refrigerant charge, and high performance allow demanding specs to be met or exceeded.

Data center cooling systems with more flexible designs:

Microchannel coils are the high tech solution in the cloud, tailored to data center use that is setting record energy efficiency and ultra-low PUE. Approach temperatures of 1°C are possible as evaporators and water- cooled coils, while remaining 50% less weight and easy to package.