Aluminum coils: recommendations for cleaning

by Carter Stanfield

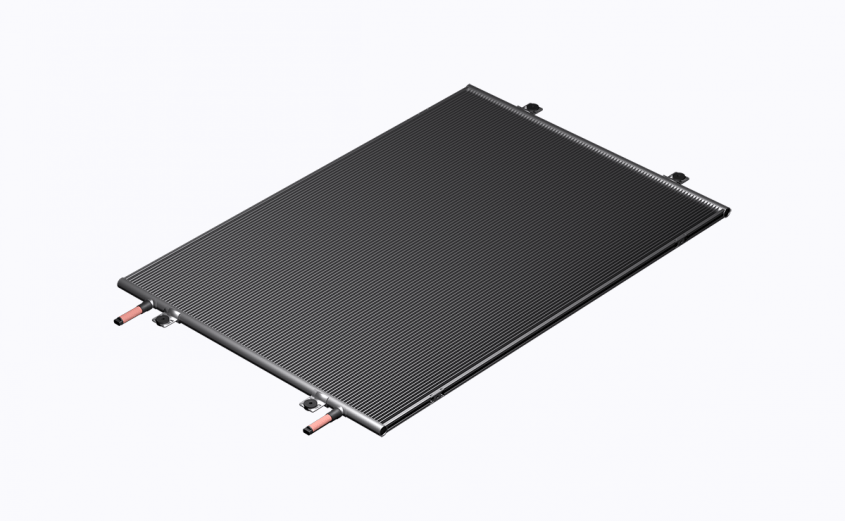

Aluminum coils are here to stay. Not only have they been applied successfully for years by Kaltra in their spiney fin condenser coils, they have also been used for years as evaporator coils in refrigerators.

Now several major air conditioning equipment manufacturers are viewing aluminum coils as a potential solution to the industry wide plague of formicary corrosion in copper tube aluminum fin evaporator coils. Many manufacturers now use all aluminum tube and fin coils in their indoor coils for air conditioning and heat pump systems. Kaltra uses all-aluminum microchannel coils for their indoor coils, and is researching the use of microchannel indoor coils.

In short, you really need to be prepared for aluminum coils regardless of how you feel about them. I confess to having a prejudice against aluminum coils. One of my issues is the difficulty of repairing aluminum coils. But truthfully, today’s copper tube and aluminum fin coils are not very repairable either. The copper is so thin that it is very difficult to braze. And brazing micro leaks from formicary corrosion is a losing proposition. You plug this tiny hole and leave 3 others. Or 3 more form a week after you leave.

The biggest two service differences come in coil cleaning and system charging. Most manufacturers recommend only water to clean aluminum coils. The wrong chemicals can eat them up. As with any indoor coil cleaning, if you do use a chemical – make sure it is approved for use on indoor coils. Using an outdoor coil cleaner on an indoor coil can cause noxious fumes for quite a while. Some chemical companies do manufacture coil cleaners that are approved for use on indoor aluminum coils. One thing you might look for is NSF approval. A cleaner used on refrigeration equipment around food must be NSF approved. While not necessary for air conditioners, an NSF approval should mean that there would be no toxic fumes. For more information on cleaning aluminum coils look at these instructions from Kaltra and SpeedClean.

Carter Stanfield is Program Director of the Air Conditioning Technology Department at Athens Technical College, where he has taught since 1976. His industry credentials include both an RSES CM and NATE Certification and a State of Georgia Unrestricted Conditioned Air Contracting License.

Kaltra is a world-known provider of cooling technologies and advanced cooling products for mission-critical applications, such as data centers, clean rooms, contaminant-free areas, processing plants, and other facilities where reliability and energy efficiency are key factors. Kaltra’s cooling equipment range includes precision cooling systems, air-cooled and water-cooled chillers, evaporative cooling solutions, dry coolers, and condensers.

For more information on Kaltra and its products call +49 911 715-32021 or visit www.kaltra.de