Methods of microchannel coils defrosting

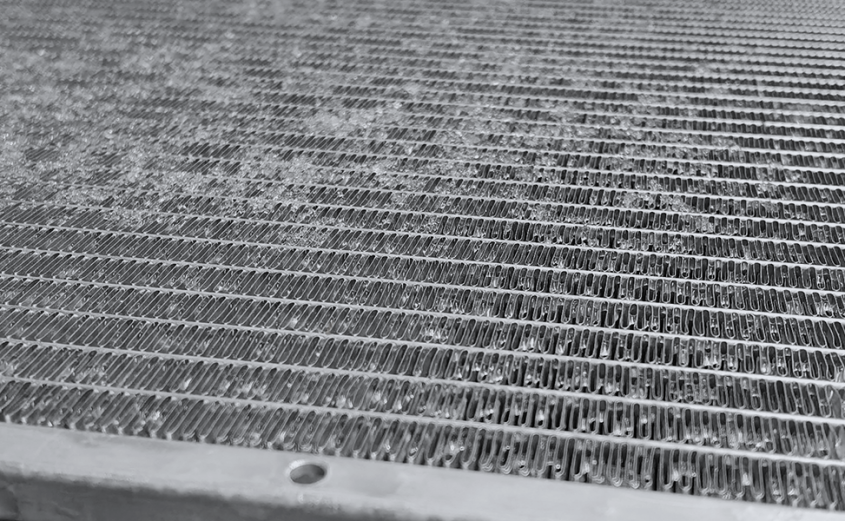

Microchannel coils are becoming quite popular as an alternative to bulky finned tube heat exchangers. For the desired capacity, microchannel coils are smaller in size resulting in less refrigerant charge in the system, offer higher heat transfer performance, and lower weight. However, until now, microchannel coils used only to a very limited extent in HVAC units exposed to freezing conditions like heat pumps.

The defrosting issue is not easy to deal with. First, non-uniform surface temperature distribution caused by the unequal distribution of the refrigerant between the microchannel tubes results in uneven distribution of frost. The solution lies in using heat exchangers uniquely constructed for evaporator and heat pump applications, featuring inbuilt refrigerant distributors to ensure uniform feeding of refrigerant into the channels.

Fin surface temperature and air humidity are primary parameters that influence the frost growth rates, while water retention and air velocity have a secondary impact on frosting performance.

Microchannel heat exchangers with vertically oriented channels exhibit no water retention on the surface, and drainage water freely flows down during the defrosting process, making vertical coil design a preferred solution for evaporator and heat pump applications.

Selecting a larger fin pitch also leads to less air flow blockage due to the larger air pathway. In addition, heat exchangers with a larger fin pitch demonstrate a more uniform build-up of frost on the surface.

According to empirical testing, compared to finned tube heat exchangers, microchannel coils require a considerably shorter time between defrost cycles but defrost cycle time for microchannel heat exchangers is about 25% shorter.

The following methods of defrost control can be adopted for microchannel coils:

Electric Defrost

The most common method of defrosting is by an electric heater. Although simple to install and control, electric defrost may be expensive in terms of energy consumption. The electric heater is energized for the duration of each defrost cycle, and this may lead to significant power consumption of the HVAC system.

Off-Cycle Defrost

Off-cycle defrost simply involves turning off the refrigeration system while letting the fans run continuously. Since the air must be warmer than 0˚C, off-cycle defrost is only useful on coolers for the storage of beverages and produce. The main advantage of off-cycle defrost is the simplicity and economy of installation.

Hot Gas Defrost

This is the most complex defrost system, based on the quality and effectiveness of the hot gas defrost, and it is better than the other defrost methods. In hot gas defrost, the liquid refrigerant flowing through the evaporator is interrupted, and instead, a supply of gas directly from the discharge of the compressor is used. The hot discharged gas applies heat to the frost where it forms on the microchannel coil. The hot gas travels throughout the entire circuit, and will, therefore, defrost areas of the evaporator that may not be as effectively reached by electric resistance heaters. In some applications, especially for cold storage rooms, the flow of the hot gas is in the reverse direction compared to that of the cooling mode (reverse cycle hot gas defrost).

Continuous Defrost

Continuous defrost involves sequential closing and opening of independent microchannel coil segments for off-cycle defrosting. When one coil segment needs to be defrosted, the control system shuts it off, while remaining segments allow the evaporator to function normally. Closed segment will be opened as soon as frost is removed from it by running fans, while the next segment will be closed for defrosting.

***

For systems with microchannel coils, the defrost system shall be activated when it detects there’s a small chance of frost forming by reading from the ambient temperature sensor and refrigerant pressure sensor to control the decrease in pressure of the refrigerant at the output of evaporator. When the measured pressure decreases below a threshold value, this is indicative of ice build-up.

Even though microchannel heat exchangers have a shorter frost cycle in comparison to finned tube heat exchangers, defrosting methods for microchannel coils are still the same. Uniform refrigerant distribution, selecting suitable fin pitch and geometry, free water run-off are crucial for the performance of microchannel coils operating in frosting conditions.

Kaltra is a world-known provider of cooling technologies and advanced cooling products for mission-critical applications, such as data centers, clean rooms, contaminant-free areas, processing plants, and other facilities where reliability and energy efficiency are key factors. Kaltra’s cooling equipment range includes precision cooling systems, air-cooled and water-cooled chillers, evaporative cooling solutions, dry coolers, and condensers.

For more information on Kaltra and its products call +49 911 715-32021

or visit www.kaltra.de