Microchannel heat exchangers for refrigeration systems running on R32 and other flammable refrigerants

High global warming potential refrigerants for refrigeration systems are being phased out because they are one of the culprits of climate change, while, at the same time, nearly 50 alternative refrigerants are classified as environment-safe.

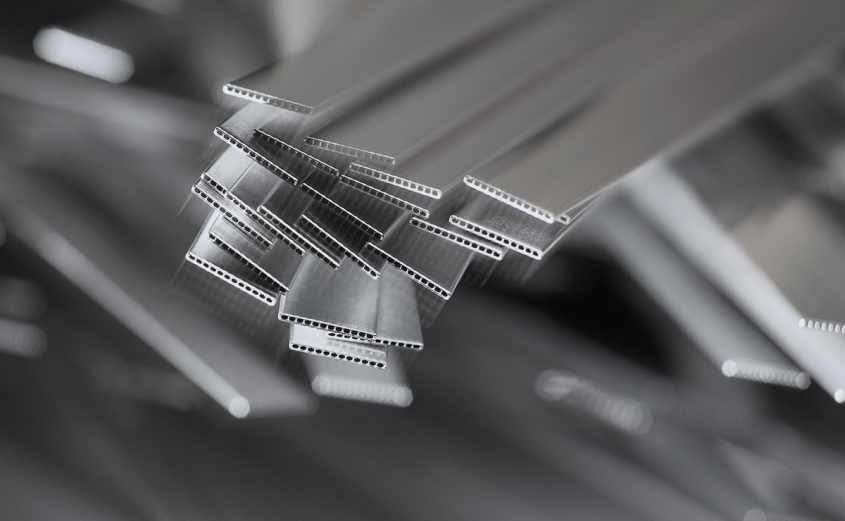

The most promising low-GWP refrigerants, including trending R32 – organic hydrofluorocarbon compound – however, flammable, and charge quantity for indoor applications, for this reason, is limited for these gases. In 2019, the International Electrotechnical Commission (IEC) revised safety standard IEC 60335-2-89, increasing charge limits for flammable refrigerants. The charge limits have increased from 150g to 500g for A3 flammability class refrigerants, as well as for mildly-flammable A2 and A2L gases from 150g to 1200g (per refrigeration circuit). However, higher limits only apply to a limited number of applications and only in rooms of a certain size – to prevent the creation of an explosive atmosphere in the case of a leak. For instance, the charge amount of R32 with its lower flammability limit (LFL) of about 0.306kg/m3 for a 20m2 room is relatively small: the maximum system charge must not exceed 4.5kg (for wall-mounted appliances), which is far above the limit. Allowable charge amounts for A3 hydrocarbons like propane (R290) and isobutane (R600a) are even smaller. Traditional finned-tube evaporator plus condenser charge combined count for approximately 40-50% of the total system charge. Therefore, reducing the charge of both of these components can greatly influence the minimization of the total charge of the system. Significant charge reduction is possible with the use of microchannel heat exchangers (MCHE). Typically, microchannel condensers and evaporators have about 60% less internal volume compared to finned-tube coils, contributing to a substantial charge amount reduction for the system. In small cooling appliances with headerless, serpentine-type microchannel coils, charge reduction can reach as much as 95%.

|

Heat exchanger design |

Finned-pack coil |

Parallel-flow MCHE |

Serpentine-type MCHE |

|---|---|---|---|

|

Purpose |

Condenser |

Condenser |

Condenser |

|

Dimensions (WxH) |

500x500mm |

500x500mm |

450x450mm |

|

Refrigerant |

R32 |

R32 |

R32 |

|

Capacity |

3.85kW |

4.10kW |

4.25kW |

|

Internal volume |

1.125L |

0.580L |

0.205L |

Apart from charge reduction, microchannel heat exchangers offer numerous other advantages over traditional, mechanically-assembled coils:

- Reliability and long service life – properties necessary for systems running on flammable and/or toxic gases:

- Integrally-brazed construction offers high robustness resistance to mechanical damages

- Resistance to different types of corrosion

- Performance: brazed nature of heat exchangers delivers heat transfer rates that cannot be achieved using mechanical joints

- Weight and space reduction

- Lower cost. Easy to recycle

For heat exchangers intended for use with flammable or toxic freons, Kaltra offers special aluminum alloys, high-grade fluxes, and advanced testing techniques to ensure safe and lasting operation.

Having a specialty and extensive experience in designing and manufacturing condensers and evaporators targeting flammable refrigerants, natural or synthetic, we offer best-in-class solutions for small and medium-sized applications.