Highly efficient Turbocor-based chillers

From an energy usage point of view, chillers are the most energy-intensive equipment to run and the key components within a chiller that impact performance and energy consumption are compressors. Turbocor compressors with built-in variable speed control can offer substantial energy savings of 50-60% compared to chillers equipped with fixed-speed compressors. In addition to the stepless capacity control, the Turbocor compressors employ built-in inlet guide vanes to trim the compressor capacity at low loads.

What’s more, the oil-free design of Turbocor compressors optimizes heat transfer: as oil accumulates on heat transfer surfaces in a lubricated chiller, its heat transfer efficiency drops by 15-25%. As a consequence of oil elimination, better heat transfer in the evaporator or condenser vessels will improve resulting in smaller approach temperatures. The pressure ratio that the compressor has to deliver reduces as a result of the smaller approach temperatures.

Other benefits of oil-free design include substantial reliability improvements, reduction in maintenance costs, and simpler system design which eliminates oil management components such as oil separators, oil controls, oil pumps, oil safety devices and simplifies piping arrangement.

Unlike a conventional chiller that can draw huge current when starting, Turbocor compressor pulls only a few amps at start-up, which avoids start-up demand spikes, smooths the system load and reduces thermal stress on internal motor components.

Opposed to a lubricated chiller, the year-round energy savings of a Turbocor-based chiller can exceed 35%. Since the vast majority of industrial and HVAC installations are part-load applications, Turbocor chillers with smooth capacity control offer huge savings from a life-cycle perspective.

The combination of part-load operating efficiency, oil-free design, and quietness is attractive for the customers in many industries, including manufacturing, chemical, electronics, automotive, office buildings, hospitality, and pharmaceuticals segments.

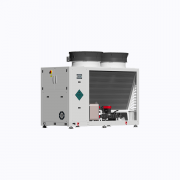

Kaltra’s Powerstream Turbo chiller family addresses the customers’ demand for efficient, capacity-matched cooling, high system reliability, and low maintenance costs. In the water-cooled Powerstream Turbo chiller, up to six Turbocor compressors are configured in parallel. That allows each compressor to turn on and off to handle low loads. The control system can determine a decrease in inlet guide vane position and can begin monitoring the power consumption. When the cooling demand can be carried more efficiently by less number of compressors, additional compressors are shut off, thus assuring an optimum chiller efficiency.

Flooded evaporators and condensers used in Powerstream Turbo design are optimized to ensure close approach temperatures, uniform refrigerant evaporation, and minimum pressure drops. Powerstream Turbo supports the outlet water temperatures of up to 20°C, thereby making it suitable for wide variety of applications, from process cooling to data center cooling to comfort cooling applications.

The Powerstream Turbo range offers a 300-4500kW cooling capacity with R134a and R1234ze refrigerants. The range is compliant with the European Energy-related Products Directive (ErP) and Ecodesign Directive.

Kaltra is an HVAC engineering and manufacturing company headquartered in Germany. We offer a wide range of innovative cooling products for industrial, commercial, and mission-critical applications, such as data centers, clean rooms, contaminant-free areas, processing plants, and other facilities where the reliability and energy efficiency are key factors. Kaltra’s cooling equipment range includes precision cooling systems, air-cooled, free cooling and water-cooled chillers, evaporative cooling solutions, dry coolers, and condensers.

For more information on Kaltra and its products call +49 911 715-32021 or visit www.kaltra.de