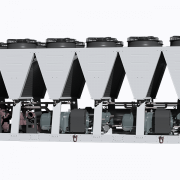

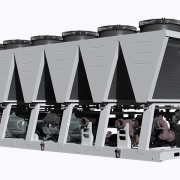

Kaltra reveals the new Ultracompact II product line

As a part of its long-term product development roadmap, Kaltra Innovativtechnik introduces the next generation of its Ultracompact product line. This series covers the cooling duty range between 50 and 300kW with capacity increases of 25kW and provides total or partial heat recovery in compact machine design and suitable for air-cooled applications across many industries.

Powered by scroll compressors, the units deliver best-in-class energy efficiency with average EER of 3.35 based on innovations in heat exchanging technology used by Kaltra. “We have used several innovations: advanced microchannel condensers which help to reduce condensing temperatures, and brazed all-aluminium corrugated plate evaporators that enable higher evaporation temperatures. The synergy effect promotes significantly higher overall efficiency with EER of up to 3.50,” said Mr. Helmut Brand, chief engineer, Kaltra. Additionally, the new Ultracompact II lineup includes a solution for direct evaporative cooling with pads and integrated water distribution system. “Kaltra collaborates with a lot of customers located in hot climate zones, and the new evaporative solution will provide them with a more efficient way of cooling,” Mr. Brand adds. The evaporative media are made of non-organic aluminum fins with an anticorrosion coating. The fin technology is a combination of a special finned structure and water-retaining coating, designed to keep pressure drop to a minimum while delivering evaporation efficiencies that exceed 90%. Depending on ambient temperature and air velocity, evaporative pre-cooling allows reducing the condenser entering air temperature for up to 10°C at the humidity of 50%. Equipping Ultracompact II chillers with evaporative pads results in significant electricity savings of up to 30% and even higher.

The evaporative cooling system can be equipped with circulator pump and water monitoring and treatment for water reuse.

New chillers are designed for easy maintenance: all side panels are removable to access the components of refrigerant and water circuits; evaporative pads can also be detached for cleaning and accessing the condenser coils.

The Ultracompact II series chillers are also available with integrated heat recovery, total or partial.

The next generation Ultracompact II chillers will be produced at the new Kaltra factory in Slovenia.

In 2018, Kaltra is planning to extend the Ultracompact II range with free cooling models which, in synergy with evaporative pads option, offer great free cooling opportunities and excellent seasonal efficiency. Free cooling system will be based on microchannel heat exchangers with low airside pressure drop.

Kaltra is a world-known provider of cooling technologies and advanced cooling products for mission-critical applications, such as data centers, clean rooms, contaminant-free areas, processing plants, and other facilities where reliability and energy efficiency are key factors. Kaltra’s cooling equipment range includes precision cooling systems, air-cooled and water-cooled chillers, evaporative cooling solutions, dry coolers, and condensers.

For more information on Kaltra and its products call +49 911 715-32021

or visit www.kaltra.de