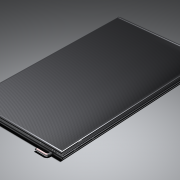

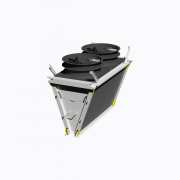

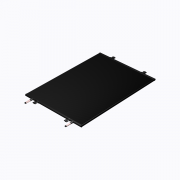

Kaltra unveils next-generation microchannel evaporator coils – engineered for reversible operation and peak efficiency

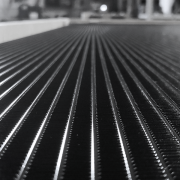

Uniform refrigerant distribution and effective condensate drainage have long been among the main engineering challenges in microchannel evaporator design. While Kaltra’s previous coil generations successfully solved these aspects individually, certain demanding conditions — such as low-load operation, frosting, or use in reversible heat-pump systems — continued to push design limits.