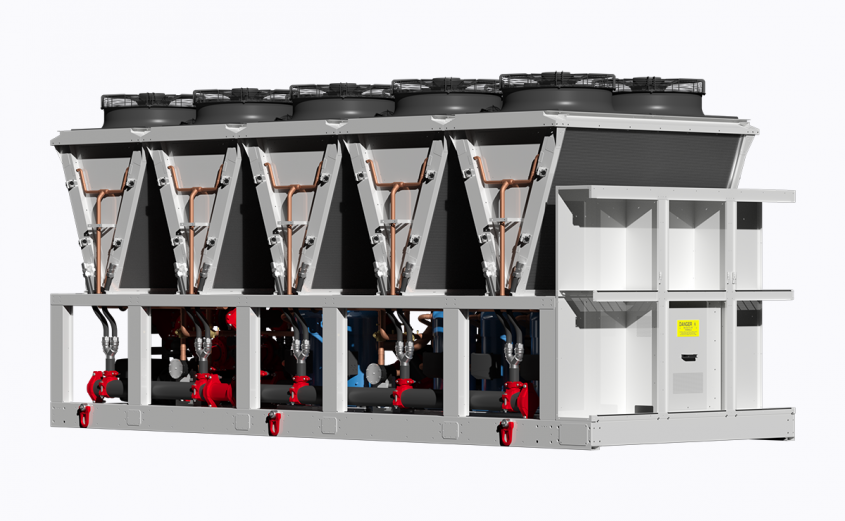

V-shaped microchannel coils for chiller applications

The efficiency of air-cooled chiller is dictated by the condensing temperature, which may be decreased with increasing heat transfer performance of the condensing coil. Microchannel heat exchangers have become popular in chiller applications due to better thermo-hydraulic characteristics in comparison to conventional finned tube heat exchanger designs. The most straightforward way to improve heat exchanger performance is to increase its face area by combining two microchannel coils in V form.

Field tests showed that the V-shaped microchannel heat exchangers used in Kaltra’s new ranges of air-cooled chillers increase the capacity of condensers by 20% with the same footprint. At the same capacity, the new heat exchanger results in around a 2K drop in the condensing temperature, thereby increasing the chiller efficiency by more than 5%. Thin microchannel coil design also translates into significantly lower airside pressure drops, resulting in about a 10-percent reduction in fan power consumption.

For OEMs and end-customers, Kaltra offers highly efficient condenser banks, customized per application and suitable for use in air-cooled chiller and condenser applications.

Please contact Kaltra’s R&D Team for more details.

Kaltra is a world-known provider of cooling technologies and advanced cooling products for mission-critical applications, such as data centers, clean rooms, contaminant-free areas, processing plants, and other facilities where reliability and energy efficiency are key factors. Kaltra’s cooling equipment range includes precision cooling systems, air-cooled and water-cooled chillers, evaporative cooling solutions, dry coolers, and condensers.

For more information on Kaltra and its products call +49 911 715-32021

or visit www.kaltra.de